Relay functional testing is a critical process in verifying the proper operation of relay systems, which are fundamental components in a wide range of automation and control systems. Relays are used to control circuits, protect electrical equipment, and automate processes across various industries, including manufacturing, telecommunications, and transportation. Given their pivotal role, ensuring that relays operate as intended under varying conditions is essential for system reliability and safety. This article discusses the importance of relay functional testing, the key aspects of the testing process, and the methods used to evaluate relay performance.

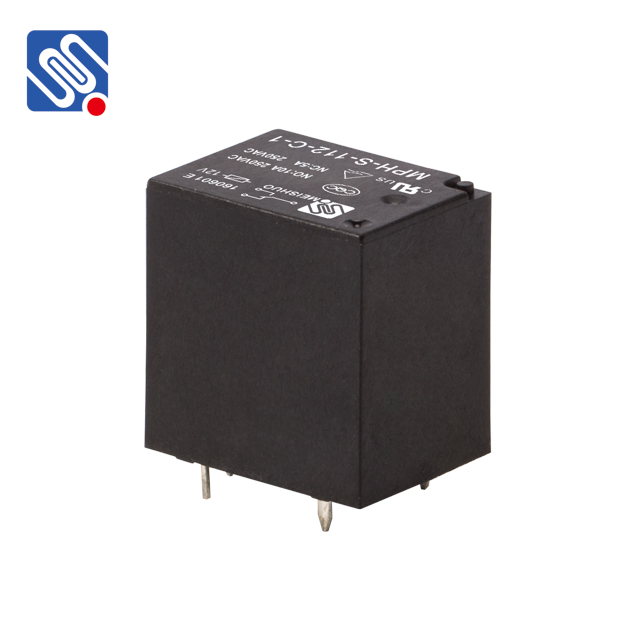

Understanding Relays and Their Role in Automation A relay is an electrically operated switch that opens or closes a circuit in response to a control signal. Typically, relays consist of an electromagnet, a set of contacts, and a spring mechanism. When an electric current flows through the electromagnet, it generates a magnetic field that moves the contacts, either opening or closing the circuit. Relays are widely used in industrial control systems, automotive applications, home automation, and protection systems for electrical equipment. Given the crucial role relays play in controlling and protecting electrical circuits, it is vital to ensure their reliable operation through comprehensive functional testing.