Metal stamping dies play a crucial role in shaping the modern manufacturing landscape, enabling the efficient production of various metal components used in industries ranging from automotive to electronics. Behind these intricate tools are skilled manufacturers who combine craftsmanship, technology, and innovation to create the backbone of modern manufacturing processes.

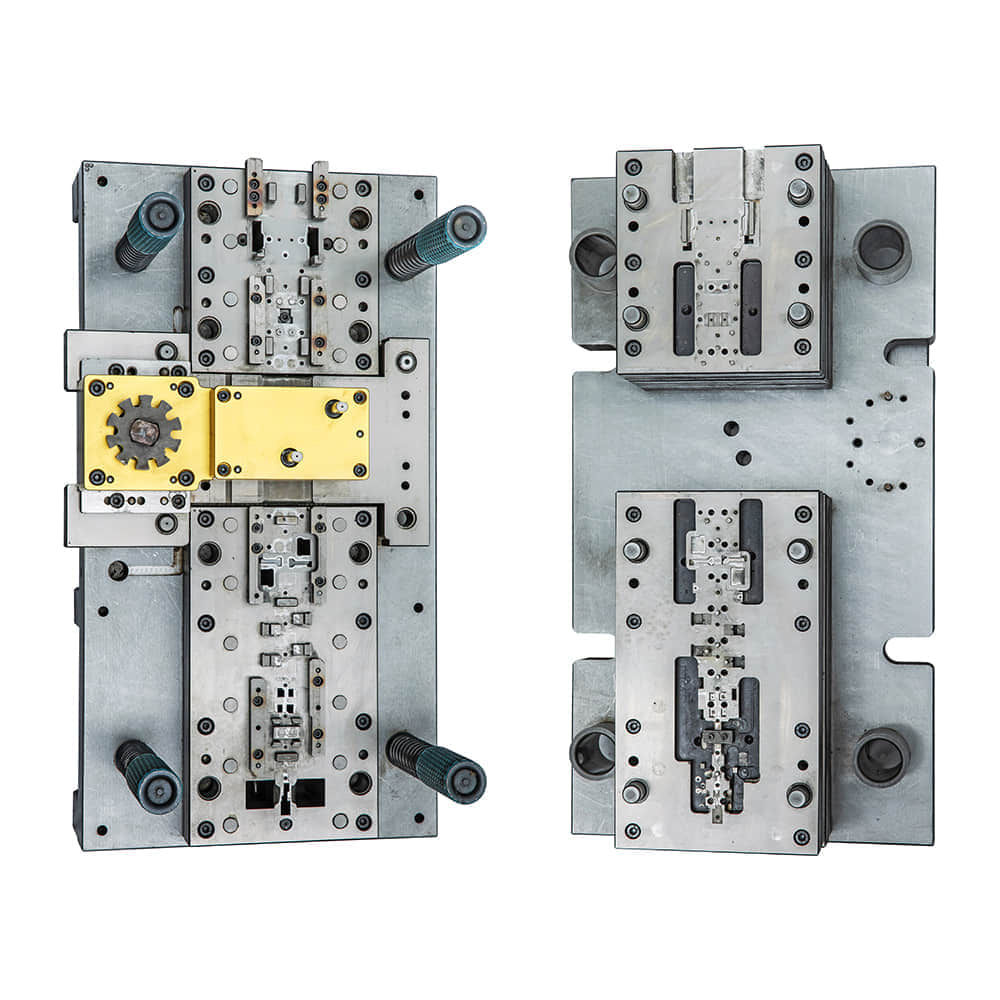

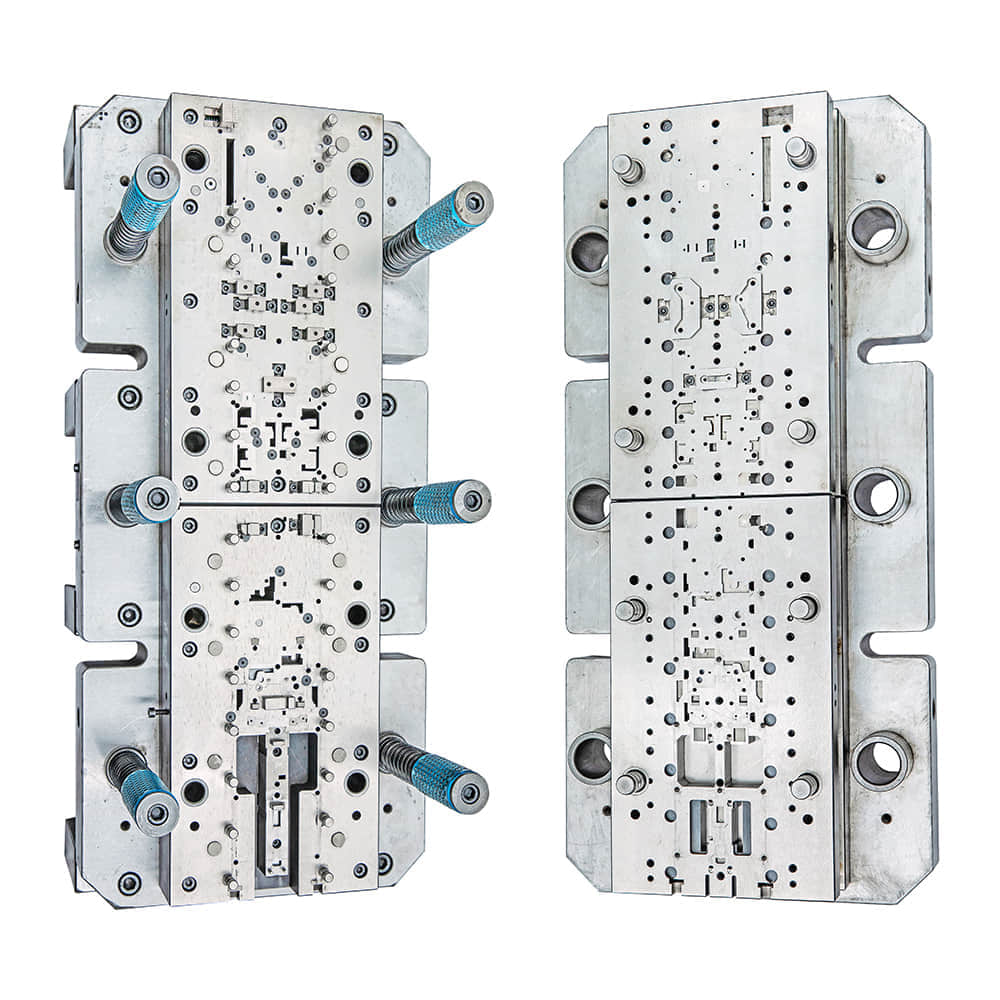

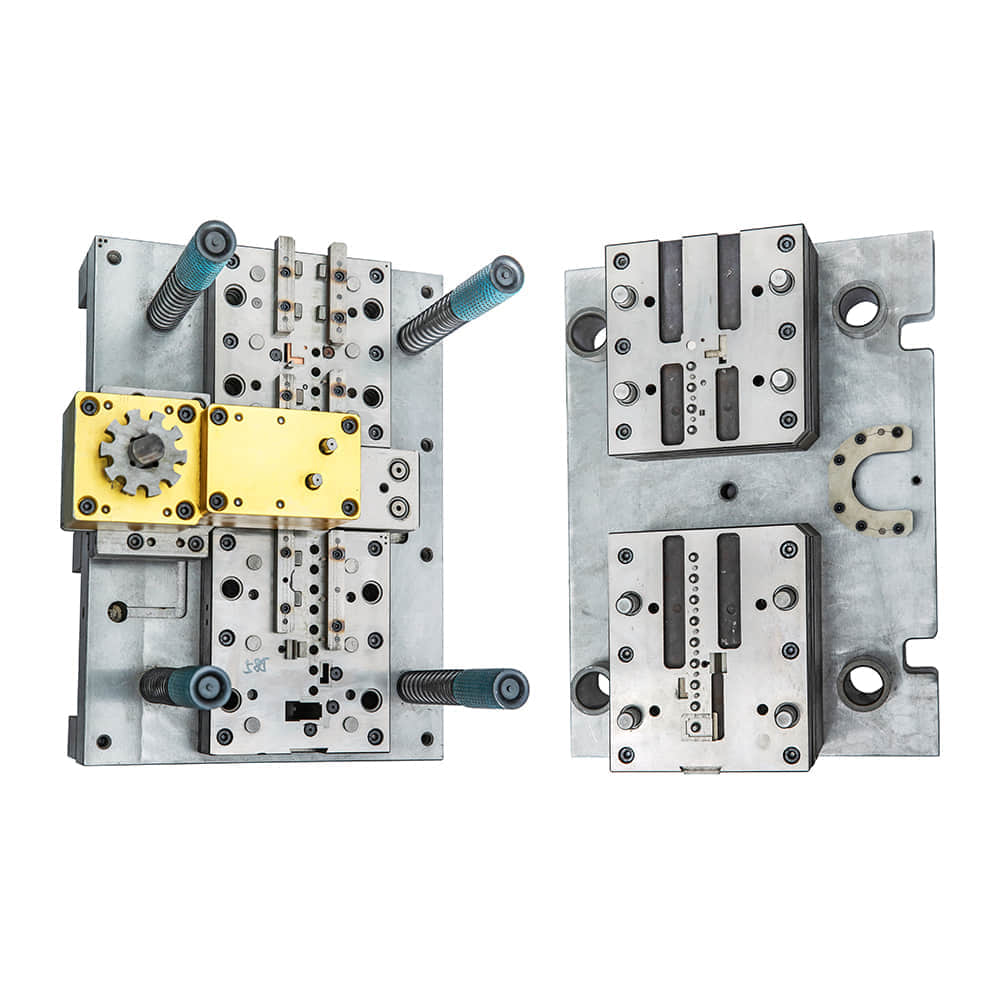

Metal stamping dies, often referred to simply as “dies,” are specialized tools used in metal stamping processes to cut or form metal sheets into desired shapes. These shapes can range from intricate designs to functional components that are integral to everyday products. Metal stamping die manufacturers are the masterminds behind the conception, design, fabrication, and maintenance of these tools.

The manufacturing of metal stamping dies is a multi-faceted process that requires a unique blend of expertise. These manufacturers need to have a deep understanding of metallurgy, engineering principles, and material science. Each die is meticulously crafted to ensure precision, durability, and consistent performance. The process begins with the conceptualization of