A one way solenoid valve is an essential component used in various industrial systems to control the direction of fluid flow. This type of valve ensures that the fluid can only flow in one direction, preventing backflow and ensuring system efficiency and safety. One way solenoid valves are commonly found in pneumatic, hydraulic, and fluid control systems, and they play a significant role in both automation and everyday industrial applications. This article delves into the functionality, uses, and benefits of these valves, exploring why they are integral to modern systems.

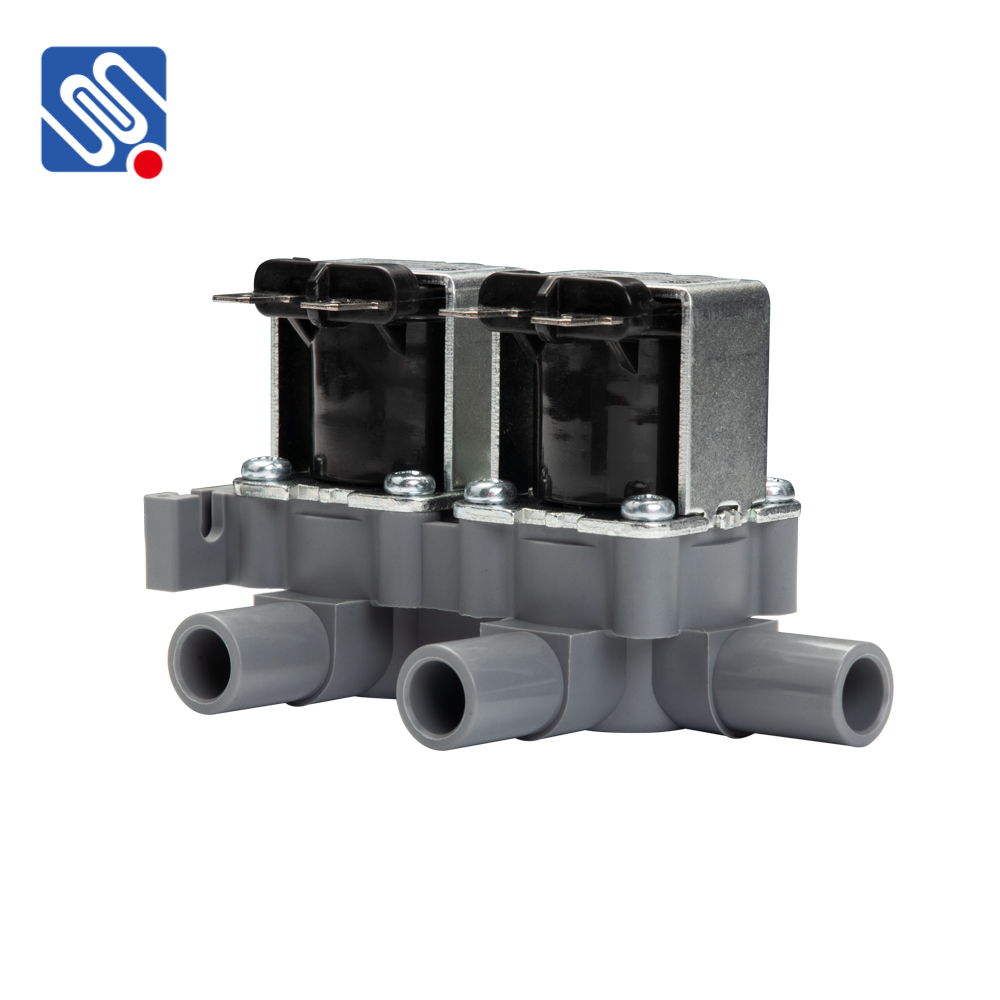

What is a One Way Solenoid Valve? A one way solenoid valve, also known as a check valve or directional control valve, is an electromechanical device that regulates the flow of gases, liquids, or steam in a system. The valve is designed to allow flow in only one direction and automatically blocks the flow in the opposite direction. The operation of this valve is controlled by an electric current, which activates a solenoid to move the valve mechanism and open or close the flow path. The key components of a one way solenoid valve include the solenoid coil, a plunger or armature, and a spring. When an electric current is applied to the coil, it generates a magnetic field that moves the plunger. This movement either opens or closes the valve, depending on the design. When there is no electrical current, the valve typically remains in its default position (either open or closed), ensuring the system operates correctly.