Solenoid valves are electromechanical devices that control the flow of liquids and gases in a variety of systems. These valves use an electromagnetic coil to control the opening and closing of a valve, which regulates fluid flow. Solenoid valves are widely used across industries for their reliability, efficiency, and ability to automate fluid control systems. Among the different materials used to manufacture solenoid valves, Stainless Steel and Plastic Solenoid Valves are two of the most popular choices. Each type of valve offers distinct advantages based on the specific needs of an application, such as chemical resistance, temperature tolerance, and cost-effectiveness.

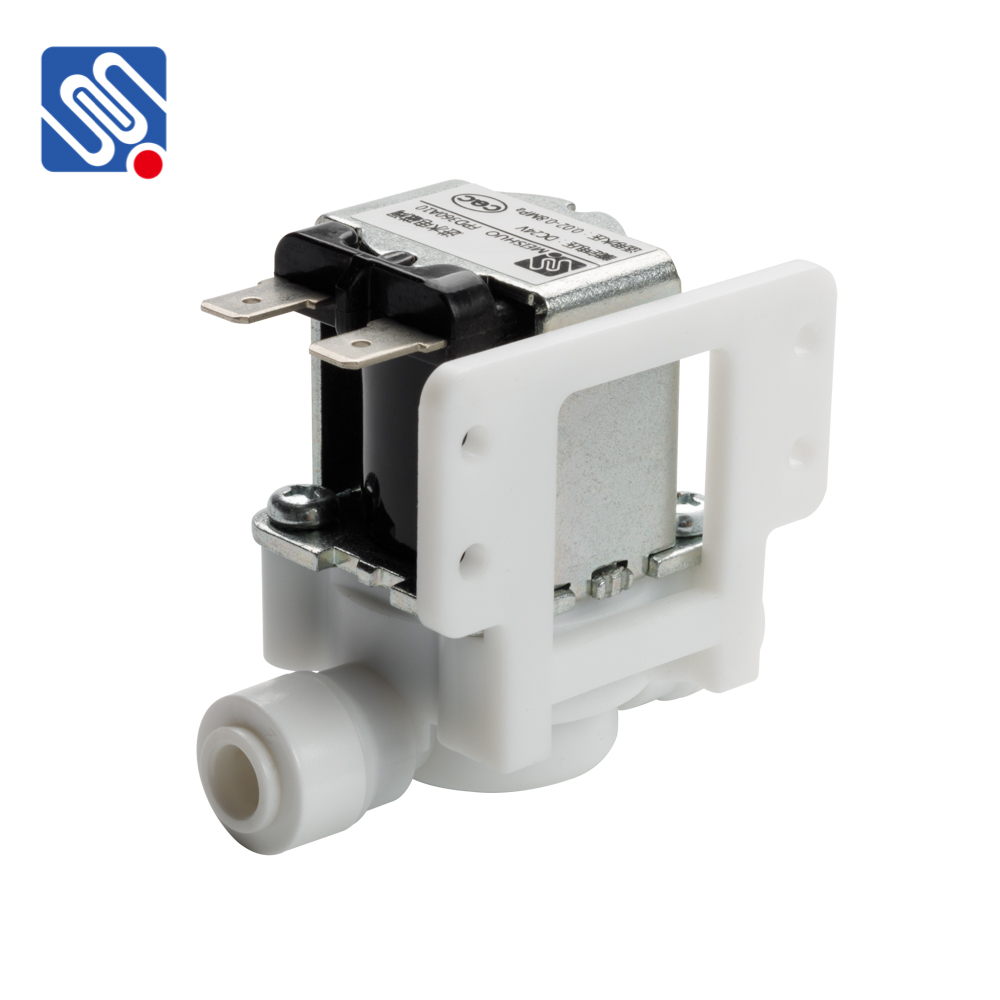

Understanding Solenoid Valves At its core, a solenoid valve consists of a coil, a plunger, and a valve seat. When electrical current passes through the coil, it creates a magnetic field that moves the plunger, either opening or closing the valve. This allows the solenoid valve to control fluid flow, whether it’s in a simple on/off operation or in more complex flow regulation. Stainless Steel Solenoid Valves Stainless Steel Solenoid Valves are known for their durability, high pressure resistance, and excellent performance in extreme environments. Stainless steel is one of the most commonly used materials in solenoid valves because of its exceptional strength and resistance to corrosion and rust. These valves are particularly suited for applications involving aggressive fluids or gases, including acids, bases, and other corrosive chemicals.