In today’s fast-paced manufacturing landscape, injection molded parts have emerged as indispensable components in various industries. Injection molding is a versatile and efficient process that allows for the creation of intricate and consistent parts with remarkable precision. At the heart of this process are injection molded parts manufacturers, who play a vital role in shaping the modern world of production.

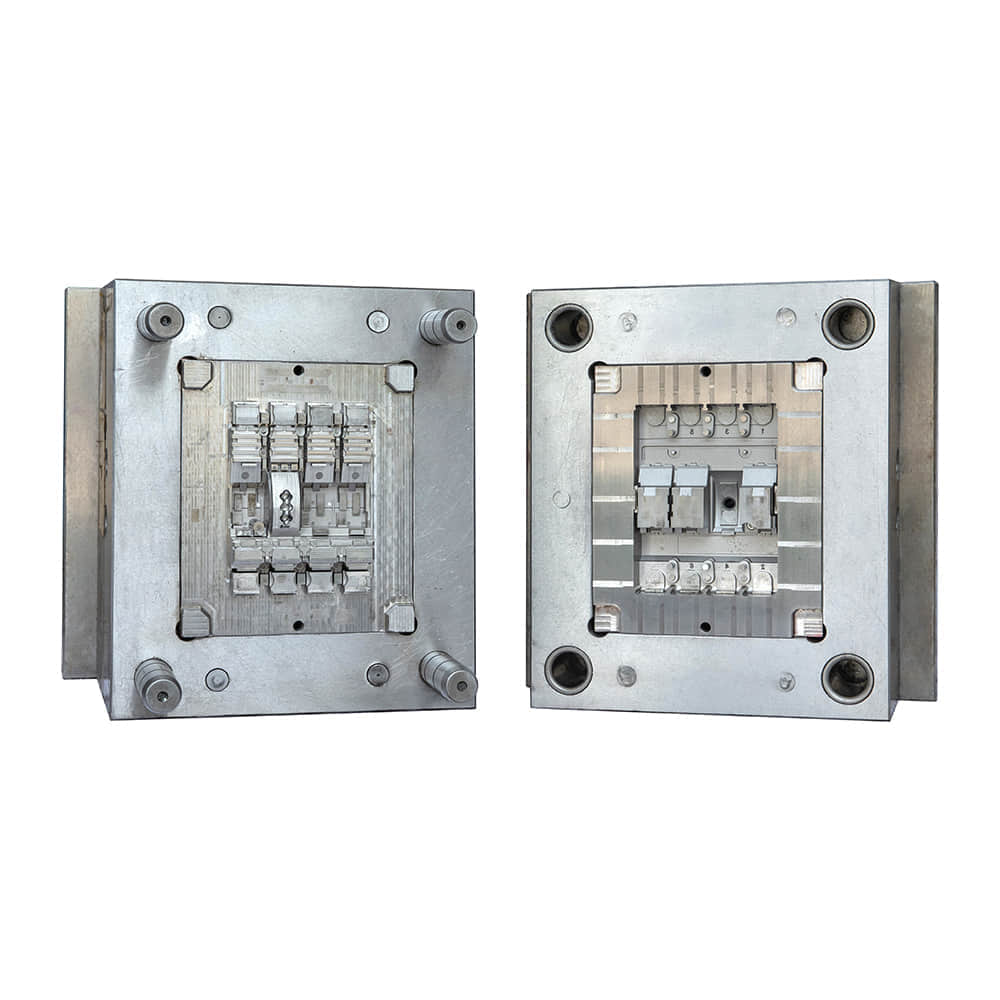

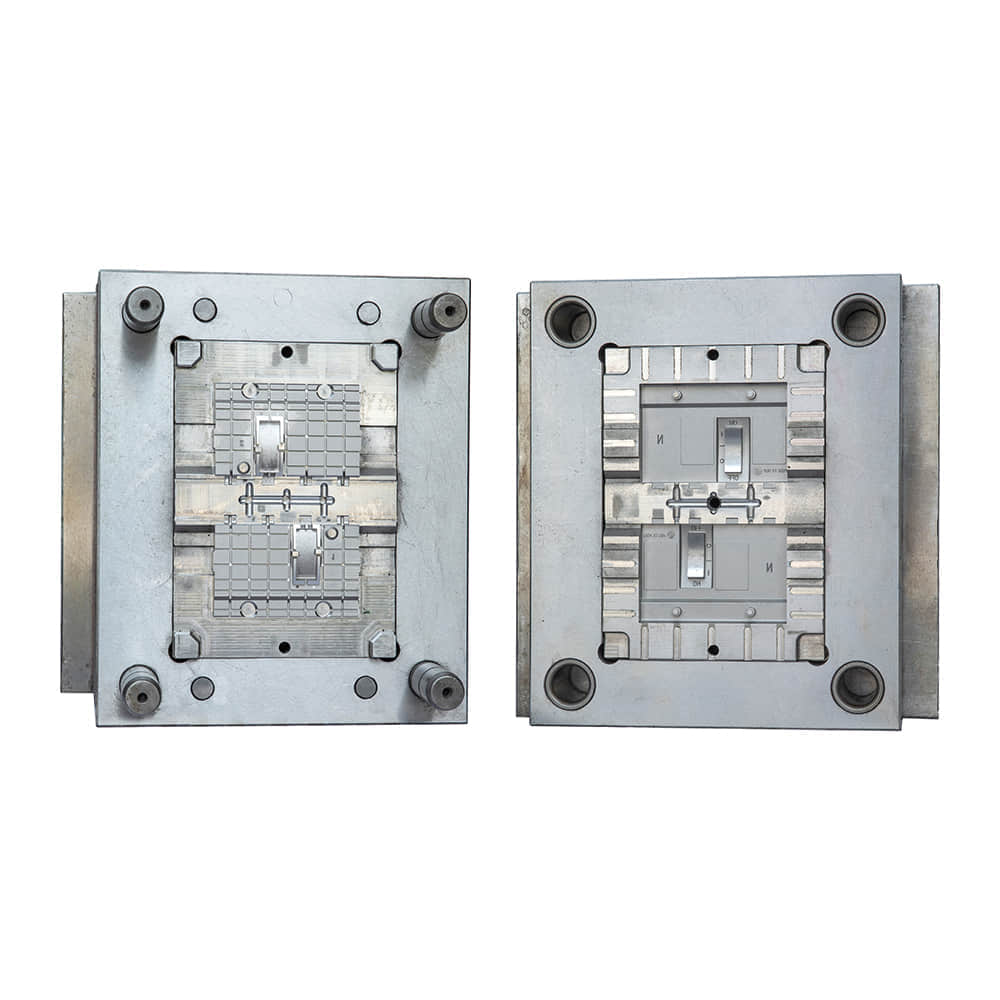

Precision Engineering for Complex Designs

Injection molded parts manufacturers excel in translating complex designs into tangible products. The process begins with the design phase, where engineers work closely with clients to refine and optimize their designs for injection molding. The ability to create highly detailed molds enables manufacturers to produce intricate parts that might be impossible or prohibitively expensive to manufacture through other methods. Materials Mastery One of the key strengths of injection molding is its compatibility with a wide range of materials. Manufacturers can produce parts using various plastics, metals, ceramics, and even hybrid materials. This flexibility allows for the production of parts with diverse characteristics, such as heat resistance, durability, flexibility, and more. Manufacturers’ expertise in selecting the right material for each project is crucial in ensuring the functionality and longevity of the end product. Efficiency and Speed Injection molding is renowned for its efficiency in mass production. Once the molds are designed and created, the actual manufacturing process becomes a streamlined operation. The process involves injecting molten material into the mold cavity, cooling and solidifying it, and then ejecting the finished part. This speed and efficiency not only reduce production time but also minimize material waste, making injection molding a cost-effective choice for high-volume production. Consistency