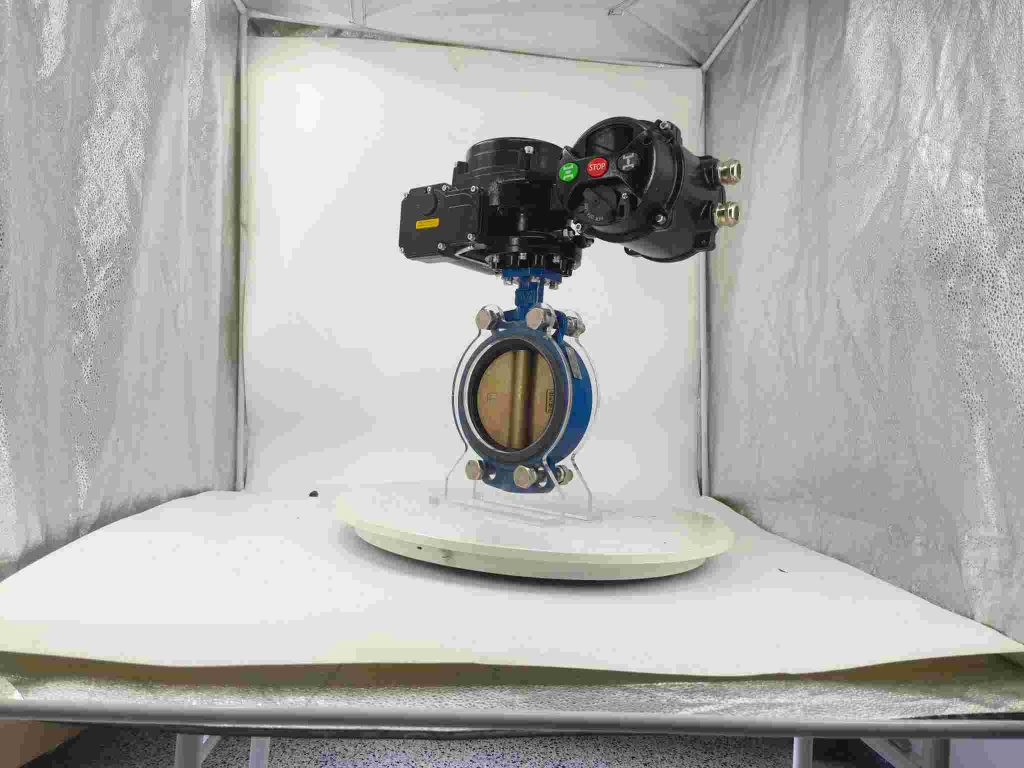

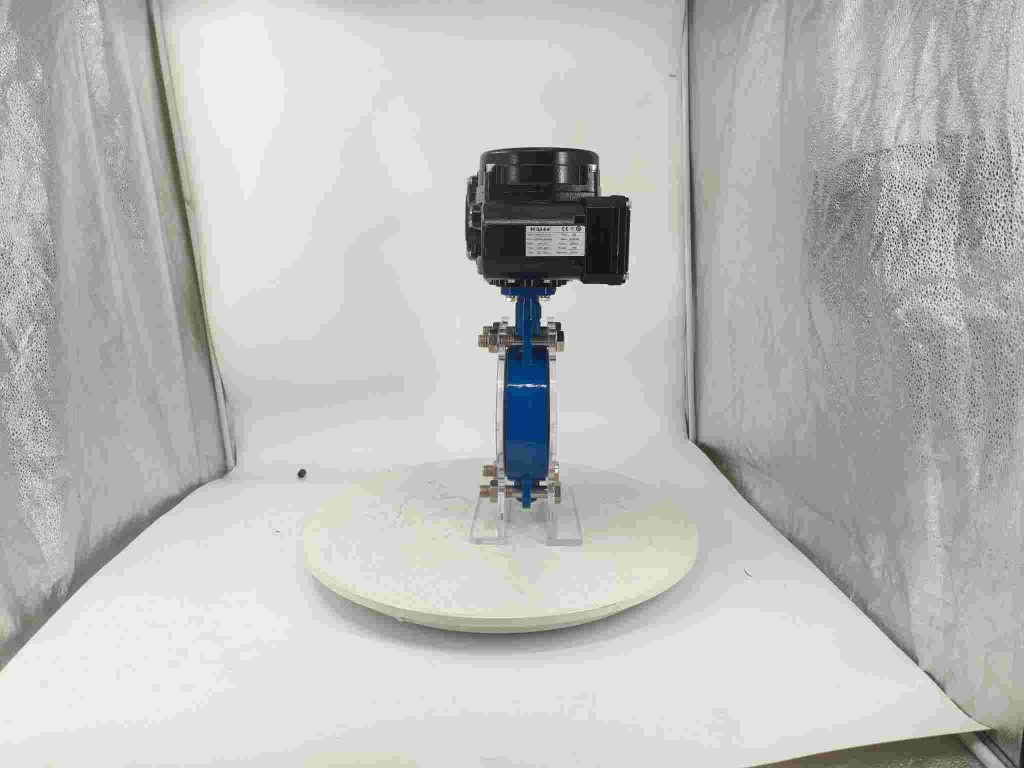

The WCB Electric Flanged Butterfly Valve is an essential component widely used in various industrial applications, including water treatment, oil and gas, chemical, and HVAC systems. Known for its durability, ease of operation, and efficiency, this type of valve plays a critical role in regulating fluid flow in pipelines. In this article, we will explore the design, functionality, and benefits of the WCB Electric Flanged Butterfly Valve, shedding light on why it has become a preferred choice for engineers and operators alike.

What is a WCB Electric Flanged Butterfly Valve?

A WCB Electric Flanged Butterfly Valve is a type of valve that uses a rotating disk, or “butterfly,” to control the flow of fluids. The “WCB” designation refers to the material used for the valve body, which is carbon steel. Carbon steel is commonly used for industrial valves due to its excellent strength, durability, and cost-effectiveness. The term “electric” signifies that the valve is operated electronically, typically through an electric actuator, which automates the opening and closing of the valve. The “flanged” refers to the type of connection the valve has to the pipeline, where flanges are used to bolt the valve securely into place.