Injection molding has revolutionized the world of manufacturing with its precision, efficiency, and versatility. It has become an essential process in various industries, from automotive to consumer electronics, producing everything from intricate components to everyday items. In this article, we will delve into the world of injection molded parts, exploring their manufacturing process, applications, and the advantages they offer.

The Injection Molding Process

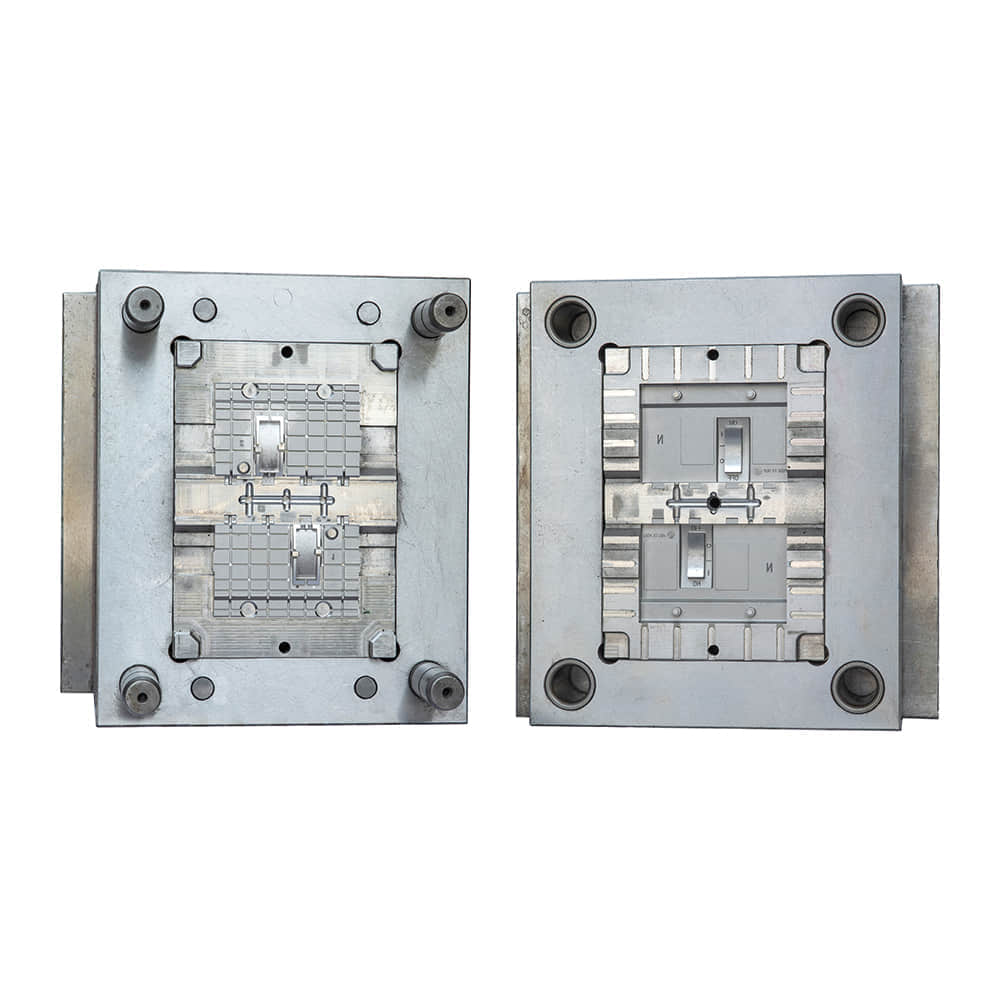

Injection molding is a manufacturing technique that involves injecting molten material, typically plastic, into a mold cavity. Once the material cools and solidifies, it takes on the shape of the mold, resulting in a finished product. This process is highly repeatable and allows for the production of complex parts with tight tolerances. Material Preparation: The process begins with the selection of a suitable thermoplastic material. The chosen material is then melted and prepared for injection. Injection: The molten material is injected into a mold cavity under high pressure. This pressure ensures that the material fills the entire cavity, capturing all the intricate details of the part. Cooling: After injection, the mold is cooled to solidify the material. The cooling process is critical, as it determines the part’s final properties and dimensions. Ejection: Once the material has solidified, the mold opens, and the finished part is ejected. The cycle then repeats for the next part. Applications of Injection Molded Parts Injection molded parts find applications in a wide range of industries, owing to their versatility and precision. Some common applications include: Automotive Industry: Injection molded parts are used in car interiors, exteriors, and under the hood. They provide lightweight, durable solutions for components such as dashboards, bumpers, and engine covers. Consumer Electronics: From smartphone cases to laptop housings, injection molded parts play a vital role in the consumer electronics industry. They offer a sleek and protective exterior for these devices. Medical Devices: Many critical medical devices are made using injection molding, ensuring precision and biocompatibility. These include syringes, IV connectors, and even prosthetic components. Packaging: Plastic bottles, caps, and closures are often produced through injection molding, offering a cost-effective and reliable solution for packaging needs. Toys and Games: The toy industry relies heavily on injection molding for producing action figures, game pieces, and various other toys. The process allows for the creation of intricate designs and vibrant colors. Advantages of Injection Molded Parts The popularity of injection molded parts can be attributed to several key advantages: Precision: Injection molding offers exceptional dimensional accuracy and repeatability. Parts can be produced with tight tolerances, ensuring a perfect fit in assemblies. Efficiency: The high-speed nature of the process, along with the ability to create multiple cavities within a single mold, results in efficient and cost-effective production. Versatility: Injection molding accommodates a wide range of materials, colors, and finishes. It can produce parts ranging from small, intricate components to large, structural pieces. Reduced Waste: The process generates minimal waste, as excess material can often be reground and reused in subsequent runs. Durability: Injection molded parts are known for their durability and resistance to wear, chemicals, and environmental factors. Conclusion Injection molded parts have become a cornerstone of modern manufacturing. Their precision, efficiency, and versatility make them indispensable in a wide array of industries, shaping everything from our vehicles to our electronic devices. As technology continues to advance, we can expect injection molding to play an even more significant role in the production of high-quality, precision-engineered components that drive innovation and improve our everyday lives.