In industries ranging from petroleum and chemical processing to pharmaceuticals, the safety and reliability of equipment are paramount. Among the various types of valves used in these settings, the explosion-proof electric butterfly valve stands out due to its crucial role in controlling fluid flow while ensuring safety in potentially hazardous environments. As a result, choosing the right explosion-proof electric butterfly valve manufacturer becomes a vital decision for ensuring operational efficiency and safety.

Understanding Explosion-proof Electric Butterfly Valves

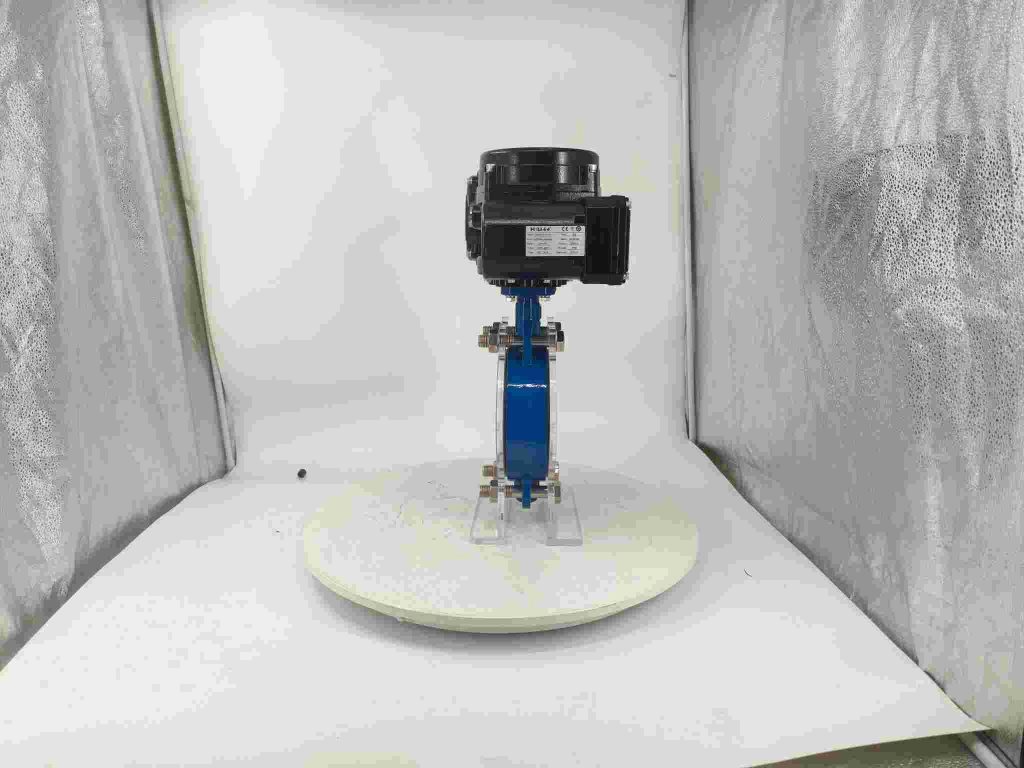

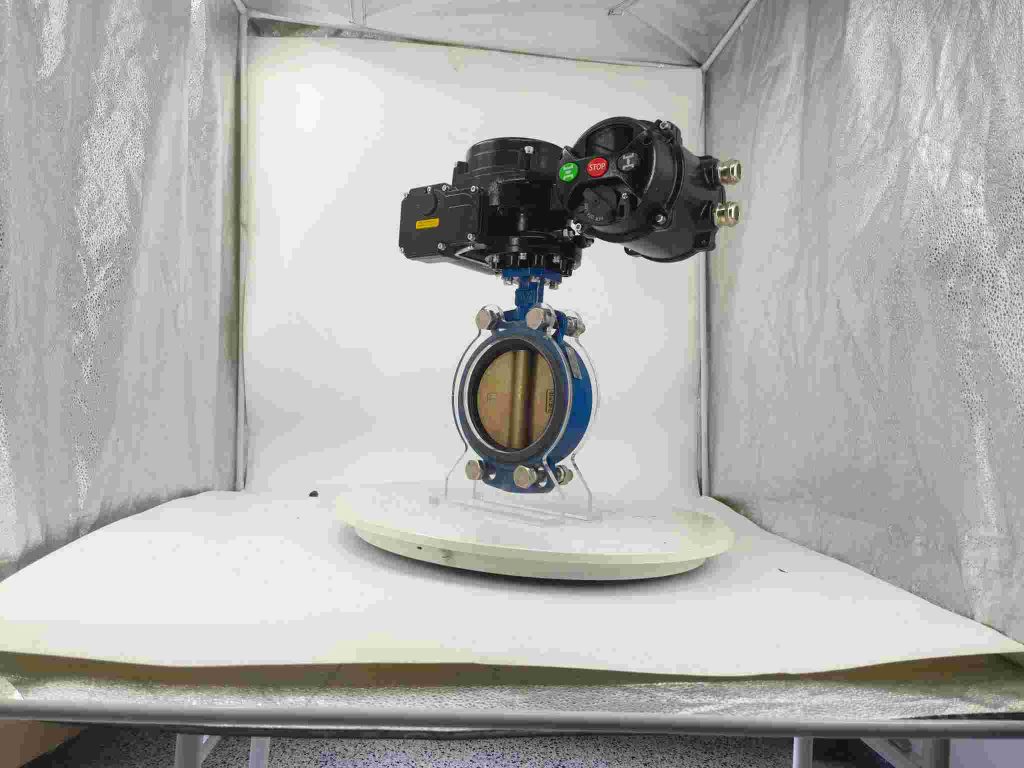

Explosion-proof electric butterfly valves are specifically designed to prevent ignition sources that could lead to explosions in environments where flammable gases or dust may be present. This is achieved through careful design and material selection, ensuring that the valve operates safely under extreme conditions. These valves are typically installed in pipelines to regulate the flow of liquids or gases, making them essential components in various industrial applications. The Role of Manufacturers Manufacturers of explosion-proof electric butterfly valves must adhere to strict industry standards and regulations to ensure that their products are safe and reliable. This often includes compliance with international certifications such as ATEX and IECEx. These certifications indicate that the valves have been tested and verified to operate safely in explosive atmospheres, providing peace of mind to operators in high-risk industries.