In the realm of modern manufacturing, precision and efficiency stand as the cornerstones of success. Among the many techniques that have transformed the landscape of production, metal stamping takes a prominent place. At the heart of this process lies the metal stamping die, an essential tool that shapes raw metal into intricate forms with unparalleled accuracy. Behind these remarkable dies are the skilled craftsmen and innovative manufacturers dedicated to pushing the boundaries of possibility.

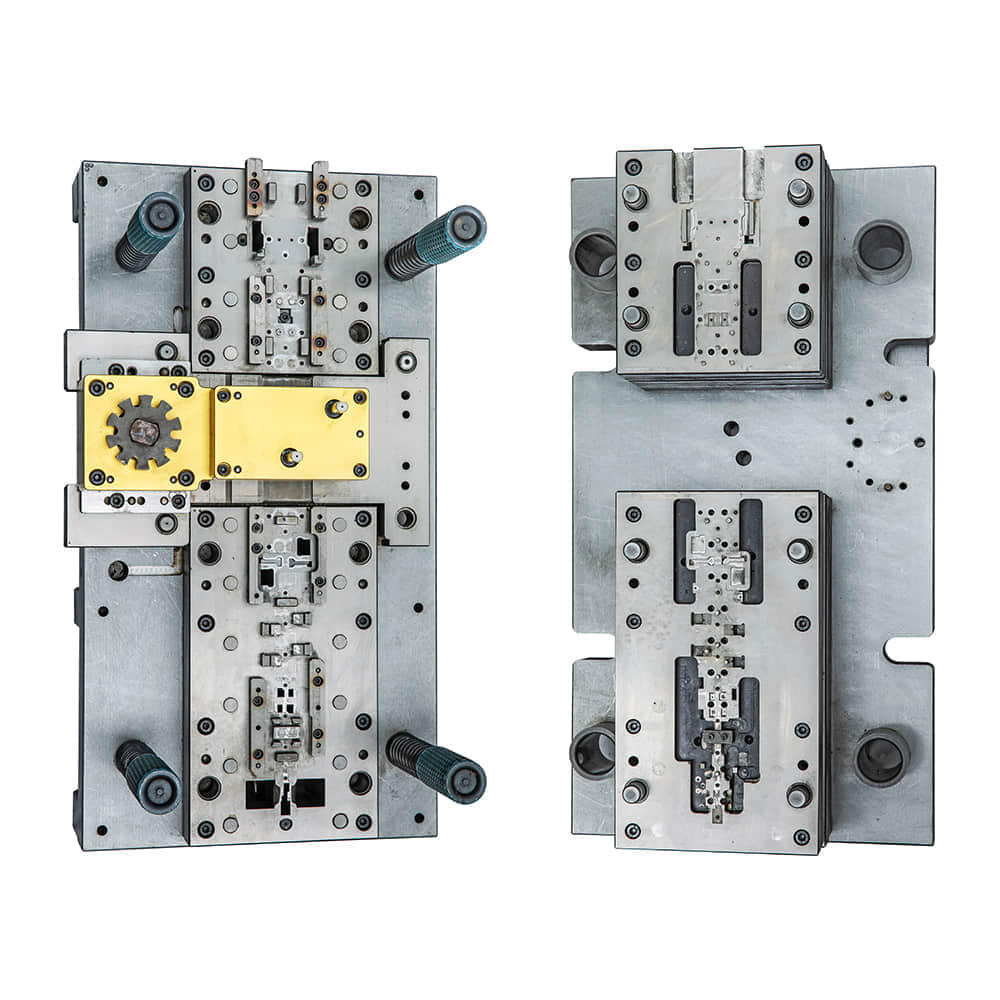

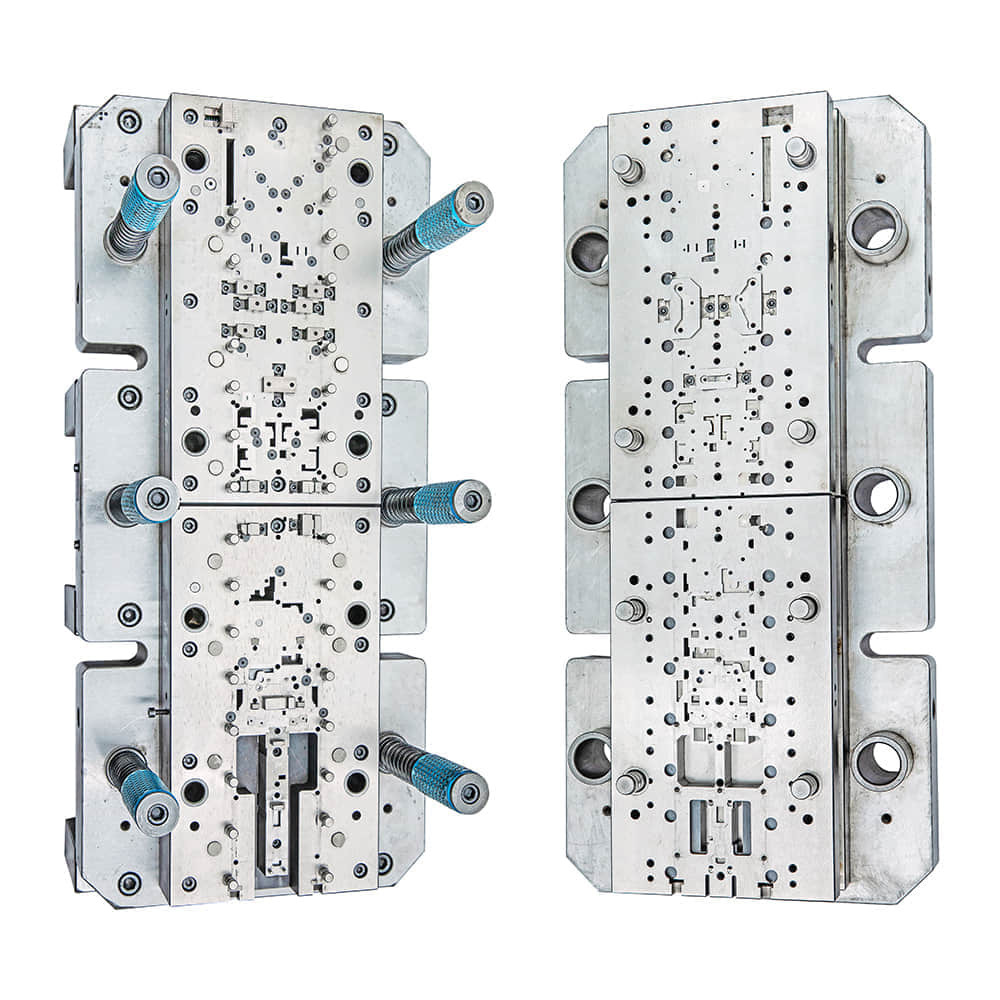

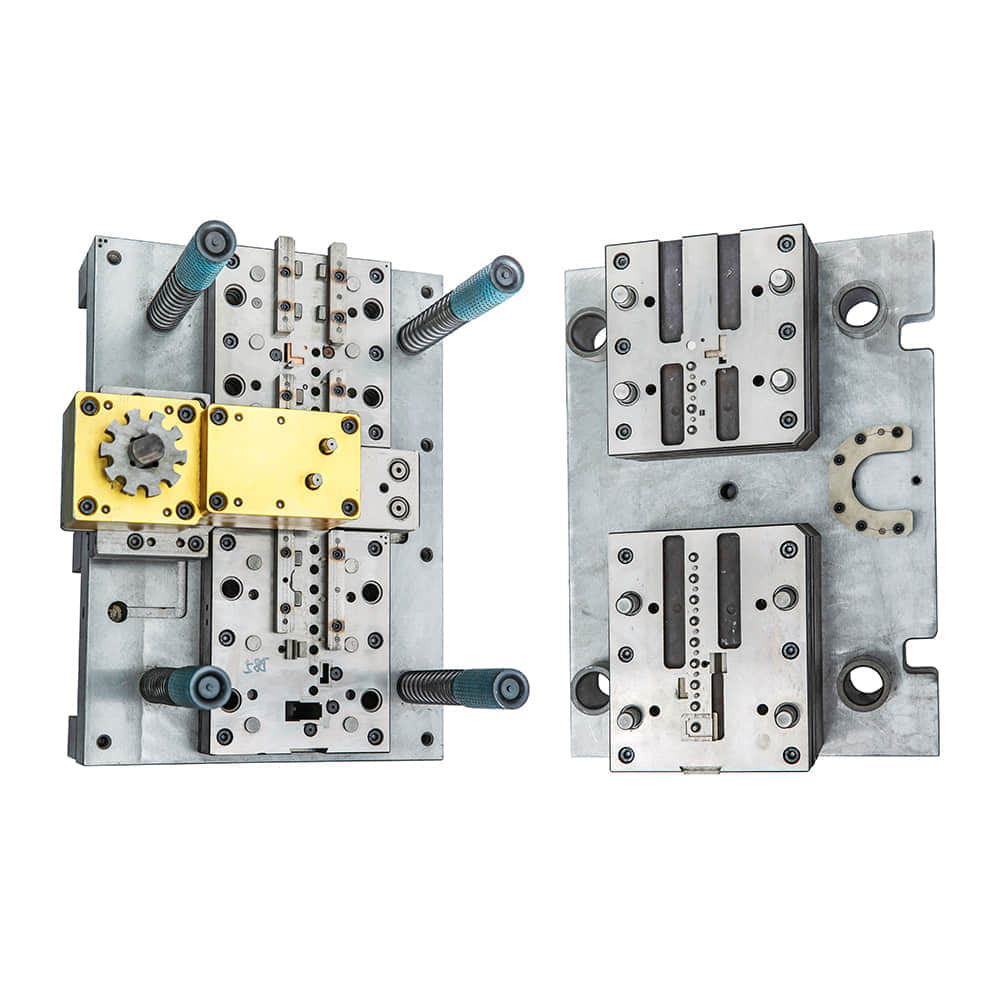

A metal stamping die is not merely a tool; it is a culmination of engineering, artistry, and technological prowess. Manufacturers in this specialized field blend traditional craftsmanship with cutting-edge techniques to produce dies that shape the products we rely on daily. The process begins with the meticulous design of the die, where engineers harness computer-aided design (CAD) software to create a blueprint of unparalleled precision. Every contour, every angle, and every detail is carefully calculated, ensuring that the end product meets exact specifications.

