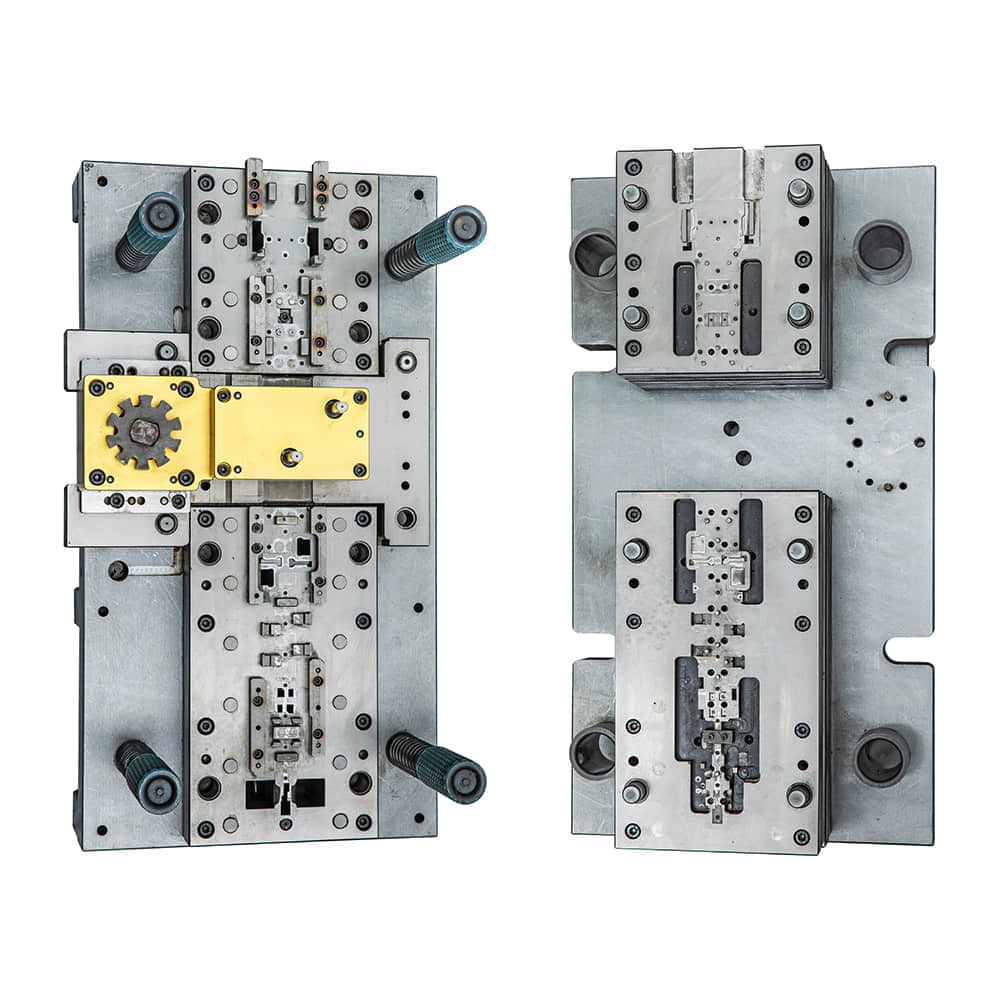

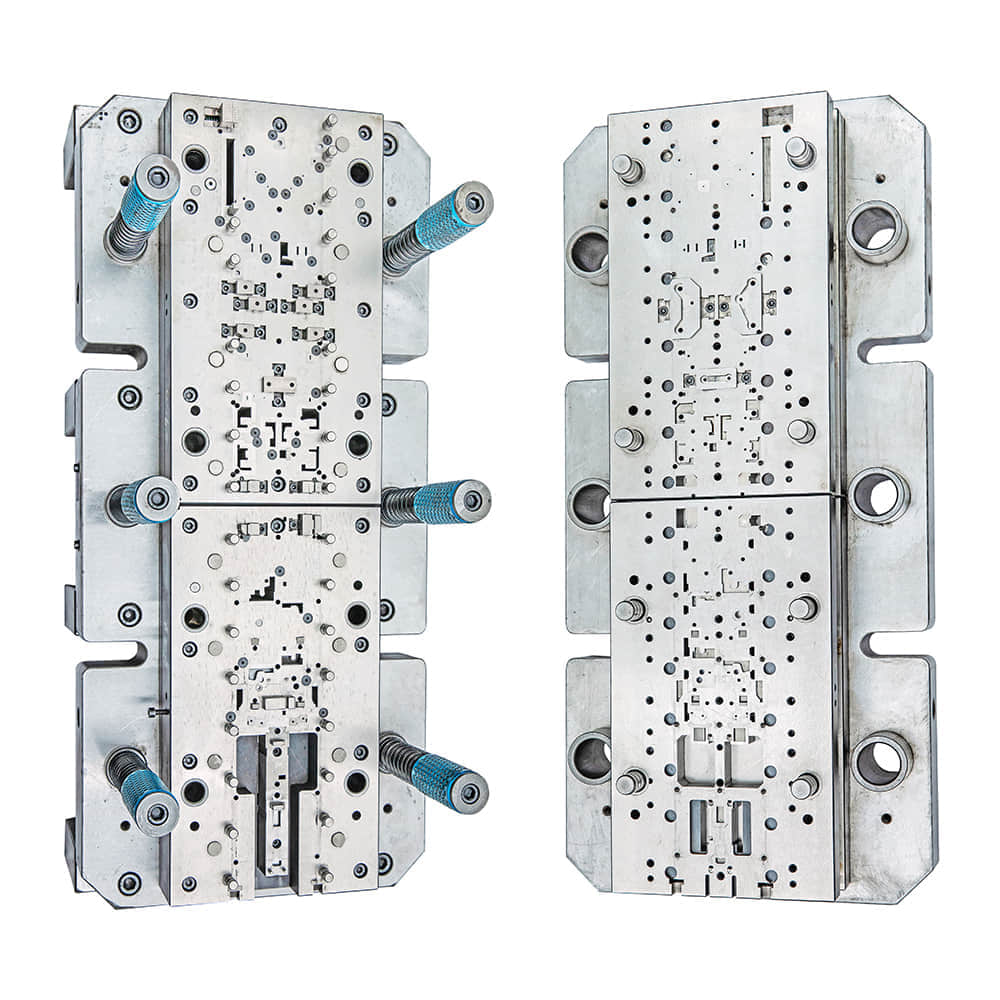

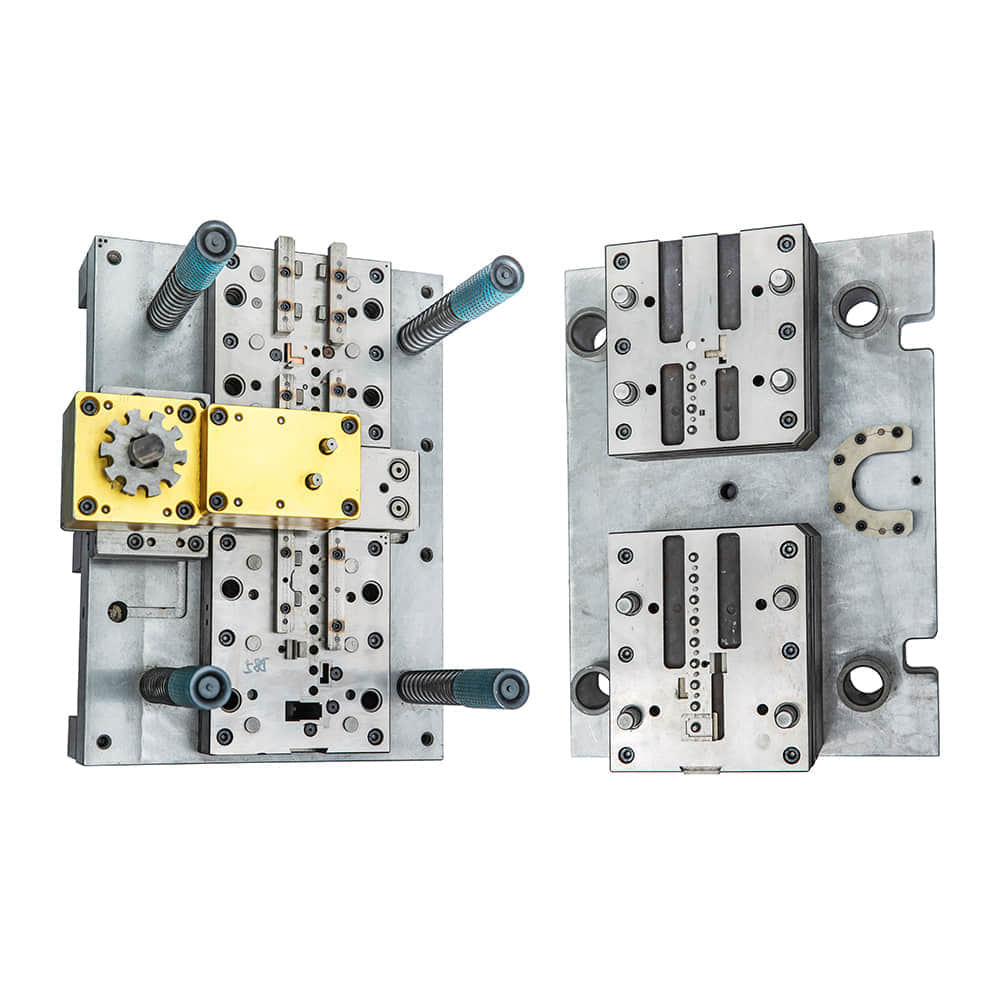

In the heart of China’s thriving manufacturing landscape, there exists a dynamic force that powers industries worldwide – China Hardware Mold Manufacturers. These unsung heroes play a pivotal role in the production of everything from consumer electronics to automotive components, utilizing cutting-edge technology and a commitment to precision that defines the future of manufacturing.

The Backbone of Innovation

China’s hardware mold manufacturers are the backbone of innovation, providing the molds that shape the products we use every day. These manufacturers have not only embraced advanced technologies but have also pioneered them. They blend traditional craftsmanship with modern CNC machining and 3D printing techniques, ensuring that their molds are of the highest quality and precision. Global Reach, Local Excellence What sets China Hardware Mold Manufacturers apart is their global reach. While based in China, their products find homes in industries across the world. This international perspective pushes them to maintain the highest standards in the industry, ensuring their molds meet the exacting specifications of global clients. Diverse Applications From the