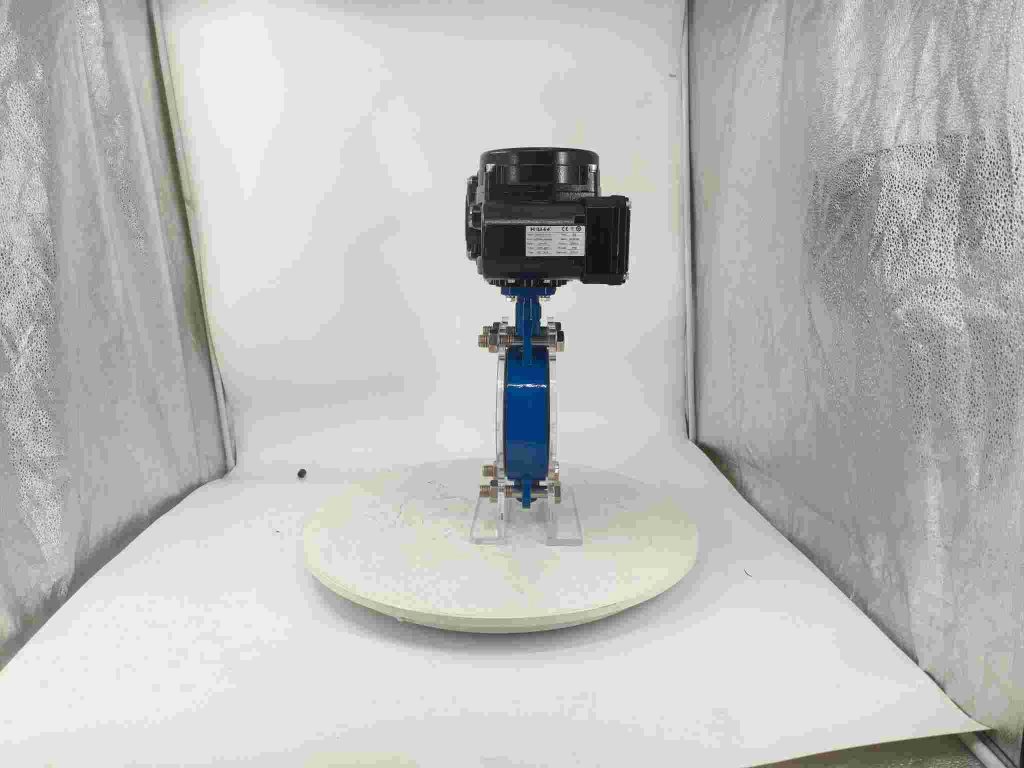

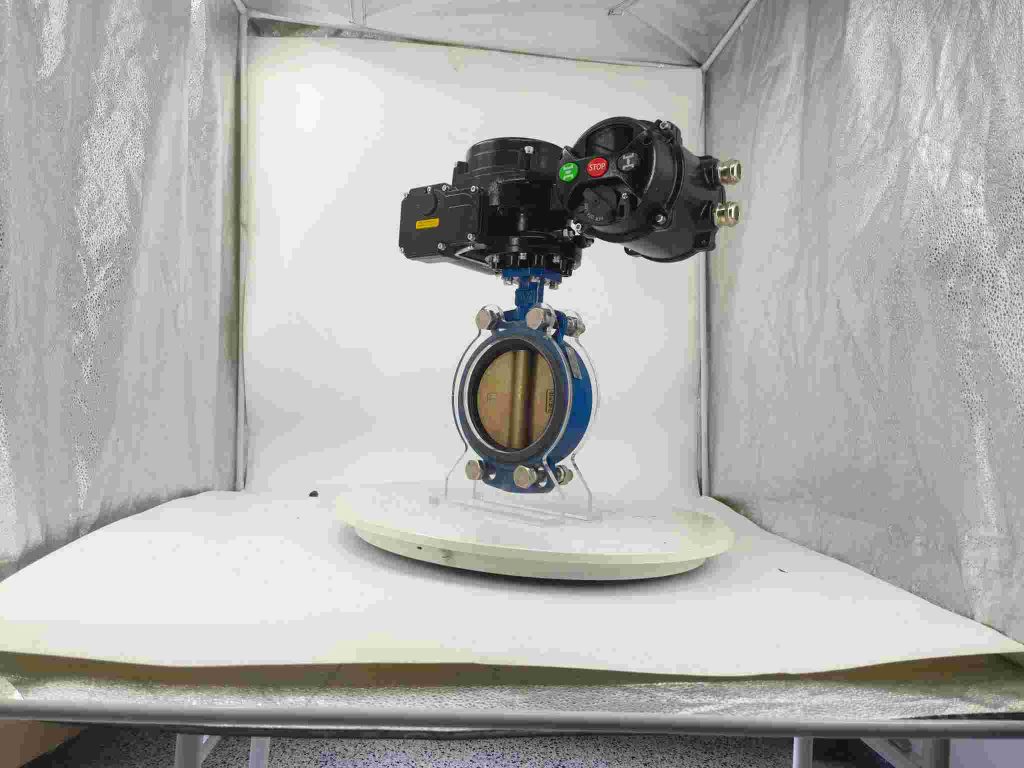

The WCB Explosion-Proof Electric Butterfly Valve is a highly specialized valve designed for use in environments where hazardous conditions and the potential for explosions are a concern. As industries strive for safety, durability, and efficiency, these valves have become indispensable in systems where controlled fluid regulation is vital. This article explores the significance, construction, and benefits of the WCB Explosion-Proof Electric Butterfly Valve in industrial applications.

What is a WCB Explosion-Proof Electric Butterfly Valve?

A WCB Explosion-Proof Electric Butterfly Valve is a type of valve used to control the flow of fluids through pipelines. The “WCB” refers to the material of the valve body—carbon steel (Weldable Carbon Steel). “Explosion-proof” indicates that the valve is designed to withstand potential explosive conditions, ensuring safe operation in environments that are at risk of igniting flammable gases, dust, or vapors. The valve is operated electrically, providing precise and efficient control over fluid flow. Key Features and Construction The primary components of a WCB Explosion-Proof Electric Butterfly Valve include the valve body, actuator, and seat. The valve body is made of WCB carbon steel, which is known for its strength, durability, and resistance to wear and corrosion. The actuator, typically electric, is what powers the opening and closing of the valve, making it ideal for remote operation and automation.