Once the design phase is complete, the skilled hands of craftsmen take over. The raw materials, often high-strength steel, are sculpted with unwavering attention to detail. The level of precision required demands not only technical expertise but also an artistic touch. Craftsmen meticulously carve, shape, and assemble the die components, often relying on decades of experience to bring the design to life. It’s in these moments that a simple piece of metal transforms into a tool that will define manufacturing processes. In recent years, technological advancements have brought new dimensions to the art of metal stamping die manufacturing. Computer Numerical Control (CNC) machining has streamlined production, allowing for unprecedented levels of intricacy. CNC machines, guided by the original CAD design, sculpt the die components with microscopic precision. This marriage of human skill and technological precision results in dies that can shape products with tolerances as small as a fraction of a millimeter. The applications of metal stamping dies are diverse and vital across various industries. From automotive parts that ensure our vehicles run smoothly, to intricate electronic components that power our devices, these dies form the backbone of modern manufacturing. This level of significance places immense responsibility on the shoulders of manufacturers. Flawless reliability isn’t just a goal; it’s a necessity. Furthermore, the commitment of metal stamping die manufacturers extends beyond the production floor. As sustainability and environmental consciousness take center stage, manufacturers are exploring ways to minimize waste, reduce energy consumption, and optimize the use of resources. By implementing eco-friendly practices, the industry is ensuring that precision and responsibility go hand in hand. In conclusion, the realm of metal stamping die manufacturing is a testament to human ingenuity and dedication. It’s where science, art, and technology unite to shape the products that define our modern lives. With unwavering precision, skilled craftsmen and innovative manufacturers continue to push the boundaries of what’s possible, ensuring that the tools of today are as exceptional as the products they help create.