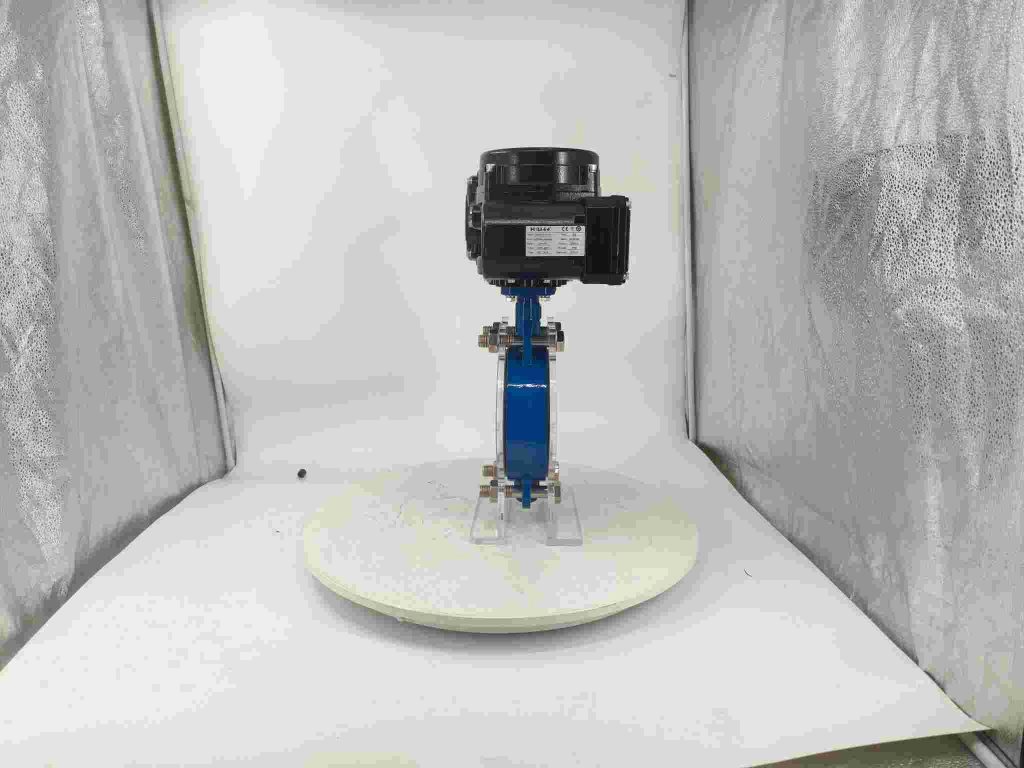

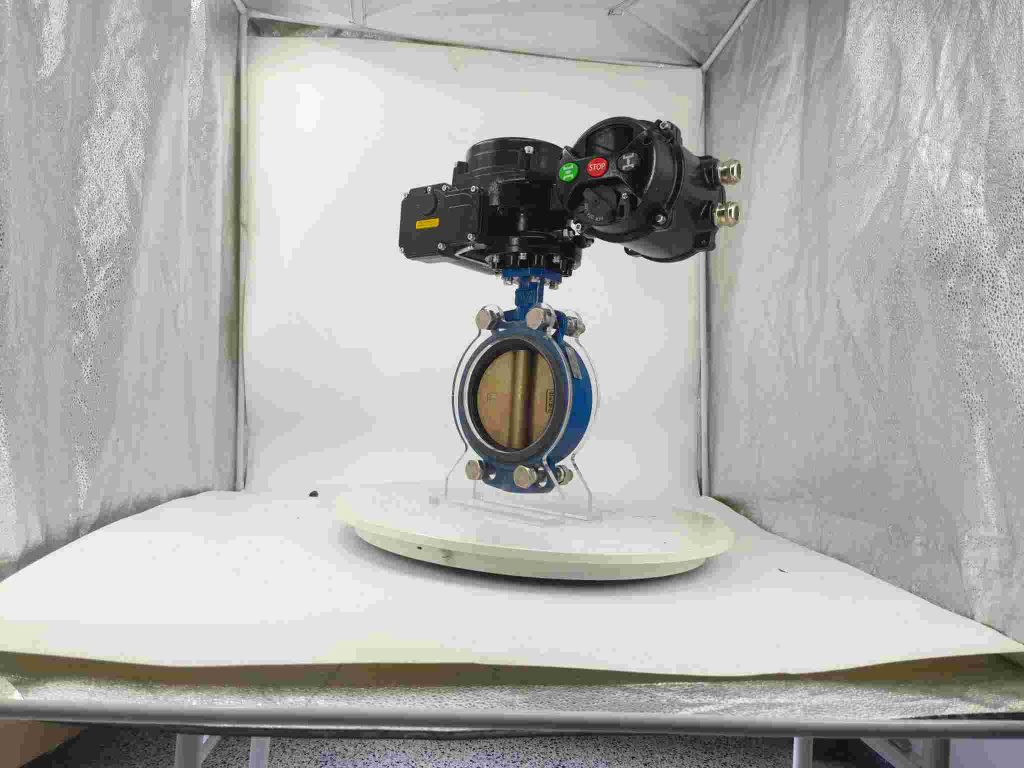

Explosion-proof electric butterfly valves are essential components for controlling fluid flow in hazardous environments where safety and reliability are paramount. These valves, equipped with electric actuators and built to withstand explosive conditions, ensure the secure operation of various industrial systems. In this article, we will explore the role of explosion-proof electric butterfly valve OEM manufacturers, their products, and the industries that rely on these specialized valves for optimal performance.

Understanding Explosion-proof Electric Butterfly Valves

Explosion-proof electric butterfly valves are designed to manage fluid flow while minimizing the risk of ignition in environments containing explosive or flammable materials. These valves are primarily used in industries such as chemical, petrochemical, oil and gas, mining, pharmaceuticals, and other sectors that deal with potentially hazardous substances. The key feature of these valves is their ability to operate without creating sparks or heat that could ignite a volatile atmosphere. A butterfly valve consists of a circular disc that rotates to control the flow of fluid. When electric actuators are added, these valves become automated, offering precise control and remote operation, which is particularly useful in high-risk environments where manual intervention might not be safe. Explosion-proof versions of these valves are specifically designed to prevent any electrical spark or heat from reaching the surrounding area and causing an explosion.