Metal stamping is a manufacturing process that plays a pivotal role in various industries, from automotive to electronics, and beyond. These meticulously crafted metal stamping parts are the unsung heroes behind countless products we use daily. In this article, we will delve into the world of metal stamping parts, exploring their significance, the process behind their creation, and their wide-ranging applications.

The Significance of Metal Stamping Parts

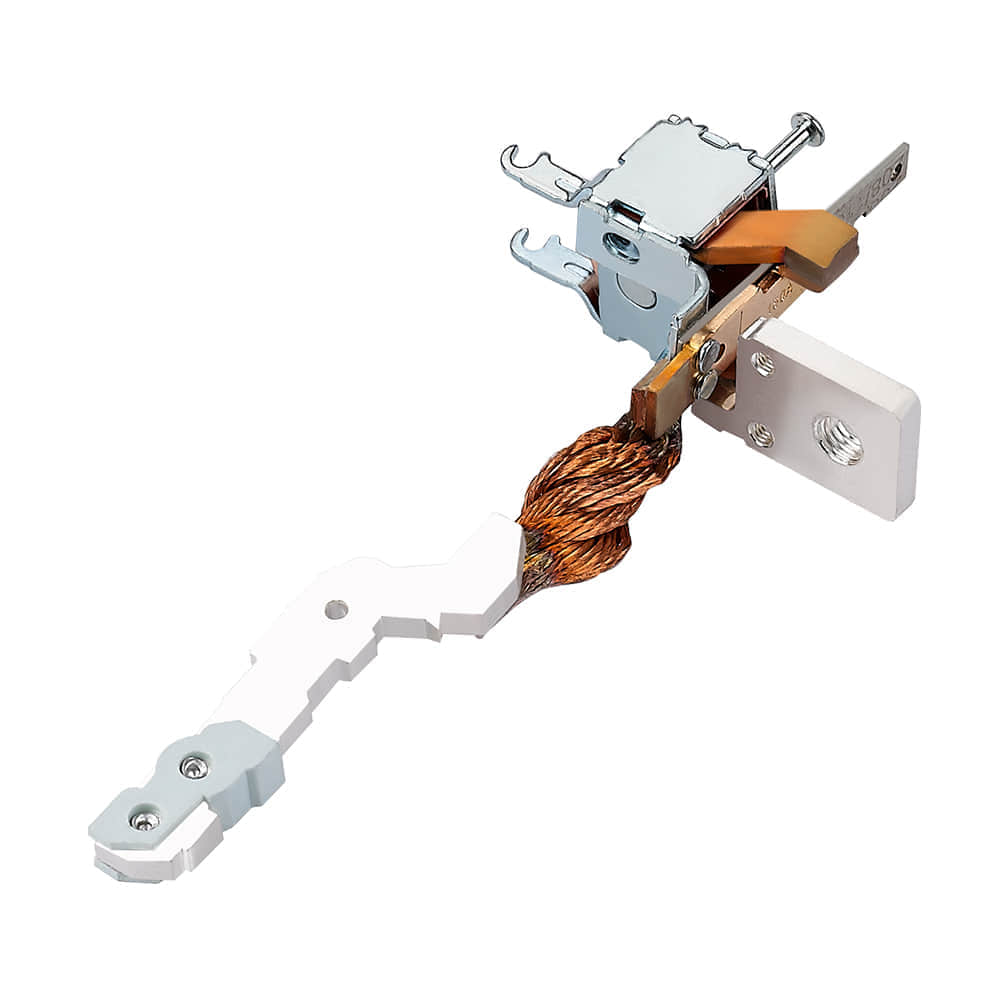

Metal stamping parts are crucial components in the manufacturing sector, offering a multitude of benefits. Their precision and reliability make them a preferred choice for creating intricate shapes and designs. They excel in mass production, ensuring uniformity and consistency in every piece. The versatility of materials they can work with, including steel, aluminum, copper, and various alloys, makes them indispensable across industries. The Metal Stamping Process The metal stamping process involves the use of specialized machinery to transform flat metal sheets or coils into desired shapes and sizes. Here’s a simplified overview of the process: Material Selection: The first step is selecting the appropriate metal material, which depends on the application’s requirements, such as strength, conductivity, or corrosion resistance. Blanking: In this phase, the metal sheet or coil is cut into flat pieces, known as blanks, with the help of a cutting die. This step forms the foundation of the stamping process. Stamping: The blank is then placed into a stamping press, where it undergoes a series of operations. These operations include bending, punching, coining, and more, which are performed using carefully designed dies and punches. Forming: Forming dies are used to shape the metal blanks into the desired forms. This can include deep-drawing for creating three-dimensional shapes or simple bending for producing brackets or clips. Assembly: Some metal stamping parts require assembly. These parts may have multiple components that are welded, riveted, or joined in another way to create the final product. Quality Control: Rigorous quality control measures are implemented throughout the process to ensure that each stamped part meets the specified tolerances and standards. Finishing: After the stamping process, parts may undergo finishing operations such as cleaning, deburring, coating, or plating to enhance their appearance and functionality. Applications of Metal Stamping Parts Metal stamping parts find applications in various industries, including: Automotive: Metal stamping parts are widely used in the automotive sector for manufacturing components like body panels, chassis parts, brackets, and engine components. Electronics: In the electronics industry, metal stamping parts are utilized to create connectors, terminals, and shielding components that are essential for the functionality and reliability of electronic devices. Aerospace: Aerospace manufacturers rely on metal stamping to produce precision parts for aircraft, including structural components, fasteners, and interior fittings. Medical Devices: Metal stamping is essential for manufacturing components in medical devices such as surgical instruments, diagnostic equipment, and implantable devices. Appliances: Many household appliances, such as washing machines, refrigerators, and ovens, incorporate metal stamping parts in their construction for durability and precision. Construction: The construction industry uses metal stamping parts in the fabrication of structural components, brackets, and connectors. Telecommunications: Metal stamping is employed in the production of telecommunications equipment, including antenna components and enclosures. In conclusion, metal stamping parts are the backbone of many industries, providing the precision and reliability needed to create a wide range of products. This manufacturing process showcases the marriage of technology, craftsmanship, and innovation. Whether it’s the car you drive, the phone you use, or the medical equipment that saves lives, chances are, metal stamping parts have played a crucial role in their production. Their importance in modern manufacturing cannot be overstated, making them an essential element in our everyday lives.