In the realm of industrial automation, the demand for robust and reliable components is ever-increasing. One such component that stands out in this regard is the explosion-proof electric butterfly valve. These valves are crucial for controlling the flow of fluids in hazardous environments where safety and precision are paramount. As industries seek advanced solutions, the role of an ODM (Original Design Manufacturer) specializing in explosion-proof electric butterfly valves has become increasingly significant.

Explosion-proof electric butterfly valves are designed to operate safely in environments prone to explosive atmospheres. They are equipped with features that prevent ignition of explosive gases or dust, ensuring both the safety of the operation and the longevity of the valve. These valves are utilized in various industries, including chemical processing, oil and gas, and pharmaceuticals, where the presence of volatile substances is a common concern.

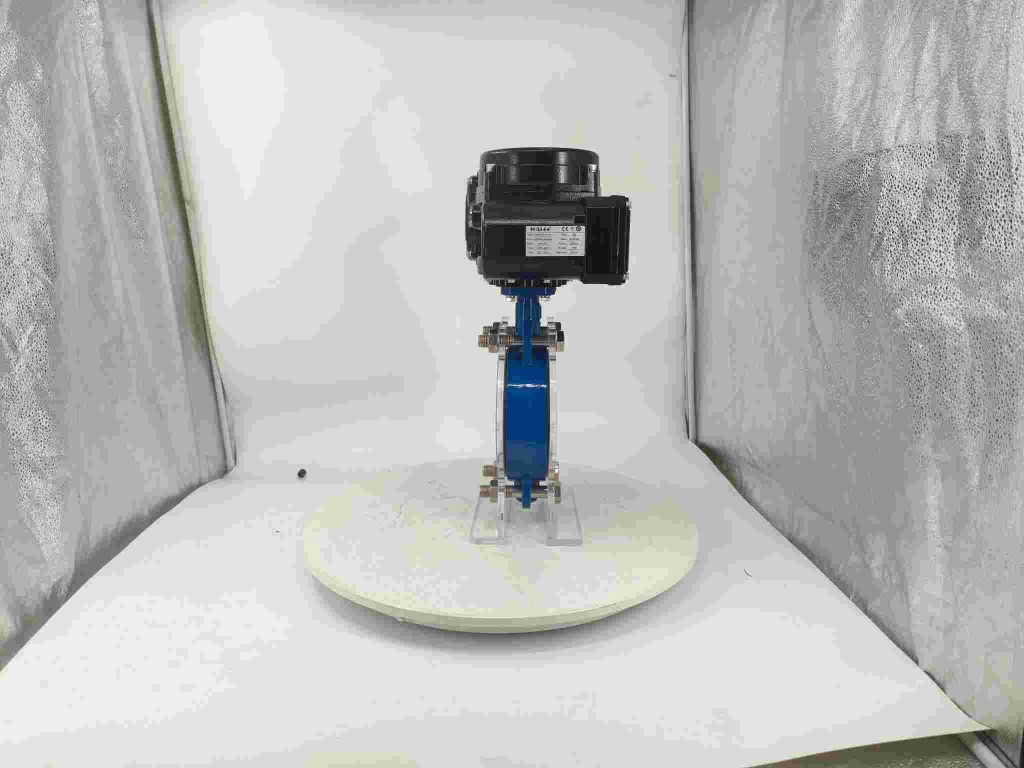

The primary function of an explosion-proof electric butterfly valve is to regulate the flow of fluids by opening, closing, or modulating the valve. The electric actuator embedded in these valves allows for precise control and automation, enhancing operational efficiency and reducing the need for manual intervention. The explosion-proof design is achieved through robust construction and protective measures that meet stringent industry standards, such as ATEX or IECEx certifications. An ODM manufacturer specializing in explosion-proof electric butterfly valves plays a crucial role in this sector. ODM manufacturers offer comprehensive services that include the design, development, and production of custom valves tailored to specific client requirements. These manufacturers leverage their expertise to produce high-quality, reliable valves that adhere to international safety standards. Their ability to provide customized solutions is essential for industries with unique operational needs and stringent safety requirements.