Metal stamping parts are an integral aspect of modern manufacturing, playing a crucial role in industries ranging from automotive and electronics to aerospace and beyond. This advanced technique allows manufacturers to create intricate, accurate, and high-quality components that serve as the building blocks for various products we use daily. In this article, we will delve into the world of metal stamping, exploring its process, applications, and advantages.

The Metal Stamping Process: Precision Redefined

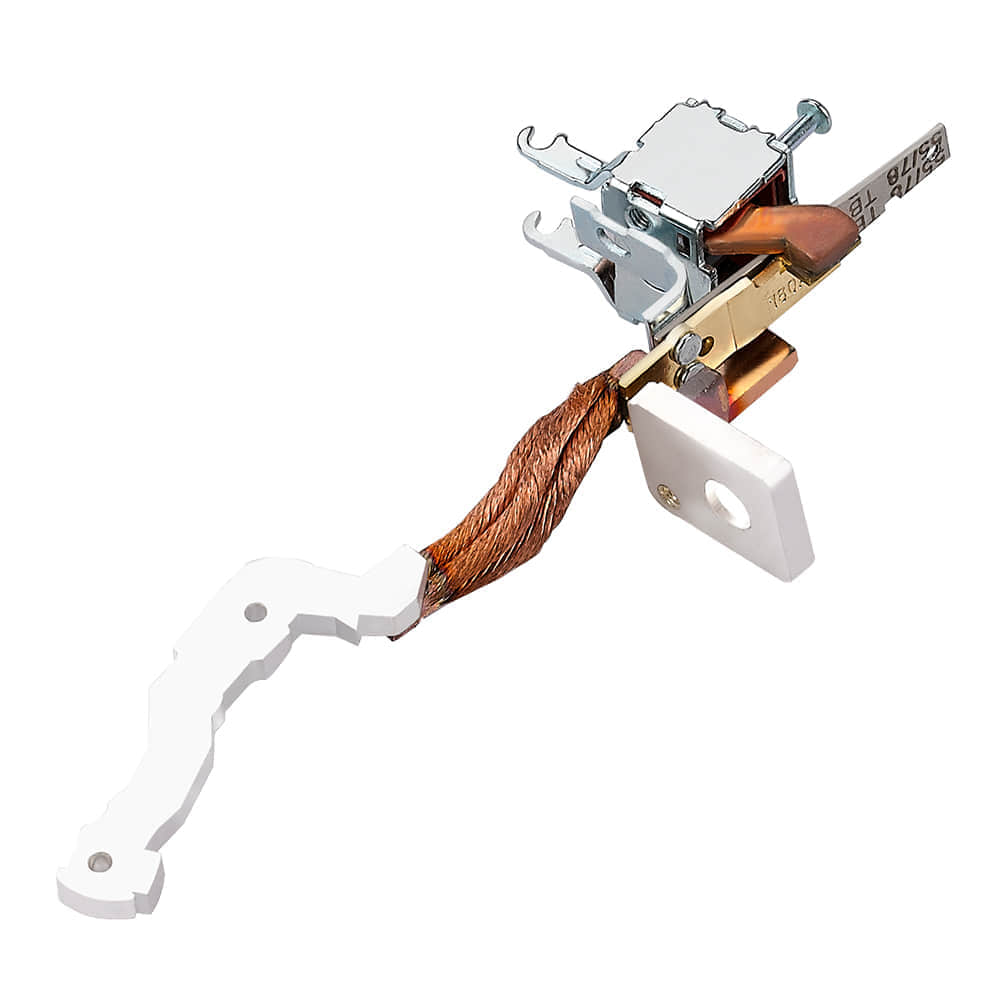

Metal stamping is a manufacturing process that involves transforming flat metal sheets into specific shapes through pressing, forming, bending, and cutting. The process typically involves a series of intricate steps, including die design and fabrication, material selection, and stamping. Dies are specialized tools used to shape the metal sheets according to the desired specifications, often requiring precision engineering to ensure consistency and quality in the final product. Applications Across Industries Metal stamping parts find their application in a wide array of industries, showcasing their versatility and significance in modern production. One of the prominent sectors benefiting from metal stamping is the automotive industry. From structural components to intricate parts like gears and engine components, metal stamping ensures the production of parts that are not only durable but also contribute to the overall safety and performance of vehicles. The electronics industry also heavily relies on metal stamping for producing components like connectors, terminals, and heat sinks. The precision offered by this process is crucial in electronics, as it enables seamless integration and optimal functioning of various devices, from smartphones to complex medical equipment. Furthermore, metal stamping caters to the demands of the aerospace industry by crafting parts that meet strict quality and safety standards. Whether it’s intricate brackets or panels, these parts contribute to the structural integrity and operational efficiency of aircraft and spacecraft. Advantages of Metal Stamping The use of metal stamping parts presents several advantages that make it a preferred manufacturing technique: Precision:Metal stamping allows for the creation of intricate and precise parts with tight tolerances, ensuring consistency and reliability in the end product. Cost-Efficiency:Once the dies are created, the actual stamping process becomes highly efficient and can produce parts at a rapid rate, reducing overall manufacturing costs. Versatility:Metal stamping can be applied to a variety of metals, including steel, aluminum, copper, and alloys, expanding its potential applications. High Volume Production:Metal stamping is well-suited for high-volume production runs, making it ideal for industries that require large quantities of consistent parts. Minimal Material Waste:The process minimizes material waste as it involves cutting shapes from a flat sheet, optimizing material usage. Complex Shapes:The technology allows for the creation of complex geometries that might be challenging or expensive to achieve through other methods. Challenges and Future Trends While metal stamping offers numerous benefits, it also presents challenges. Designing intricate dies, selecting appropriate materials, and ensuring consistent quality throughout large production runs can be demanding. However, advancements in computer-aided design (CAD) and simulation software have significantly improved the accuracy and efficiency of the process. Looking ahead, the industry is likely to embrace further automation and digitalization. Robotics and AI-driven quality control systems can enhance precision and reduce the margin of error. Additionally, as sustainability gains prominence, metal stamping can contribute by optimizing material usage and minimizing waste. In Conclusion Metal stamping parts have revolutionized modern manufacturing by providing precise, efficient, and versatile solutions across industries. From automobiles to electronics and aerospace, metal stamping plays a vital role in shaping the products that define our lives. As technology continues to evolve, so too will the capabilities of metal stamping, ensuring that it remains a cornerstone of innovation in the manufacturing world.