In today’s dynamic manufacturing landscape, injection mold manufacturers play a crucial role in bringing innovation and efficiency to various industries. With their expertise in designing and producing molds used for creating intricate and precise parts, these manufacturers enable the mass production of a wide range of products that we use in our daily lives. This article explores the significance of injection mold manufacturers and their impact on the modern manufacturing industry.

Precision Engineering: The Foundation of Injection Mold Manufacturing

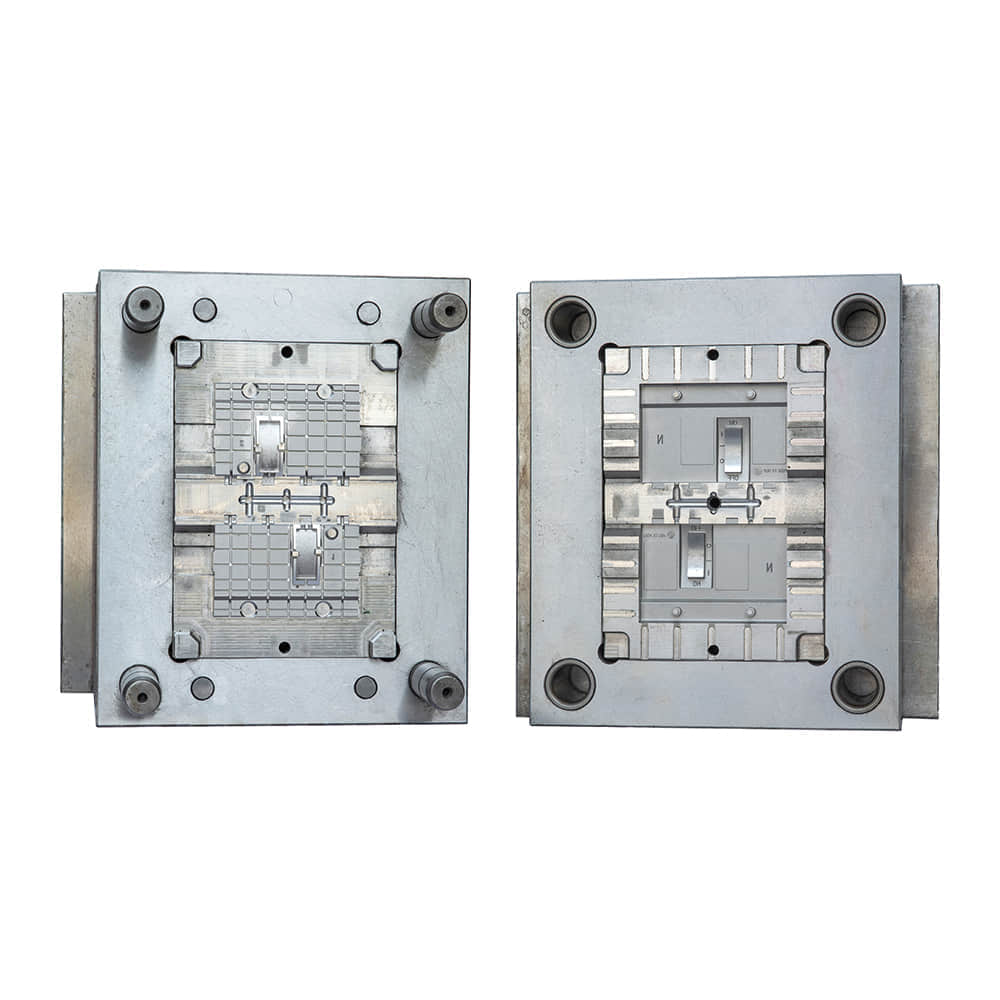

Injection mold manufacturers specialize in precision engineering. They meticulously design molds to create products with intricate details and exact specifications. Whether it’s the housing of your smartphone, the components of a medical device, or the interior parts of an automobile, injection molds enable the production of parts that fit together seamlessly, ensuring the final product’s quality and functionality. Driving Innovation Through Customization Innovation in product design often demands custom-made parts. Injection mold manufacturers contribute to this process by producing molds tailored to the specific needs of a project. This level of customization allows product designers and engineers to push the boundaries of what’s possible, giving rise to groundbreaking designs and technological advancements. As industries continue to evolve, injection mold manufacturers provide the foundation upon which innovation thrives. Efficiency and Cost-Effectiveness Injection molding is a highly efficient and cost-effective method of producing parts in large quantities. The molds can be used repeatedly, and each injection cycle produces multiple parts. This rapid production cycle, coupled with the ability to produce intricate designs in one piece, significantly reduces the need for additional assembly or post-processing. This efficiency not only speeds up production but also reduces costs, making injection molding a preferred choice for manufacturers worldwide. Quality Assurance and Material Expertise The quality of the final product depends on the precision of the mold and the materials used in the injection process. Injection mold manufacturers possess a deep understanding of different materials—such as plastics, metals, and composites—ensuring that the chosen material suits the intended application. Additionally, these manufacturers implement rigorous quality control processes to identify and rectify any defects in the molds, resulting in consistent, high-quality parts. Environmental Considerations In recent years, sustainability has become a paramount concern across industries. Injection mold manufacturers are responding to this challenge by exploring eco-friendly materials and production methods. By adopting biodegradable or recycled materials and optimizing production processes to minimize waste, these manufacturers contribute to reducing the environmental impact of modern manufacturing. Collaborative Partnerships in Manufacturing Injection mold manufacturers don’t operate in isolation. They often work closely with product designers, engineers, and manufacturers to ensure that the mold design aligns with the intended product and production process. This collaboration streamlines the entire manufacturing chain, from concept to final product, resulting in a faster time-to-market and improved overall product quality. Conclusion The role of injection mold manufacturers in the modern manufacturing industry is indispensable. Their precision engineering, commitment to innovation, and dedication to efficiency and quality make them vital contributors to a wide range of sectors. As technology advances and industries continue to evolve, injection mold manufacturers will remain at the forefront of driving progress, enabling the creation of products that shape our world.