Introduction

Injection molding has revolutionized the manufacturing industry, enabling the production of intricate and precise parts with remarkable efficiency. This article delves into the world of injection molded parts, exploring their manufacturing process, advantages, diverse applications, and the future trends shaping this innovative field.

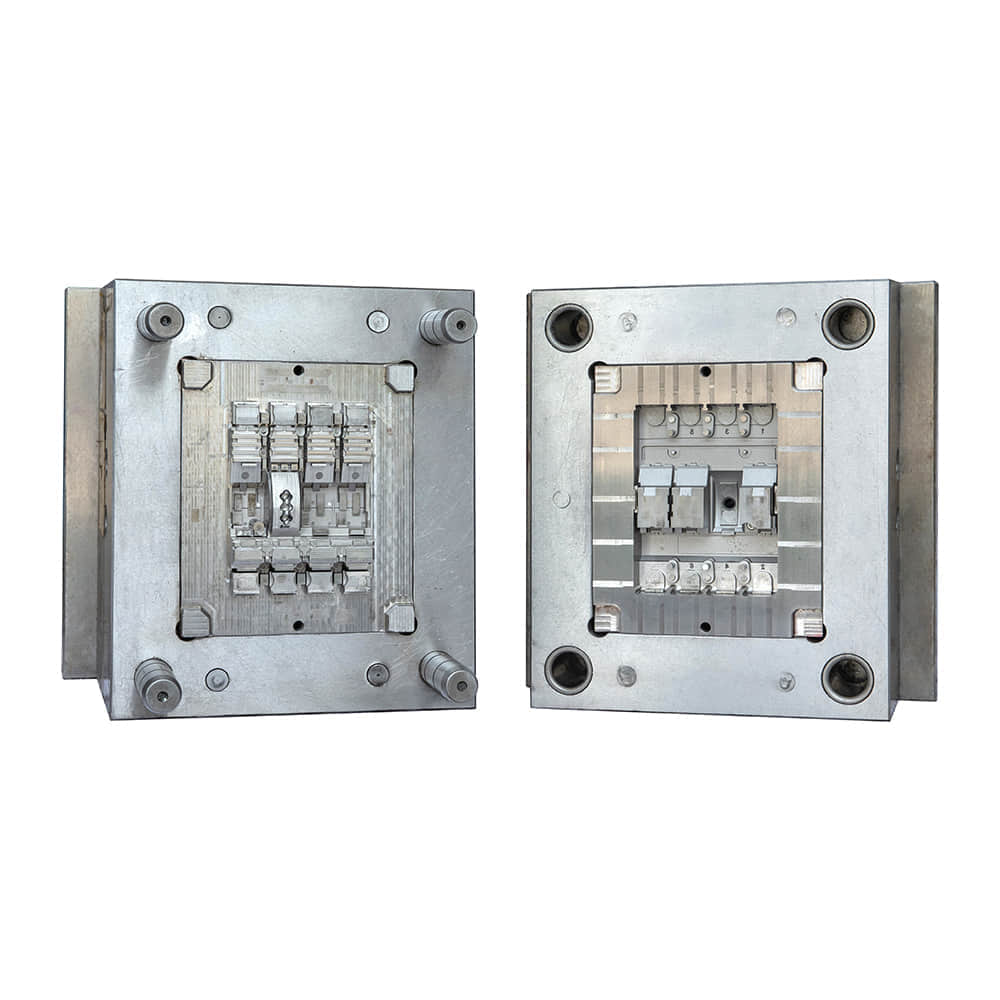

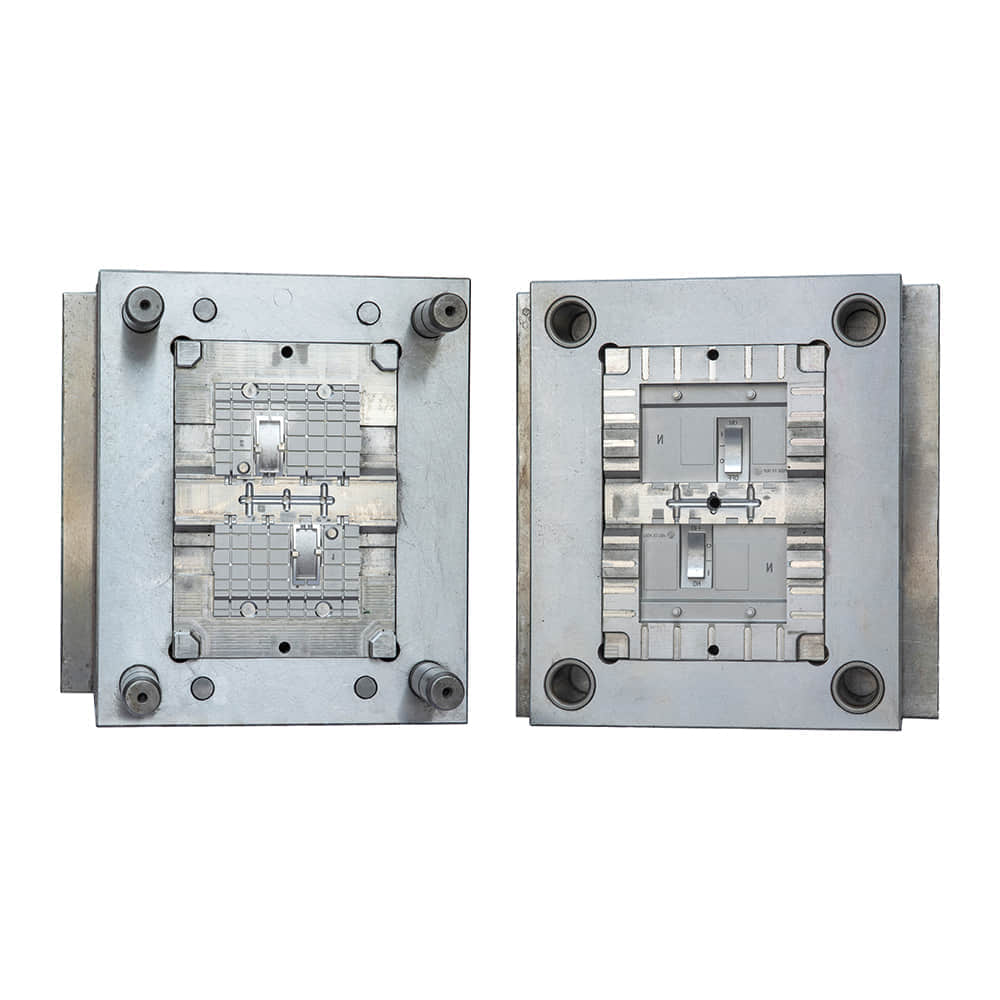

The Injection Molding Process Injection molding is a versatile manufacturing technique that involves injecting molten material, usually plastic, into a mold cavity to create intricate shapes and structures. The process begins with the selection of suitable materials, which are then melted and injected into a mold using high-pressure machinery. Once the material cools and solidifies within the mold, the finished part is ejected, ready for use. Advantages of Injection Molded Parts Precision and Complexity: Injection molding allows for the creation of intricate and complex designs with exceptional precision. This level of detail is hard to achieve with other manufacturing methods. Cost-Efficiency: Mass production is a strong suit of injection molding. Once the initial mold is created, producing additional parts becomes more cost-effective, making it ideal for large-scale manufacturing. Material Variety: A wide range of materials, including various plastics and polymers, can be used in injection molding. This flexibility makes it suitable for diverse applications across industries. Speed: The cycle time for producing injection molded parts is relatively short, leading to quick production turnaround times. Applications of Injection Molded Parts Automotive Industry: Injection molded parts find extensive use in the automotive sector, from interior components like dashboards and panels to critical under-the-hood parts due to their durability and cost-effectiveness. Consumer Electronics: The precision and high-quality surface finish of injection molded parts make them an excellent choice for producing components in consumer electronics, such as phone cases, connectors, and buttons. Medical Devices: In the medical field, where precision and cleanliness are paramount, injection molding produces components for devices like syringes, valves, and casings for various medical equipment. Packaging Industry: Many packaging solutions rely on injection molded parts, as they can be customized to fit specific shapes and sizes, offering both functionality and branding opportunities. Toys and Novelties: Injection molding is the technology behind the production of a multitude of toys, providing a cost-effective way to create intricate designs that are safe and durable. Aerospace Sector: The aerospace industry benefits from injection molded parts for lightweight components that maintain structural integrity under the demanding conditions of flight. Future Trends in Injection Molding Advanced Materials: The development of new materials, such as biodegradable plastics and composites, will expand the range of applications for injection molded parts. Additive Manufacturing Integration: Injection molding combined with additive manufacturing techniques could lead to hybrid processes that offer even greater design freedom and efficiency. Industry 4.0 Integration: Injection molding machinery is becoming more interconnected, enabling real-time monitoring and optimization of the production process, leading to improved quality control. Sustainability: As environmental concerns grow, the industry is likely to focus on more sustainable practices, including recycling of materials and reducing energy consumption. Conclusion Injection molded parts have redefined modern manufacturing by offering precision, cost-efficiency, and versatility across various industries. From automotive components to medical devices, their applications are vast and continue to expand. With ongoing advancements in materials, technology, and sustainability, injection molding remains a driving force in shaping the future of production and design.