Industrial relays are pivotal components in the realm of automation, functioning as electromechanical switches that control the flow of electrical current. They play a crucial role in various applications by enabling small control signals to switch larger loads, thus providing an effective means of powering devices or systems. This article delves into the functions, types, applications, and benefits of industrial relays, showcasing their significance in modern industrial automation.

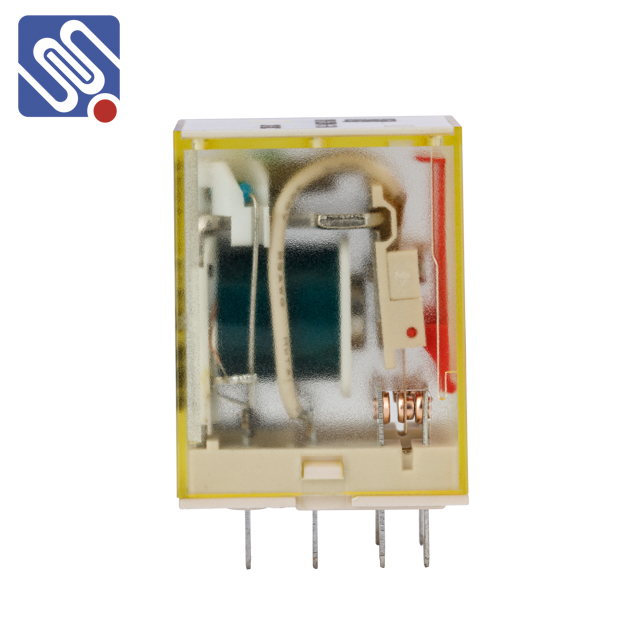

What is an Industrial Relay? At its core, an industrial relay is an electromechanical device that uses an electromagnetic coil to mechanically operate a switch. When electrical current passes through the coil, it generates a magnetic field that attracts an armature, closing or opening the contacts of the switch. This allows the relay to control larger current circuits while being operated by low-power signals. Industrial relays are typically housed in rugged enclosures designed for harsh environments, making them suitable for industrial applications. Types of Industrial Relays Electromechanical Relays (EMR): The most common type, electromechanical relays utilize an electromagnet and movable contacts. These relays are versatile and can be used in various applications, including motor control, lighting control, and alarm systems.