In recent years, the adoption of electric vehicles (EVs) has surged, leading to an increasing demand for efficient and rapid charging solutions. One vital component ensuring the effectiveness of rapid charging systems is the Fast Charging Relay. This device plays a crucial role in managing the high power levels involved in charging electric vehicles, ensuring a quick and safe process. In this article, we will delve into the functions, importance, and technological advancements of Fast Charging Relays.

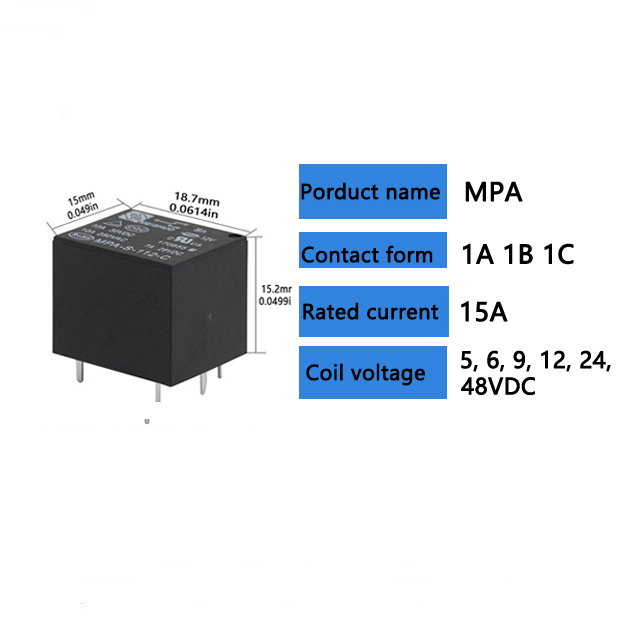

What is a Fast Charging Relay? A Fast Charging Relay is an electromagnetic switch designed to manage the flow of electricity between the charging station and the EV battery. Unlike standard relays, which may handle lower currents and voltages, Fast Charging Relays are engineered to cope with the high voltage (often exceeding 400V) and significant current (up to several hundred amps) involved in rapid charging applications. These relays quickly switch circuits on and off to control the charging process effectively and efficiently. Functions of Fast Charging Relay The primary function of a Fast Charging Relay is to control the on/off status of the power supplied to an electric vehicle’s battery during charging. This control is critical for several reasons: