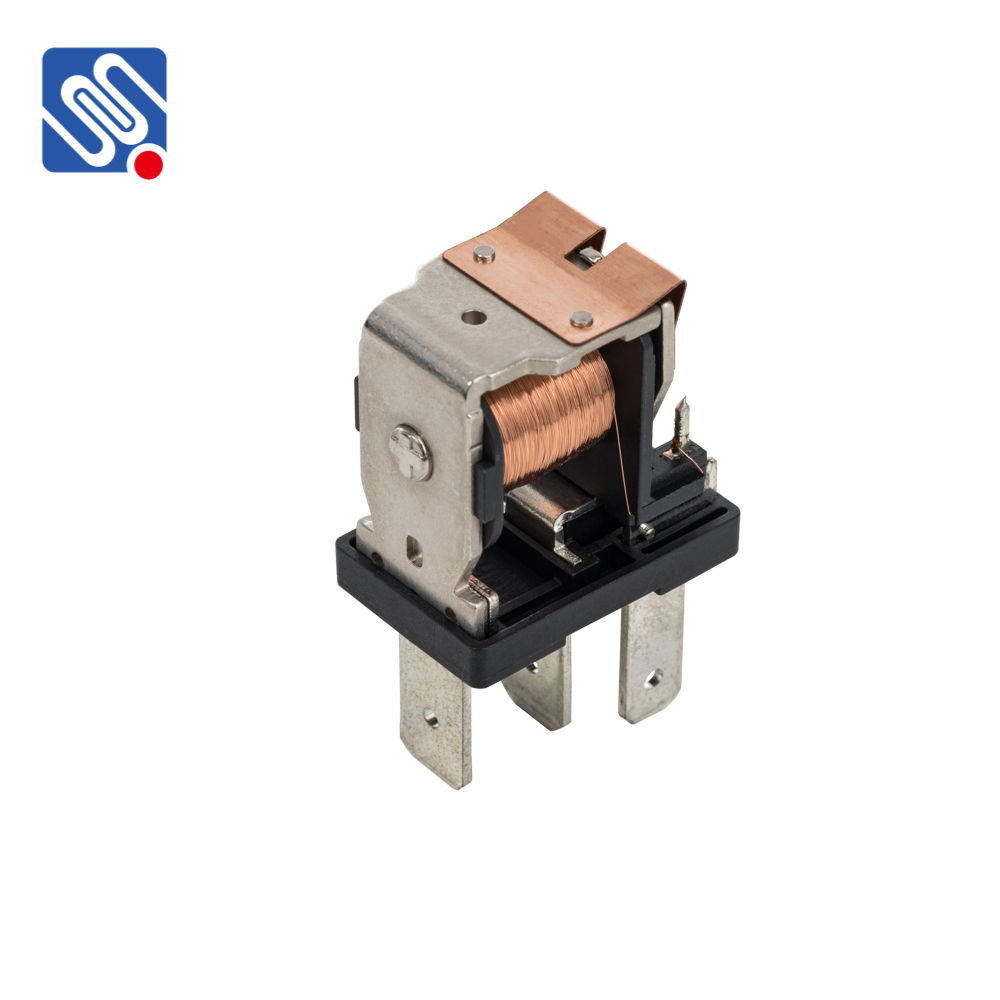

Relay materials play a pivotal role in ensuring the efficiency and reliability of relay systems in electrical and electronic applications. These materials, which are specifically chosen for their conductive, magnetic, and insulating properties, are the backbone of relay components such as contacts, coils, and housings. Relays themselves are electrical devices used to control the flow of current in a circuit by opening or closing contacts, often in response to an electrical signal. This capability is vital for automating systems and enabling the precise control of high-power circuits with low-power signals. The materials used in relays significantly impact their functionality, performance, and longevity.

Conductive Materials: The Heart of Relay Functionality One of the most crucial aspects of relay materials is the conductive components, which are responsible for the seamless transmission of electrical signals. Conductivity is an essential property that ensures minimal energy loss when the relay is operating. Metals like silver, gold, and copper are commonly used for the contacts in relays due to their superior conductivity. Silver is particularly favored because of its excellent electrical properties, ensuring low resistance and high current-carrying capability. However, silver can tarnish over time, which can affect its performance. To mitigate this, silver alloys are often used, which may include small amounts of palladium or gold. These alloys enhance the corrosion resistance of the contacts and improve their durability, ensuring long-term performance even in harsh environments. Gold is sometimes used for smaller relays, such as in telecommunications, due to its high corrosion resistance and ability to maintain good conductivity over time.