In today’s fast-paced industrial landscape, precision and versatility are two paramount factors that drive innovation and efficiency. Among the numerous techniques employed in manufacturing, injection molding stands as a testament to the perfect blend of these attributes. This article delves into the fascinating realm of injection molded parts manufacturers, shedding light on their significance, processes, and the myriad applications of their products.

The Essence of Injection Molding

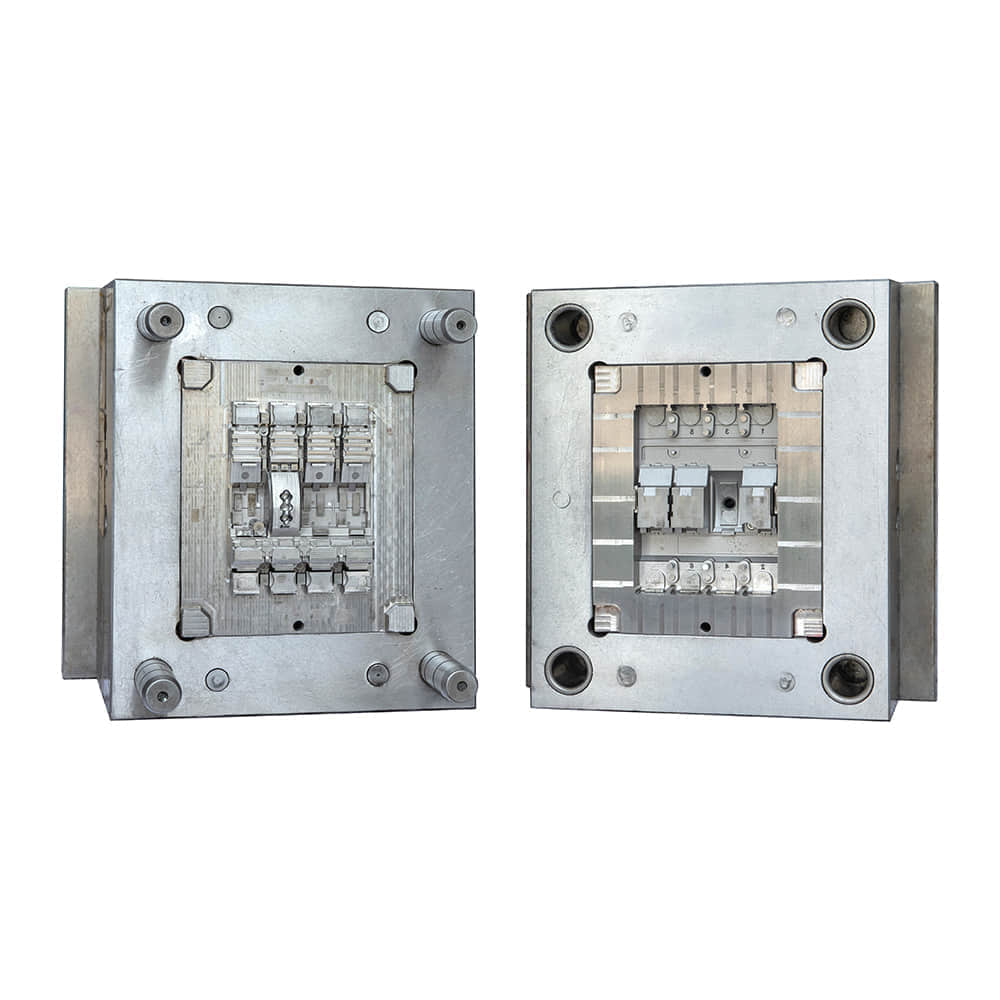

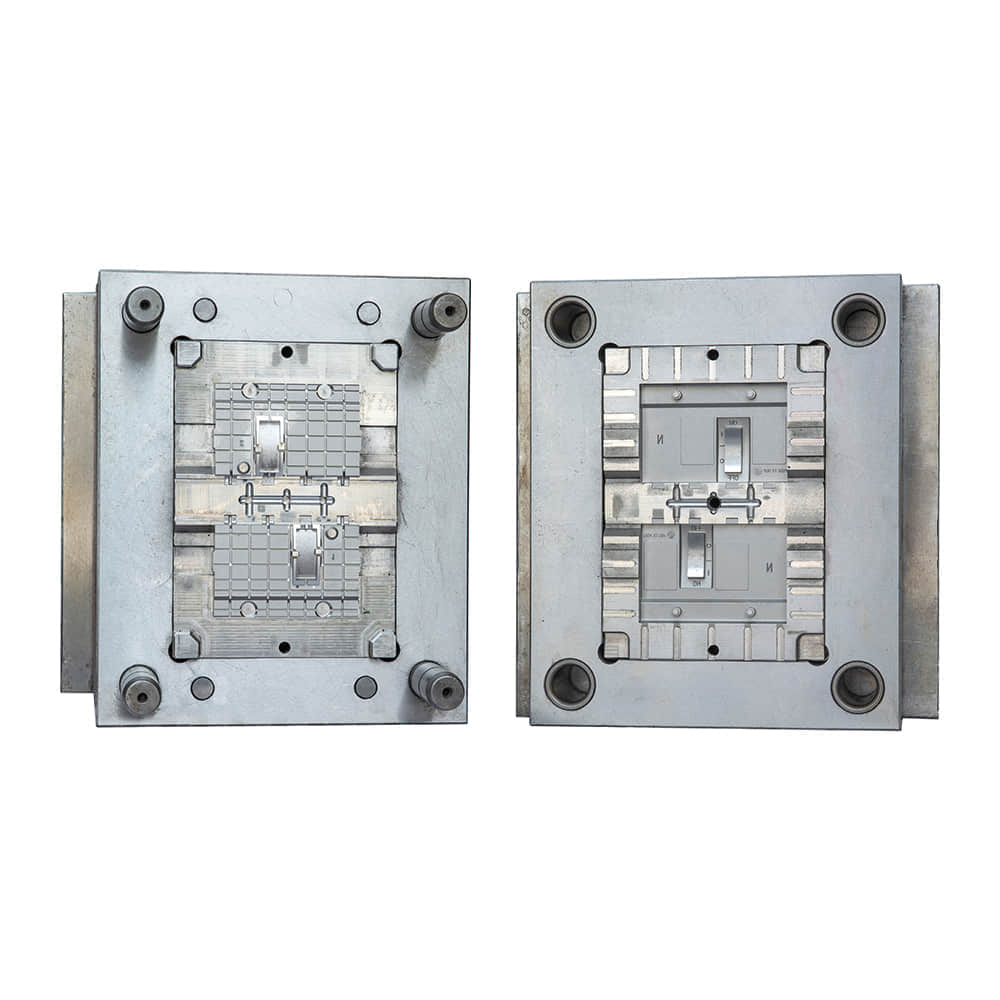

Injection molding is a manufacturing process that involves injecting molten material, usually plastic, into a mold cavity. Once cooled and solidified, this process creates a wide array of intricate and functional parts, ranging from tiny components used in electronics to large automotive parts. The technique has gained immense popularity for several compelling reasons. Precision and Consistency Injection molding offers unrivaled precision and consistency in producing complex shapes with tight tolerances. This precision is a result of the highly controlled and repeatable process, making it ideal for industries where precision is non-negotiable, such as medical devices and aerospace. Cost-Effective Mass Production The ability to produce parts in large quantities with minimal variation is a hallmark of injection molding. It results in cost-effective manufacturing, reducing the per-unit cost as the volume increases. This cost efficiency makes it an attractive choice for mass production in industries like consumer goods and packaging. Material Versatility Injection molding is not limited to a single material. Manufacturers can utilize a wide range of thermoplastics, thermosetting plastics, and even metals. This versatility allows for the production of parts with varying characteristics, from rigid and durable to flexible and lightweight. Design Freedom One of the most significant advantages of injection molding is the freedom it grants in design. Complex geometries, undercuts, and detailed features can be achieved with ease, opening doors to innovative product