Progressive Die: Revolutionizing Manufacturing Processes

In today’s rapidly evolving industrial landscape, innovation is the driving force behind the quest for increased efficiency, productivity, and cost-effectiveness. One remarkable innovation that has left an indelible mark on the manufacturing industry is the progressive die. This remarkable tool has revolutionized the way we produce a wide array of products, from automotive components to consumer electronics. In this article, we will delve into the world of progressive dies, exploring their design, applications, advantages, and the significant impact they have had on modern manufacturing.

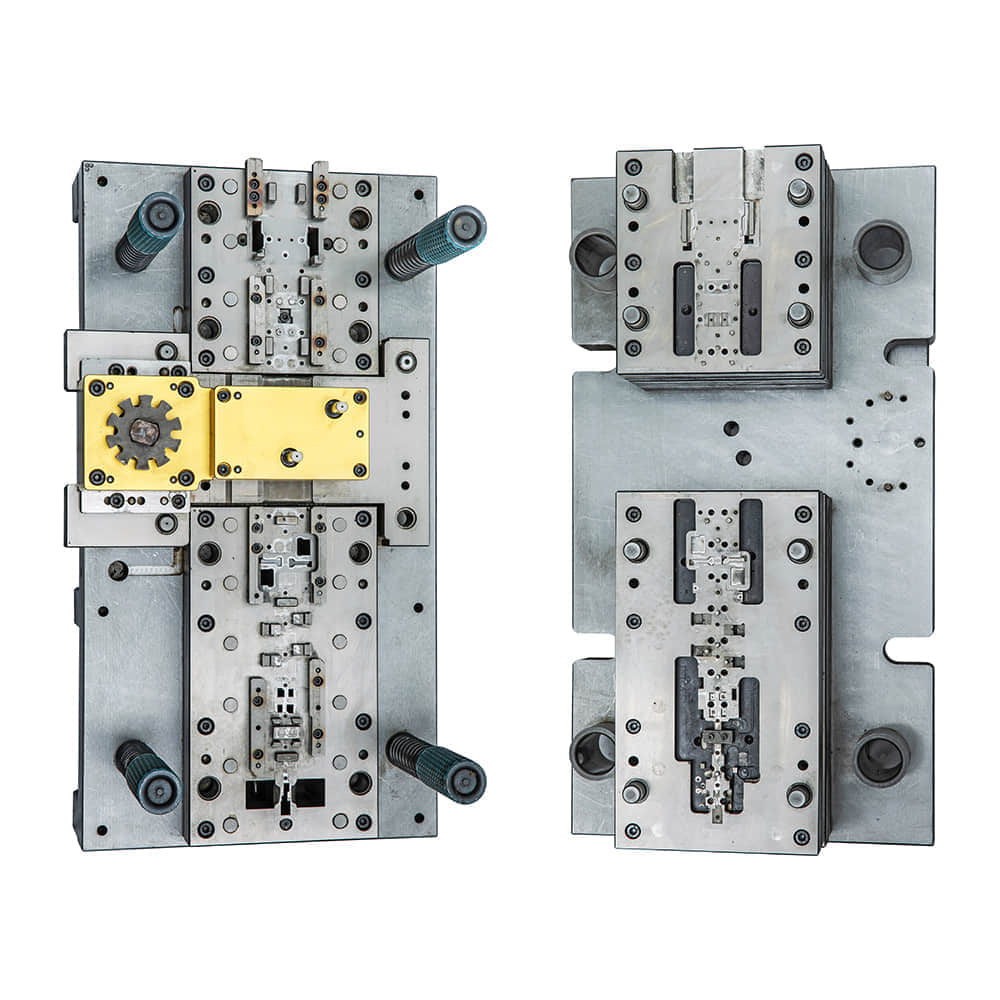

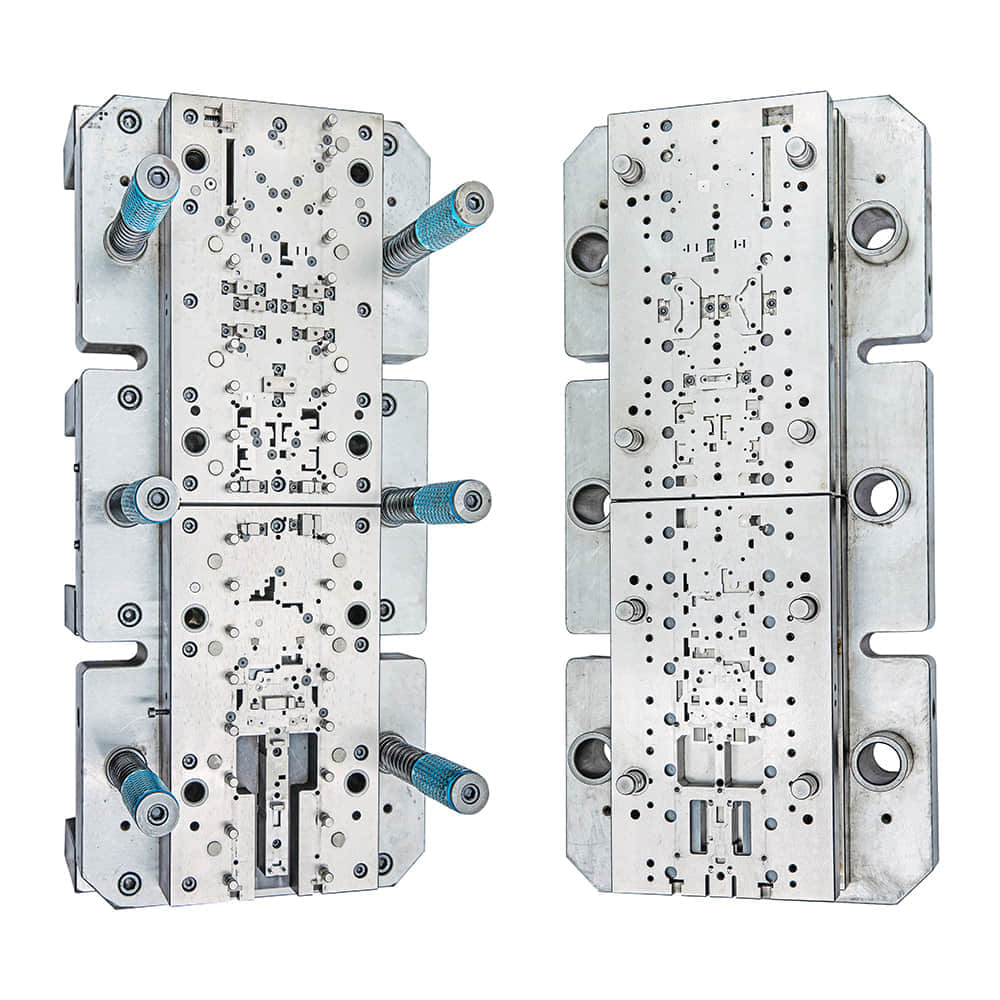

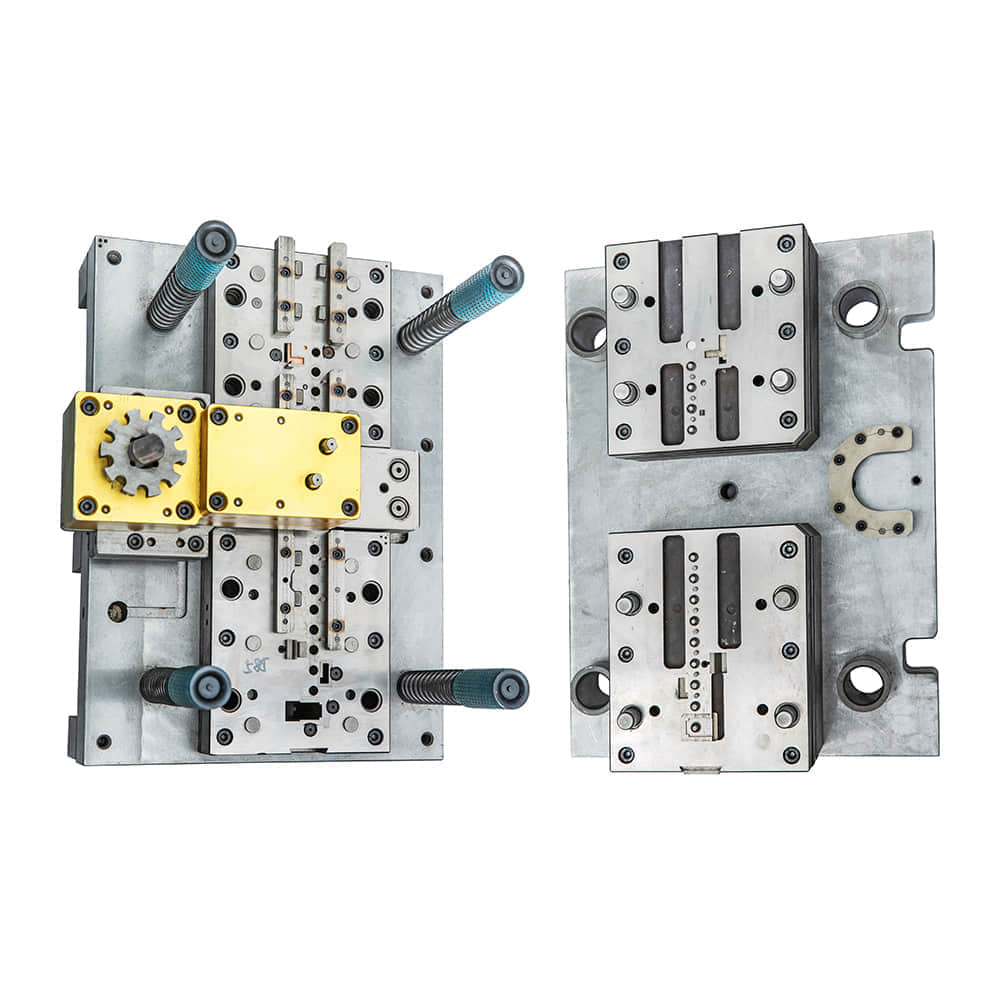

The Anatomy of a Progressive Die At its core, a progressive die is a specialized tool used in the metalworking industry to stamp, cut, or shape metal sheets into specific forms. Unlike traditional single-station dies, progressive dies consist of a series of workstations, each designed to perform a different operation on the metal sheet as it moves through the die. These workstations are meticulously engineered and precisely coordinated to ensure seamless production. A typical progressive die consists of the following key components: Die Plate: The die plate serves as the foundation for the entire tool. It is a sturdy, flat surface upon which all the other components are mounted. Punches: These are sharp, specially