Metal Stamping Parts: Precision in Every Press

In the intricate world of manufacturing, where precision and efficiency reign supreme, metal stamping has emerged as a pivotal process. Metal stamping involves the use of dies and presses to create complex shapes and patterns from metal sheets. This process is not only a cornerstone of modern manufacturing but also a testament to the versatility and advancement of engineering techniques.

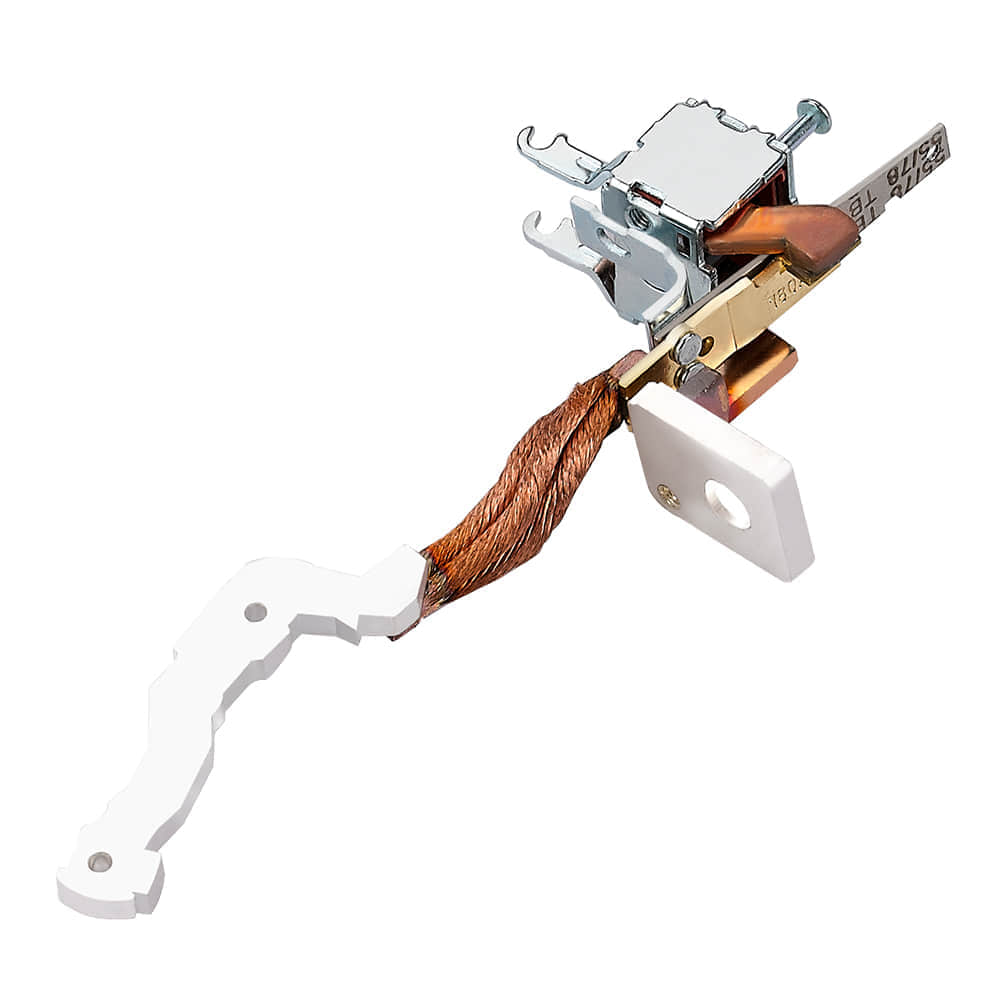

Evolution of Metal Stamping: From Simple to Sophisticated The roots of metal stamping can be traced back to ancient times when metal was first shaped using manual hammers and dies. However, the true evolution of metal stamping began during the Industrial Revolution with the invention of mechanical presses. These presses allowed for increased production rates and greater precision, marking a turning point in manufacturing capabilities. Precision and Consistency One of the most remarkable aspects of metal stamping is its ability to deliver precision and consistency with each press. Computer Numerical Control (CNC) technology further elevated this process by enabling intricate designs to be programmed and executed with incredible accuracy. This precision proves invaluable across industries where uniformity and adherence to tight tolerances are paramount. Versatility Unleashed Metal stamping is a versatile technique that caters to an array of industries such as automotive, aerospace, electronics, and more. It provides a cost-effective solution for producing high-volume components without compromising on quality. From intricate connectors in electronic devices to robust structural elements in automobiles, metal stamping fulfills diverse needs. Material Matters The scope of metal stamping extends beyond common metals like steel and aluminum. Exotic and advanced materials, including titanium and various alloys, can be shaped using stamping techniques. This widens the possibilities for industries that demand specialized materials to meet specific performance requirements. Efficiency in Production The efficiency of metal stamping is amplified by its ability to create multiple features in a single press. This significantly reduces production time and minimizes the need for secondary operations. The result is a streamlined production process that not only accelerates delivery times but also reduces overall costs. Challenges and Innovations Despite its many advantages, metal stamping isn’t without its challenges. Complex designs may require intricate tooling, and material behavior under high pressure needs careful consideration. However, these challenges have spurred innovation. Finite Element Analysis (FEA) and simulation software help predict material behavior, optimizing designs before the physical process begins. Environmental Considerations In an era where environmental consciousness is paramount, metal stamping stands as a sustainable manufacturing option. The process generates minimal waste, as scrap material can often be recycled. Additionally, the durability of stamped metal components contributes to the longevity of end products, reducing the overall environmental impact. The Human-Machine Collaboration While technology drives much of the process, skilled professionals are integral to the success of metal stamping. Die designers, press operators, and quality control personnel ensure that the process runs seamlessly and that the final products meet the highest standards. This collaboration between human expertise and technological prowess highlights the synergy that defines modern manufacturing. Conclusion Metal stamping parts embody the marriage of art and science, where precision engineering meets versatile production. From its humble origins to its current technological sophistication, metal stamping continues to shape industries and push the boundaries of what is possible. As we move forward, the legacy of metal stamping remains a testament to human ingenuity and the relentless pursuit of excellence in manufacturing.