In the world of industrial automation, control valves play a critical role in regulating the flow of fluids and gases across various systems. Among the most efficient and versatile types of valves are electric screw ball valves. These advanced valves are designed to meet the high demands of precision, reliability, and durability, making them an essential component in many industries such as oil and gas, water treatment, chemical processing, and more. This article explores the role of electric screw ball valve ODM (Original Design Manufacturer) manufacturers in providing high-quality, customizable solutions to meet the needs of modern industries.

Understanding Electric Screw Ball Valves

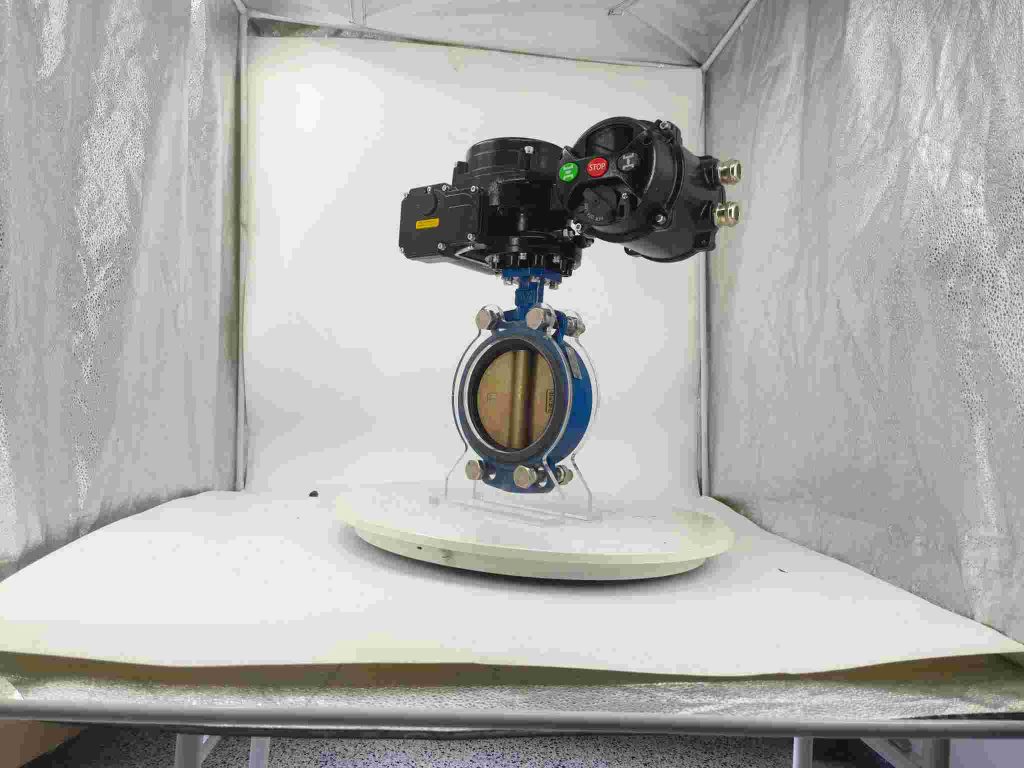

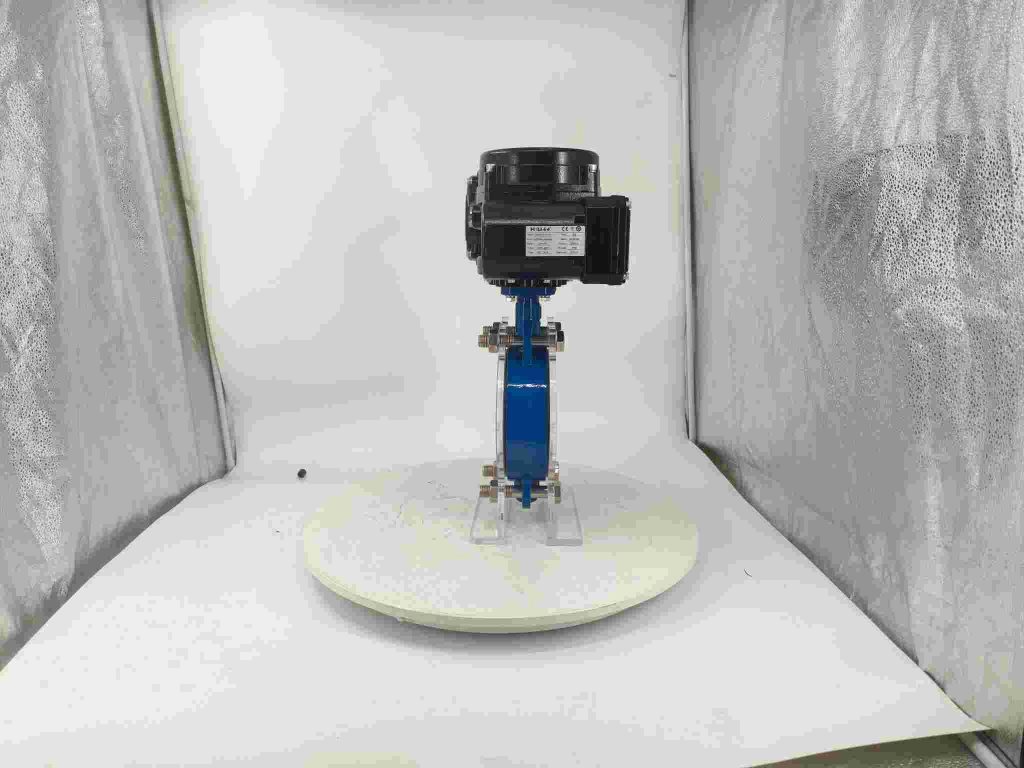

Electric screw ball valves combine the technology of ball valves with electric actuators to provide precise control over fluid and gas flow. The valve itself features a ball with a hole or port in the center that rotates to allow or block the flow of materials through the pipe. What sets electric screw ball valves apart is the integration of an electric motor or actuator, which automates the opening and closing of the valve, allowing for better control and efficiency. These valves can be remotely operated, making them ideal for applications where manual control is not feasible or desirable.