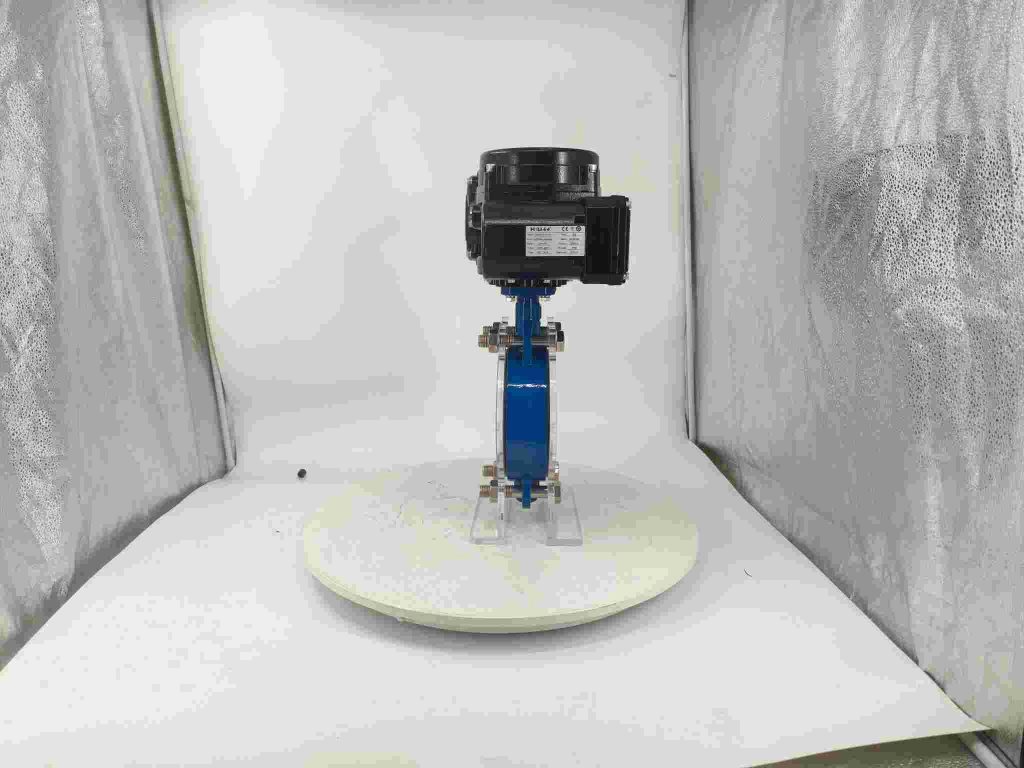

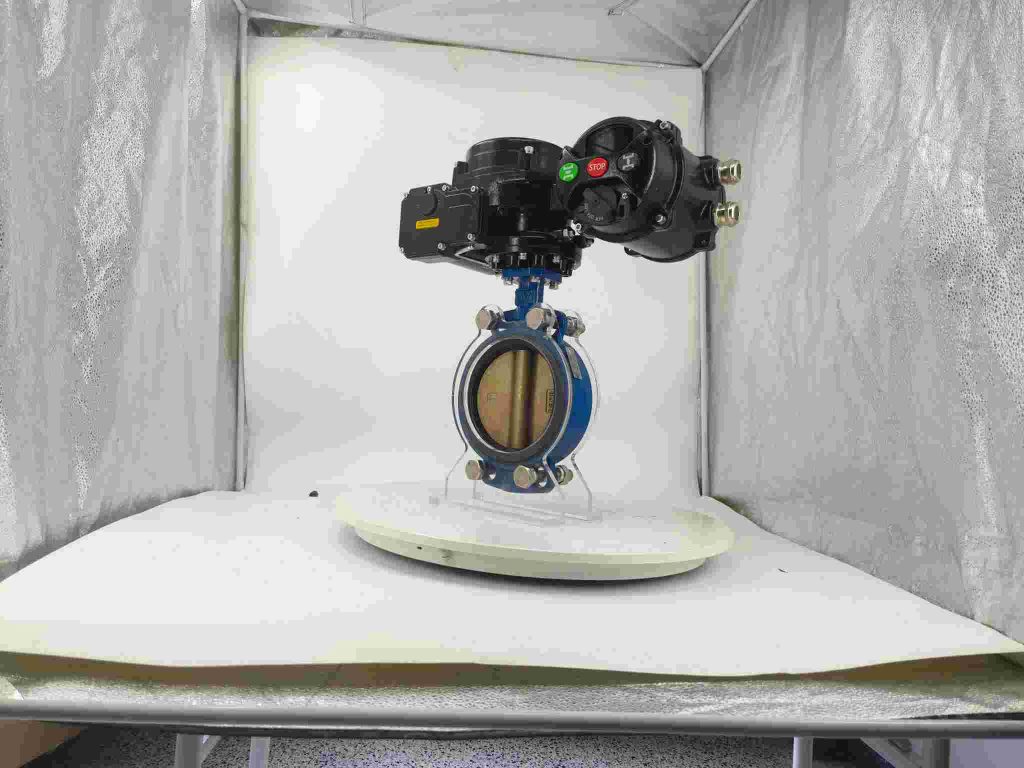

The WCB explosion-proof electric butterfly valve is a crucial component in many industrial systems, particularly in sectors where safety and reliability are paramount. These valves are designed to control the flow of liquids and gases in pipelines while ensuring that hazardous environments remain safe. The combination of the WCB (Water-Cooling Brass) material and explosion-proof electric actuation makes these valves ideal for industries such as petrochemical, oil and gas, pharmaceuticals, and chemical manufacturing, where dangerous substances and volatile conditions are commonplace.

Understanding the WCB Explosion-proof Electric Butterfly Valve

A butterfly valve is a type of flow control device used in a variety of fluid systems to regulate, isolate, or control the flow of liquids or gases. The valve consists of a disk or vane that rotates within a pipe to allow or block the flow. The WCB explosion-proof electric butterfly valve, in particular, features an electric actuator that drives the rotation of the disk, offering a precise and automated means of flow control. The WCB material used in the construction of these valves is a high-strength, corrosion-resistant alloy, which ensures durability and long service life in harsh environments. The explosion-proof design of the valve further enhances its safety capabilities, allowing it to function effectively in potentially explosive atmospheres, such as those found in the oil and gas industry. This explosion-proof feature is critical to preventing the ignition of hazardous gases or dust that could lead to dangerous explosions or fires.