the design, often using computer-aided design (CAD) software, which allows manufacturers to visualize the final product before manufacturing even begins. Once the design is finalized, manufacturers choose the appropriate materials for the die’s construction. The choice of material depends on factors such as the type of metal being stamped, the expected production volume, and the desired die lifespan. Common materials include various grades of steel, carbide, and even advanced materials like titanium alloys. The manufacturing process might involve CNC machining, wire cutting, and other advanced techniques to shape and form the components of the die. Precision is the hallmark of metal stamping die manufacturing. The tiniest deviation can result in defective components or production downtime. Therefore, manufacturers employ advanced machining and quality control techniques to ensure that every component of the die meets exact specifications. Computer-controlled precision machining tools are used to create the intricate details necessary for stamping accuracy. In recent years, technological advancements have transformed the landscape of metal stamping die manufacturing. Computer simulations and finite element analysis allow manufacturers to test and refine their designs virtually before physical production begins. This not only saves time and resources but also contributes to the overall efficiency of the manufacturing process. Additionally, automation and robotics are being integrated into die manufacturing facilities to enhance production speed while maintaining the highest quality standards. The role of metal stamping die manufacturers extends beyond the initial production phase. Regular maintenance and, if necessary, repairs are essential to ensure the longevity of these valuable tools. Wear and tear are natural consequences of the die’s continuous use, and manufacturers need to possess the expertise to diagnose issues and perform necessary maintenance tasks promptly. In conclusion, metal stamping die manufacturers are the unsung heroes of modern manufacturing. Their expertise and dedication drive the creation of intricate tools that underpin various industries. From the initial design to the final product and beyond, these manufacturers play a vital role in ensuring the efficiency, precision, and quality of metal stamping processes. As technology continues to advance, we can expect even greater innovation in the world of metal stamping die manufacturing, further propelling industries into the future.