In the realm of industrial automation, the need for reliable and safe equipment cannot be overstated. One critical component that plays a vital role in controlling the flow of various substances is the butterfly valve. Among the many types of butterfly valves, the explosion-proof electric butterfly valve stands out, especially in industries where flammable or explosive materials are handled. This article delves into the significance of explosion-proof electric butterfly valves and highlights the role of OEM manufacturers in providing quality solutions.

Understanding Explosion-proof Electric Butterfly Valves

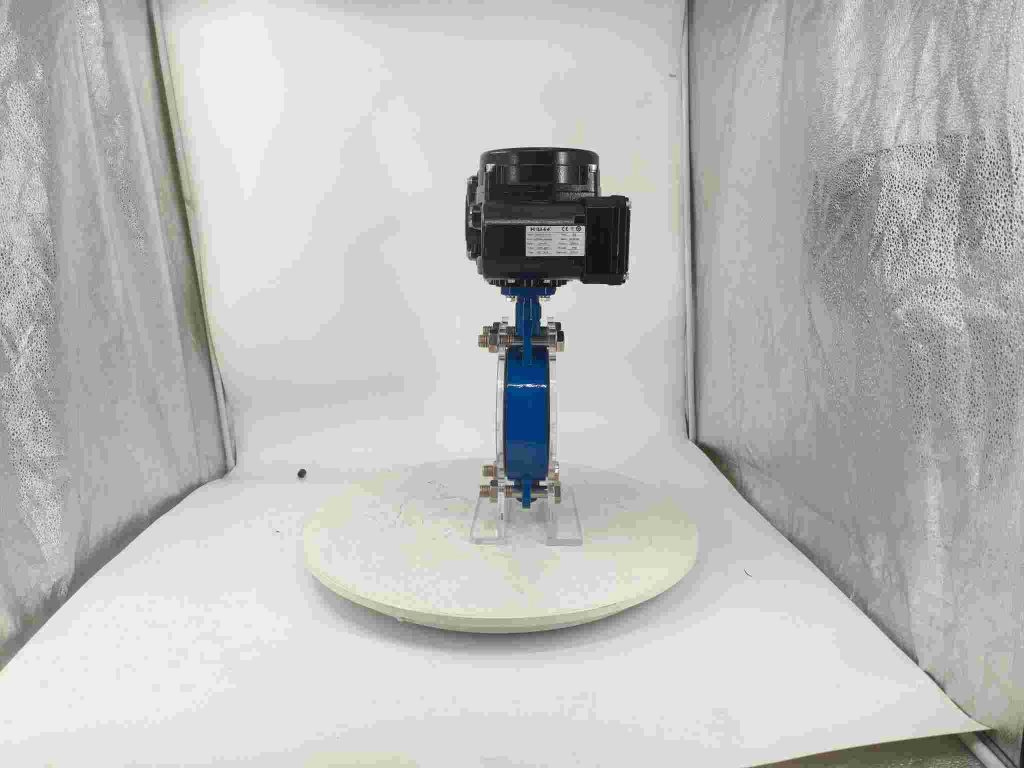

Explosion-proof electric butterfly valves are specifically designed to function safely in environments with a high risk of explosions or fires. These valves combine the functionality of traditional butterfly valves with electric actuators, allowing for remote operation and precise control of flow. The explosion-proof design ensures that even if an internal fault occurs, the valve will not ignite flammable substances in its vicinity. The valve’s construction typically includes robust materials that can withstand high pressures and extreme temperatures, making them suitable for applications in the oil and gas, chemical, and pharmaceutical industries. These industries often deal with hazardous materials, where even a small failure can lead to catastrophic consequences. Therefore, choosing the right valve is essential for maintaining safety standards and compliance with industry regulations.