shaped components that exert force on the metal sheet to create holes, cut shapes, or form contours. Strippers: Strippers help remove the finished parts from the punch after each operation, preventing the metal from sticking to the punch. Guides and Pilots: These components ensure that the metal sheet is properly aligned as it moves through the die, maintaining accuracy and precision. Progressive Die Stations: Each station within the die is responsible for a specific operation, such as piercing, bending, or forming. The metal sheet advances from one station to the next as each operation is completed. Applications of Progressive Dies Progressive dies are incredibly versatile and find applications in a wide range of industries, including automotive, electronics, aerospace, and more. Some common products produced with progressive dies include: Automotive Parts: Progressive dies are used to create various automotive components, including body panels, brackets, and connectors. Electrical Components: They are employed to manufacture intricate components for consumer electronics, such as connectors, pins, and housings. Appliances: Progressive dies are used to produce parts for household appliances like washing machines, refrigerators, and ovens. Fasteners: They play a crucial role in creating fasteners like screws, bolts, and rivets, which are essential in construction and manufacturing. Advantages of Progressive Dies The adoption of progressive dies offers several significant advantages to manufacturers: High Efficiency: Progressive dies enable continuous, high-speed production, reducing cycle times and increasing output. Accuracy and Consistency: The precise design of progressive dies ensures that each part produced is identical in size and shape, minimizing variations and defects. Cost Savings: Reduced material waste, lower labor costs, and increased production rates contribute to significant cost savings over time. Versatility: Progressive dies can be easily reconfigured or modified to produce different parts, making them adaptable to changing production needs. Quality Control: Progressive dies allow for better quality control and inspection during the production process, reducing the likelihood of defects. Impact on Modern Manufacturing The introduction of progressive dies has had a profound impact on modern manufacturing. Their ability to streamline production processes, improve quality, and reduce costs has made them an indispensable tool in various industries. Manufacturers can meet the ever-increasing demand for precision-engineered components while remaining competitive in a global marketplace. In conclusion, progressive dies represent a remarkable leap forward in manufacturing technology. Their innovative design and widespread applications have reshaped the industry by enabling efficient, high-quality production. As technology continues to advance, it is likely that progressive dies will continue to play a pivotal role in shaping the future of manufacturing.