The WCB Electric Ball Valve is a crucial innovation in the field of fluid control systems. Widely used across various industries, including oil and gas, chemical processing, water treatment, and HVAC systems, the WCB Electric Ball Valve stands out for its precision, reliability, and durability. This valve combines the robust features of ball valves with the efficiency of electric actuation, providing a reliable solution for on/off and modulating control of fluids. In this article, we will explore the advantages of WCB Electric Ball Valves, their working mechanism, applications, and why they have become a go-to choice for modern industrial systems.

What is a WCB Electric Ball Valve?

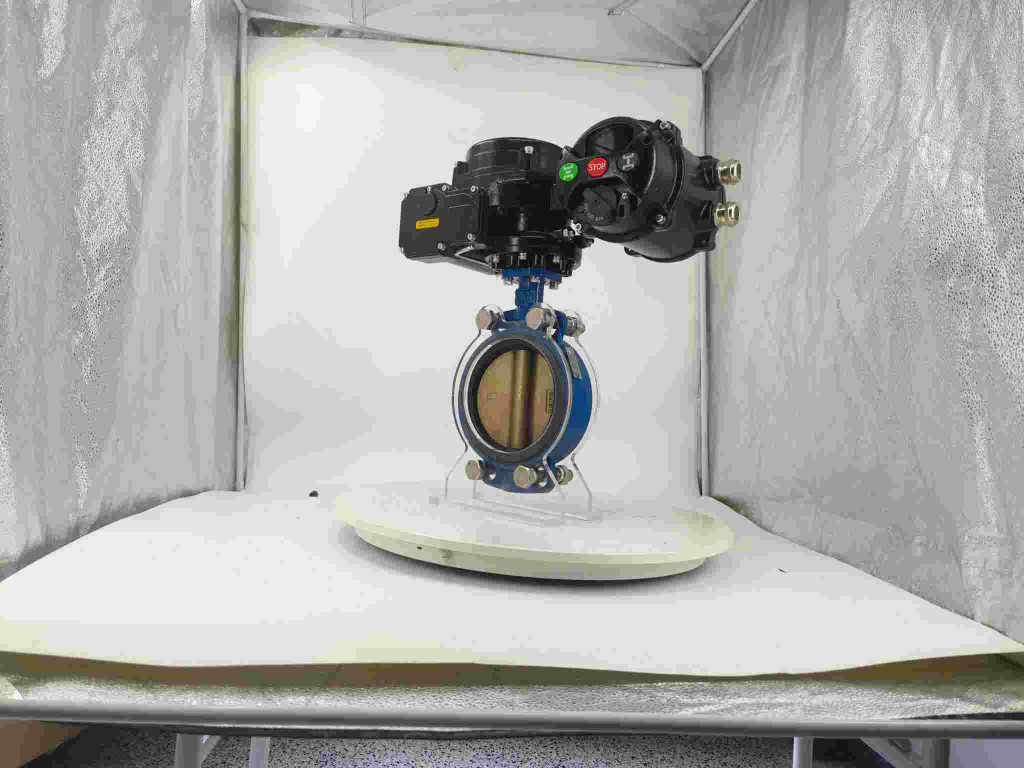

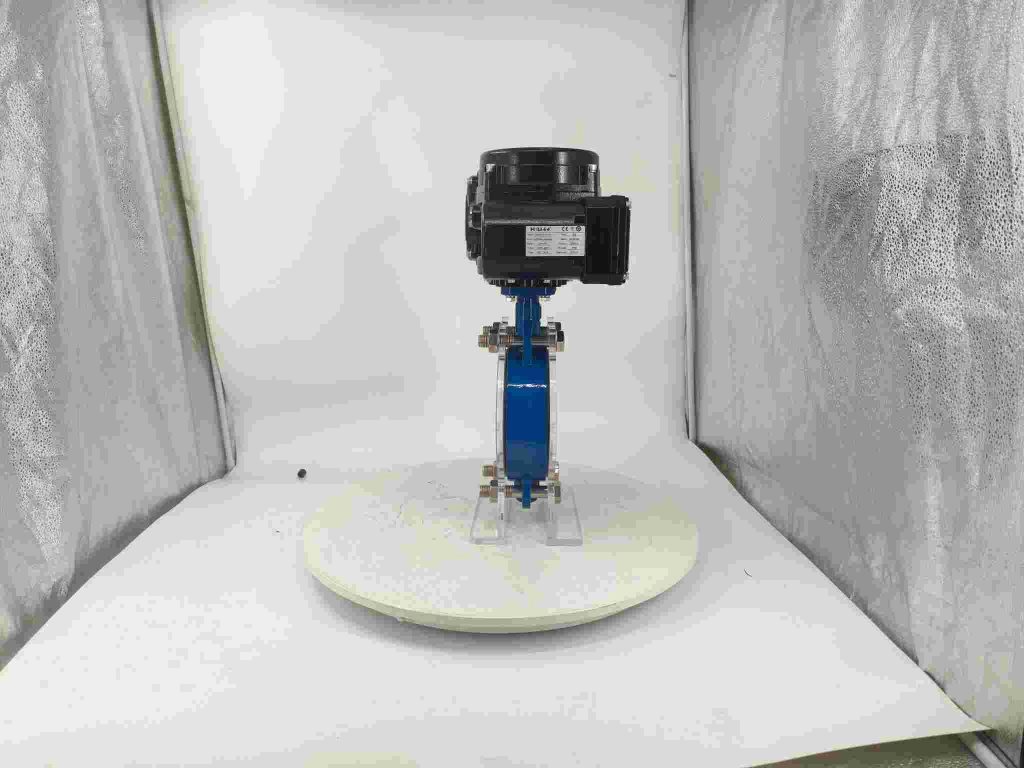

A WCB Electric Ball Valve is an automated valve designed to regulate the flow of liquids and gases through pipelines. The “WCB” refers to the carbon steel material used for the valve body, which offers strength, resistance to wear, and the ability to handle high-pressure and temperature applications. The “electric” component refers to the electric actuator that operates the valve, allowing for automated and precise control. The electric actuator receives signals from control systems and adjusts the valve accordingly, enabling automatic opening and closing or regulating the flow rate of the medium being transported.