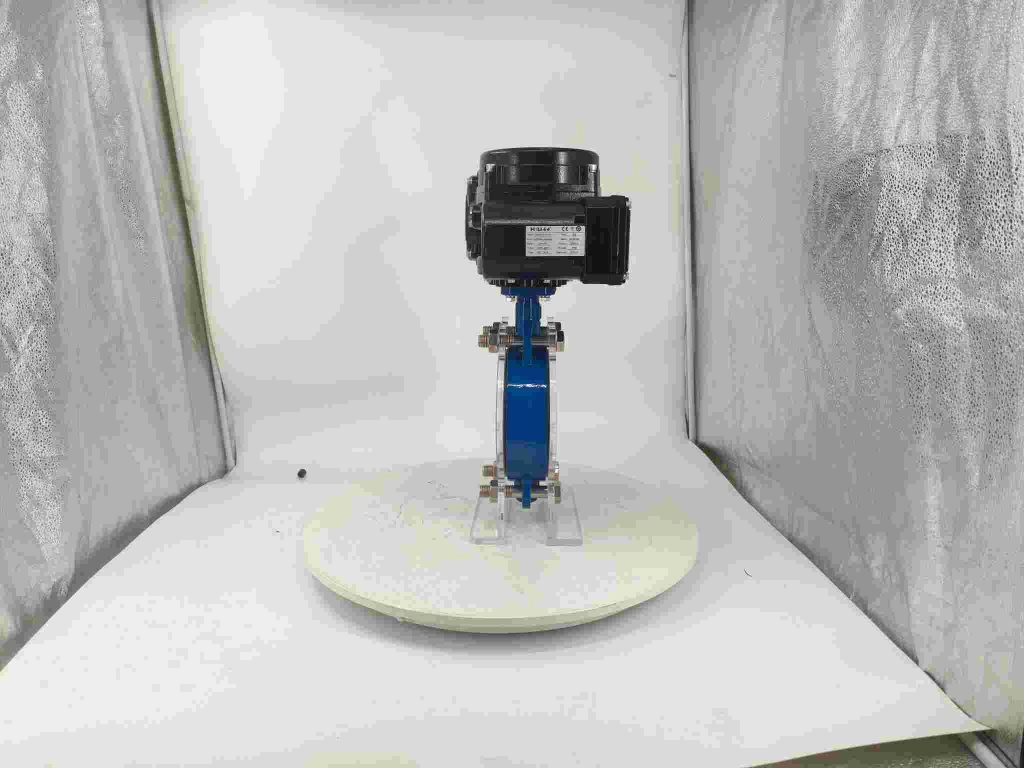

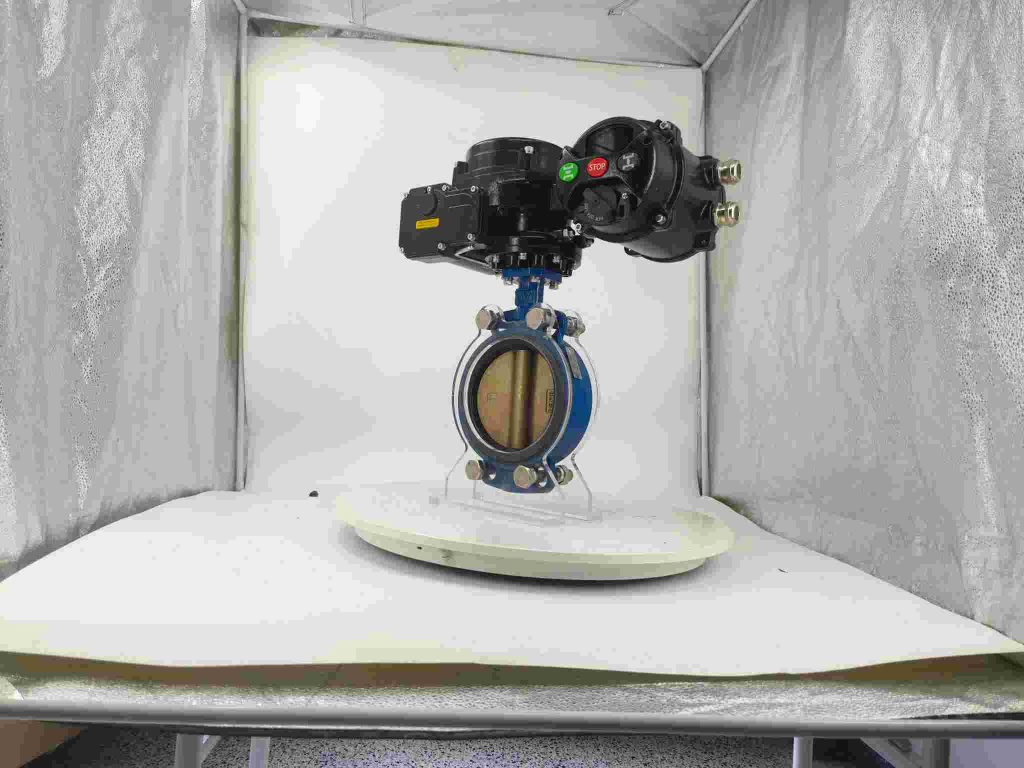

In the industrial landscape, the role of valves cannot be overstated. They are crucial components in fluid control systems, regulating the flow of liquids and gases in various applications. Among these valves, explosion-proof electric butterfly valves stand out due to their unique ability to provide both safety and efficiency in potentially hazardous environments. This article delves into the world of explosion-proof electric butterfly valve manufacturers, exploring their significance, challenges, and contributions to the industrial sector.

The Significance of Explosion-proof Electric Butterfly Valves

Explosion-proof electric butterfly valves are designed to withstand the rigors of explosive environments while maintaining reliable fluid control. These valves are essential in industries like petroleum, chemicals, pharmaceuticals, and energy, where the handling of flammable or explosive fluids is commonplace. Their ability to withstand extreme conditions without compromising performance makes them a crucial part of any safety-critical fluid control system. Challenges Faced by Manufacturers Manufacturing explosion-proof electric butterfly valves is a complex task that requires precision engineering and strict adherence to safety standards. Manufacturers must ensure that their valves can withstand high temperatures, pressures, and explosive atmospheres without failing. This requires a deep understanding of materials science, fluid dynamics, and electrical safety.