and Quality Consistency is a hallmark of injection molded parts. Manufacturers employ advanced machinery and automation to ensure that each part produced adheres to the same high standard. The automated nature of injection molding minimizes the risk of human error, resulting in products with exceptional quality and uniformity. This reliability is particularly critical in industries where precision and consistency are paramount, such as medical devices, electronics, and automotive components. Innovation and Adaptability The injection molded parts manufacturing industry is far from stagnant. Manufacturers are continuously innovating, incorporating new technologies and techniques to push the boundaries of what is possible. From implementing computer simulations for mold flow analysis to adopting sustainable and eco-friendly materials, these manufacturers are at the forefront of technological advancements, ensuring that they remain relevant and valuable in an ever-evolving market. Customization and Client Collaboration While injection molding excels in mass production, manufacturers also cater to the demand for customized solutions. Modern injection molded parts manufacturers work closely with clients to understand their unique needs and requirements. This collaboration allows for the creation of tailor-made parts that fulfill specific functions and aesthetics, demonstrating the industry’s versatility beyond high-volume production. Conclusion In the realm of modern manufacturing, injection molded parts manufacturers hold a pivotal role. Their expertise in precision engineering, material selection, efficiency, and quality assurance drives innovation across industries. From aerospace to consumer electronics, the products they create have become integral to our daily lives. As technology continues to advance, so too will the capabilities of injection molded parts manufacturers, ushering in a future where the limits of design and production are continually redefined.