aerospace sector to medical devices, the products of China’s hardware mold manufacturers have a diverse range of applications. They create molds for intricate surgical instruments with the same expertise and precision as those designed for automotive components. This adaptability showcases their ability to cater to the unique demands of various industries. Continuous Innovation Innovation is a driving force for China’s hardware mold manufacturers. They invest heavily in research and development, always looking for ways to improve their molds, reduce production times, and minimize waste. This commitment to innovation not only benefits their clients but also contributes to the sustainability of manufacturing processes. Quality Control Quality control is paramount in the world of mold manufacturing. China’s hardware mold manufacturers implement stringent quality control processes to ensure that each mold meets the highest standards. They utilize state-of-the-art testing equipment, conduct rigorous inspections, and employ skilled technicians who are experts in identifying even the most minute imperfections. Environmental Responsibility China’s hardware mold manufacturers are acutely aware of their environmental responsibilities. They strive to minimize waste, reduce energy consumption, and implement sustainable practices in their operations. By doing so, they play a role in mitigating the environmental impact of the manufacturing industry. Global Partnerships Collaboration is key to the success of China’s hardware mold manufacturers. They work closely with clients, often forming long-term partnerships that allow for better understanding of each project’s unique requirements. This collaborative approach ensures that the molds produced are not just pieces of metal but vital components in the realization of innovative products. The Future Beckons As industries around the world continue to evolve, China Hardware Mold Manufacturers remain at the forefront of this transformation. Their dedication to precision, innovation, and sustainability ensures that they will continue to be instrumental in shaping the products and technologies of the future. In conclusion, China’s hardware mold manufacturers are the unsung heroes of the manufacturing world. They provide the essential molds that enable the creation of countless products, from the mundane to the cutting-edge. Their commitment to quality, innovation, and environmental responsibility makes them a cornerstone of global industry, and their influence is set to grow as we march toward an ever-more innovative and interconnected future.