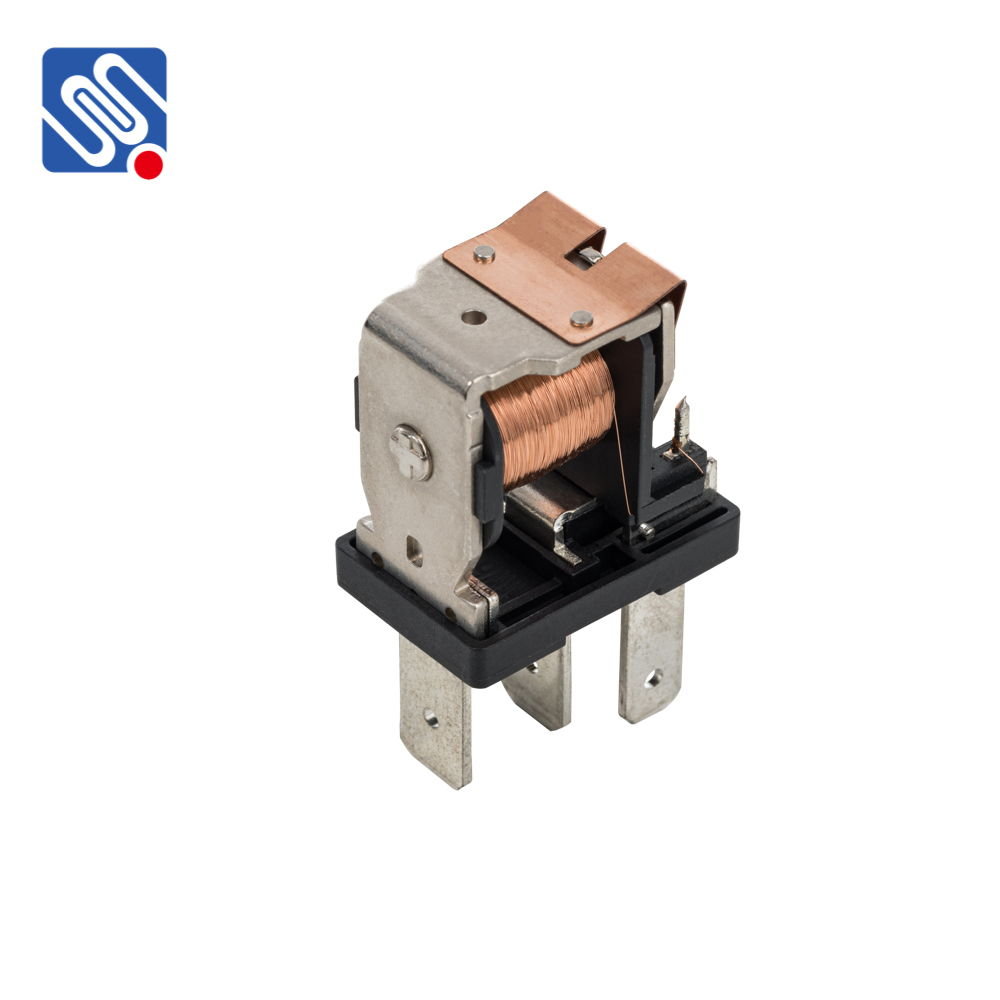

Relays are essential components in modern electrical systems, acting as electromagnetic switches that control high-voltage circuits with low-voltage signals. These components are widely used in various applications, including automotive systems, industrial equipment, and communication devices. The performance and durability of relays rely heavily on the materials used in their construction, often referred to as relay materials. In this article, we will explore the key materials used in relays, their properties, and how they contribute to the overall functionality and reliability of these critical components.

1. Relay Contact Materials One of the most important aspects of a relay is its contacts, as they determine the ability of the relay to switch electrical signals with minimal wear and maximum conductivity. The contact materials must exhibit several key properties such as high electrical conductivity, resistance to oxidation, wear resistance, and thermal stability. Silver Alloys Silver is the most common material used for relay contacts because of its excellent electrical conductivity. However, pure silver is too soft for high-wear applications, so it is often alloyed with other metals to improve its durability. Common silver alloys used for relay contacts include: