In the world of modern manufacturing, injection molded parts have emerged as a cornerstone technology. These versatile components are found in everything from the plastic casing of your smartphone to the intricate components of a spacecraft. While they may appear deceptively simple, injection molded parts are a testament to the precision and innovation that define contemporary engineering.

The Art of Injection Molding

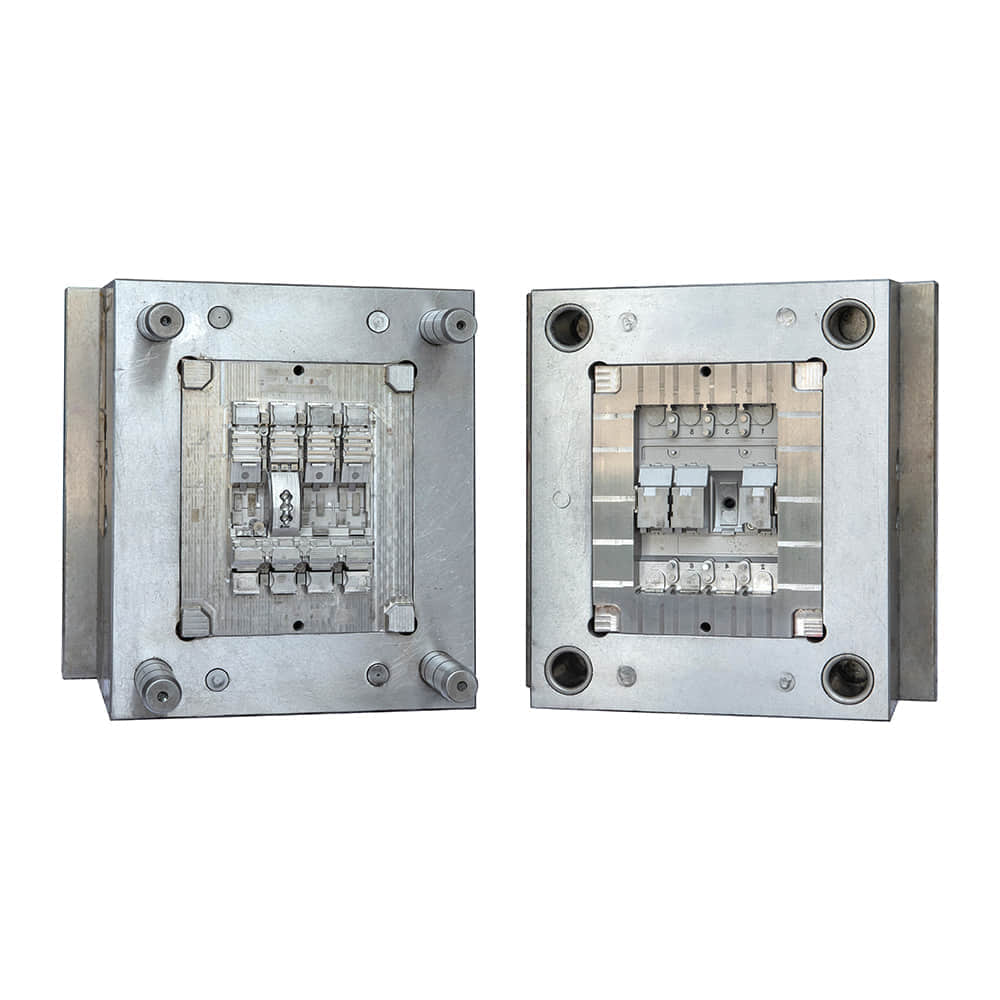

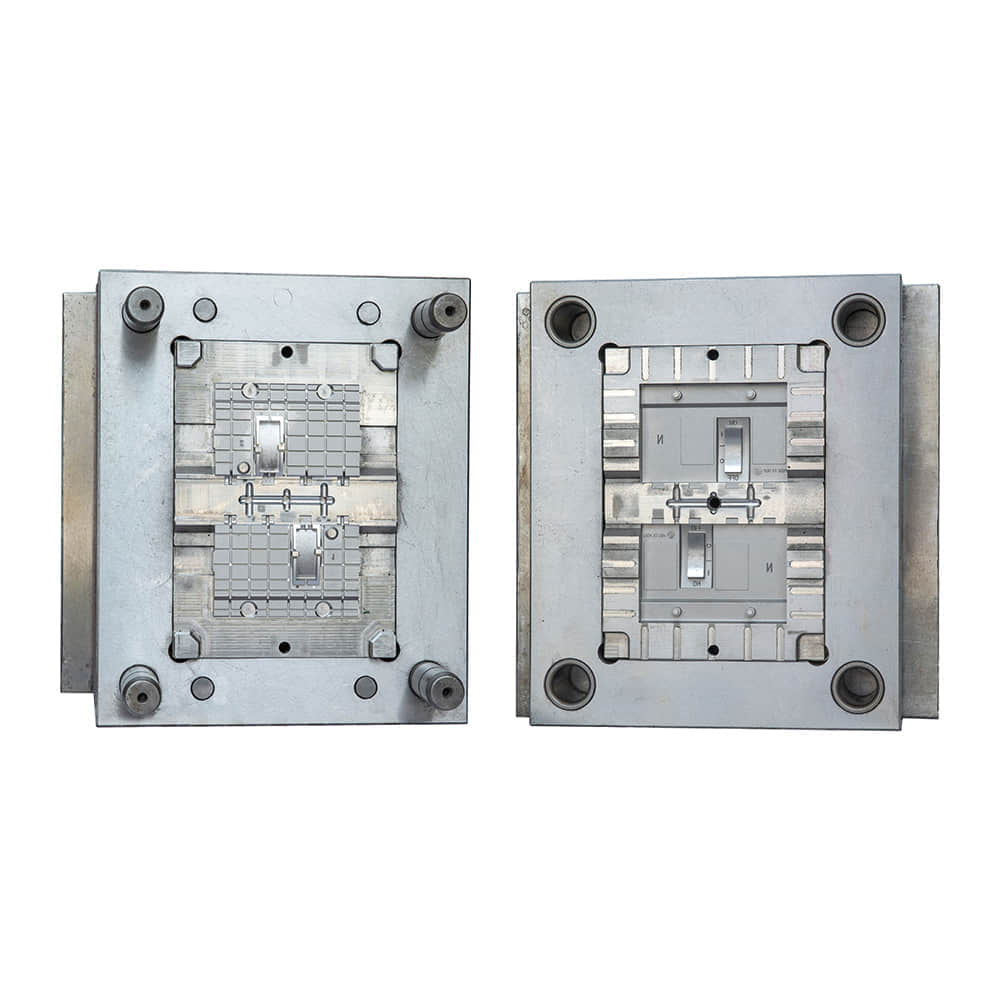

Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity. Once cooled and solidified, the mold is opened to reveal a finished part. It may seem straightforward, but the devil, as they say, is in the details. Precision at Every Stage The journey of creating an injection molded part begins with meticulous design and engineering. CAD (Computer-Aided Design) software is used to create a digital blueprint of the part. This includes not only the outer dimensions but also the intricate internal features. Engineers must consider factors like material selection, wall thickness, and structural integrity during this phase. A tiny flaw in the design can lead to costly defects in the final product. Next, a mold is crafted with impeccable precision. These molds, typically made from steel or aluminum, must withstand extreme pressure and temperature. The mold’s design must mirror the intended part’s specifications exactly. Even a minor deviation can result in parts that don’t fit together or perform as intended. Materials Matter The choice of material for injection molding is critical. Different plastics offer various properties, such as flexibility, strength, and heat resistance. Engineers select the material that best suits the intended application. The plastic pellets are then carefully measured and fed into the injection molding machine. Temperature and pressure are tightly controlled to ensure consistent results. The Dance of Precision Once the mold and material are prepared, the injection molding machine takes center stage. It’s here that the magic happens. The molten plastic is injected into the mold with remarkable speed and accuracy. High pressures are