designs and functionality improvements. Applications Across Industries Injection molded parts manufacturers cater to an extensive array of industries. Here are a few examples: Automotive:From dashboard components to intricate engine parts, the automotive industry heavily relies on injection molding for precision and durability. Medical:In the medical sector, injection molded parts are used in disposable items like syringes and complex instruments such as surgical devices. Consumer Electronics:The sleek and precise exteriors of smartphones and laptops owe much of their aesthetic appeal to injection molding. Packaging:Many of the plastic containers and caps used in the food and beverage industry are created through injection molding. Aerospace:Lightweight and durable components in aircraft and spacecraft are often produced using this method. Quality Assurance and Sustainability Quality control is paramount in injection molding. Manufacturers employ various techniques such as computer-aided design (CAD), computer-aided manufacturing (CAM), and statistical process control (SPC) to ensure consistent quality. Furthermore, there is a growing emphasis on sustainable practices within the industry, including the use of recycled materials and energy-efficient manufacturing processes. The Future of Injection Molded Parts As technology continues to advance, so does the injection molding industry. 3D printing and digital manufacturing techniques are being integrated into injection molding processes to enhance efficiency and reduce lead times. Additionally, the development of bio-based and biodegradable materials is poised to make injection molding even more environmentally friendly. In conclusion, injection molded parts manufacturers play a pivotal role in modern manufacturing. Their ability to provide precision, versatility, and cost-effectiveness has made them indispensable across various industries. With ongoing advancements in materials and processes, the future of injection molding promises even greater innovation and sustainability. These manufacturers are not just shaping products; they are shaping the future of manufacturing itself.