A power relay is an essential electrical component used in various automation and control systems. Its main function is to control the switching of high-power circuits using a low-power signal. Essentially, it acts as an intermediary, allowing smaller electrical signals to control much larger currents, making it indispensable in many industries like electrical power systems, automation, and home appliances. This article explores the working principle of power relays, their types, and their diverse applications.

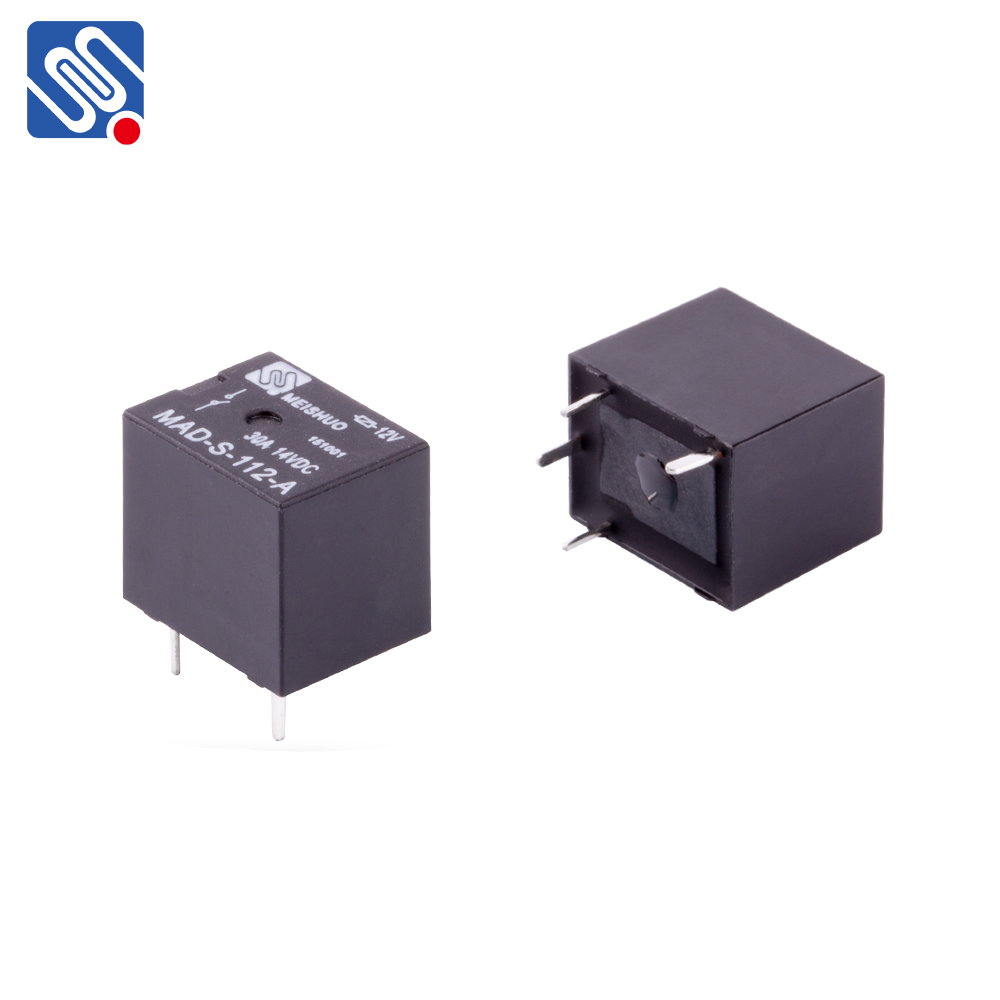

What is a Power Relay? A power relay is an electrically operated switch that opens or closes the contacts of a circuit when energized. It typically consists of a coil, contacts, and a mechanism that is activated when the coil is energized by an electrical current. The relay’s ability to control high-power circuits with a low-power input makes it vital for systems where high voltage or current needs to be controlled, often with limited physical space and lower energy consumption. The relay operates based on the principle of electromagnetic induction. When an electric current flows through the relay’s coil, it generates a magnetic field that moves a mechanical arm or contact that opens or closes the circuit. The power relay can be used to control a variety of devices, ranging from motors and lights to industrial equipment.