applied to ensure that the plastic flows into every nook and cranny of the mold, capturing the finest details. Precision is not only about speed and pressure but also about repeatability. Injection molding machines are engineered to deliver consistent results, part after part. This reliability is essential in industries where even the tiniest variation can lead to product failure. Quality Assurance Quality control is another critical aspect of injection molding. Each part is carefully inspected for defects. Automated systems and skilled technicians work hand in hand to ensure that only flawless parts make it to the final assembly line. Even the slightest imperfection can lead to product recalls, costly rework, and damage to a brand’s reputation. Applications Across Industries The versatility of injection molded parts is staggering. From medical devices to automotive components, consumer electronics to aerospace, these parts are the unsung heroes of modern life. They are lightweight yet durable, cost-effective yet highly engineered. Injection molding allows for complex geometries that would be impossible or prohibitively expensive to achieve with other manufacturing methods. A Sustainable Future In addition to their precision and versatility, injection molded parts are increasingly playing a role in sustainability efforts. Many manufacturers are embracing recycled plastics and more environmentally friendly materials. The efficiency of injection molding minimizes waste, and the durability of the resulting parts ensures a longer product life, reducing the need for replacements. Conclusion Injection molded parts are a testament to the marriage of precision engineering and advanced manufacturing techniques. They are the building blocks of our modern world, hidden in plain sight within the products we use every day. From the design phase to quality control, precision is the guiding principle that ensures these unassuming components perform their roles reliably and effectively across industries. As technology advances and sustainability becomes paramount, injection molding will continue to evolve, shaping a more efficient, eco-friendly, and precise future.