In modern engineering and automation, the Flow Control Solenoid Valve plays a critical role in managing fluid dynamics across various systems. These valves are essential components in fluid power systems and automation technology, responsible for regulating the flow of liquids and gases. Their ability to control flow rates and directions efficiently makes them invaluable in diverse applications ranging from industrial machinery to automotive systems.

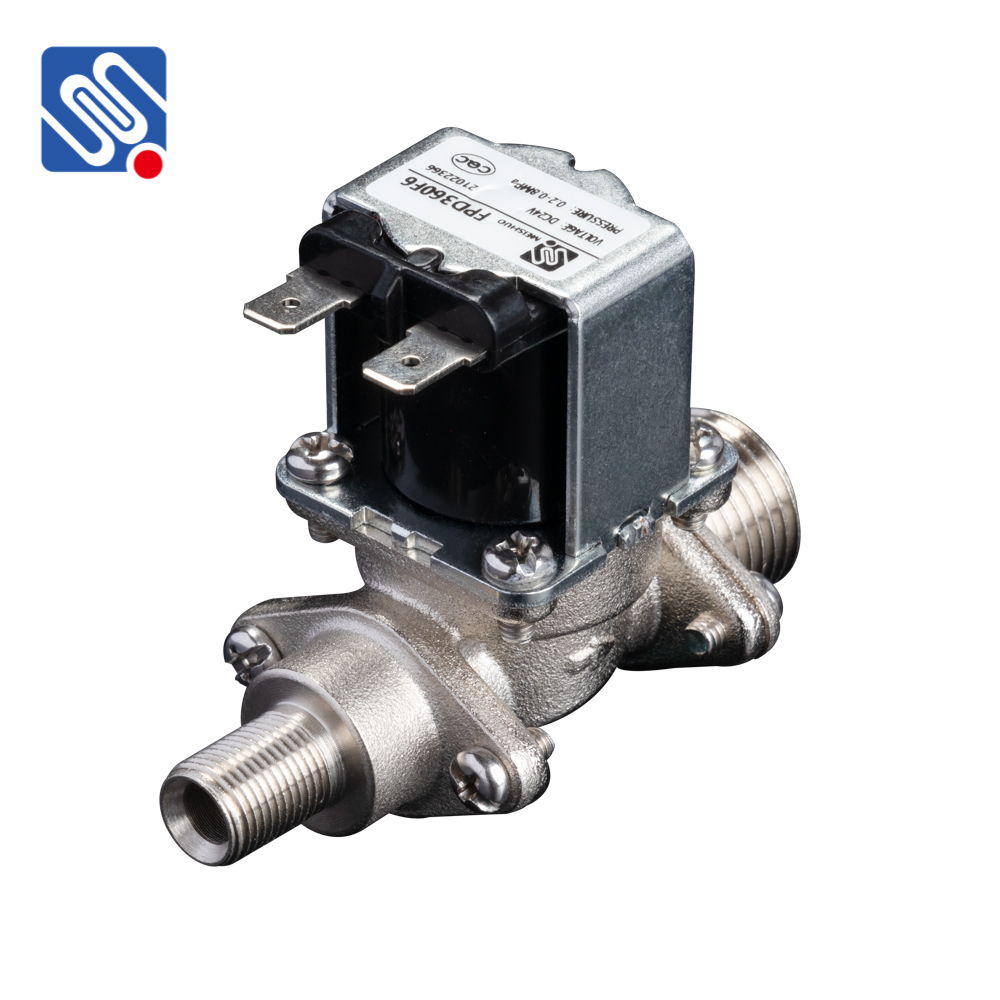

What is a Flow Control Solenoid Valve? A Flow Control Solenoid Valve is an electromechanical device that operates through the interaction of electromagnetic forces and mechanical components. When electrical current flows through a solenoid coil, it generates a magnetic field. This magnetic field moves a plunger or armature that opens or closes the valve, thus controlling the flow of the working fluid. Depending on the design, these valves can either be normally closed (NC) or normally open (NO), offering flexibility in applications. Operating Principles The operational mechanism of a Flow Control Solenoid Valve is relatively straightforward yet highly effective. The valve typically consists of a solenoid coil, a valve body, and an actuator mechanism (usually a plunger). When the coil is energized, the plunger is drawn into the coil, allowing fluid to pass through the valve. Conversely, when the power is turned off, a spring usually returns the plunger to its original position, closing the valve and stopping the fluid flow. This fundamental principle allows for rapid actuation, giving the valve its reputation for quick response times.