Introduction

In the realm of modern manufacturing, thermoplastic injection molds have emerged as a transformative technology, enabling the creation of intricate and high-quality plastic components. This method, widely employed across industries, offers remarkable advantages in terms of precision, efficiency, and material versatility. In this article, we delve into the world of thermoplastic injection molds, exploring their key features, applications, and the technological advancements that continue to shape their evolution.

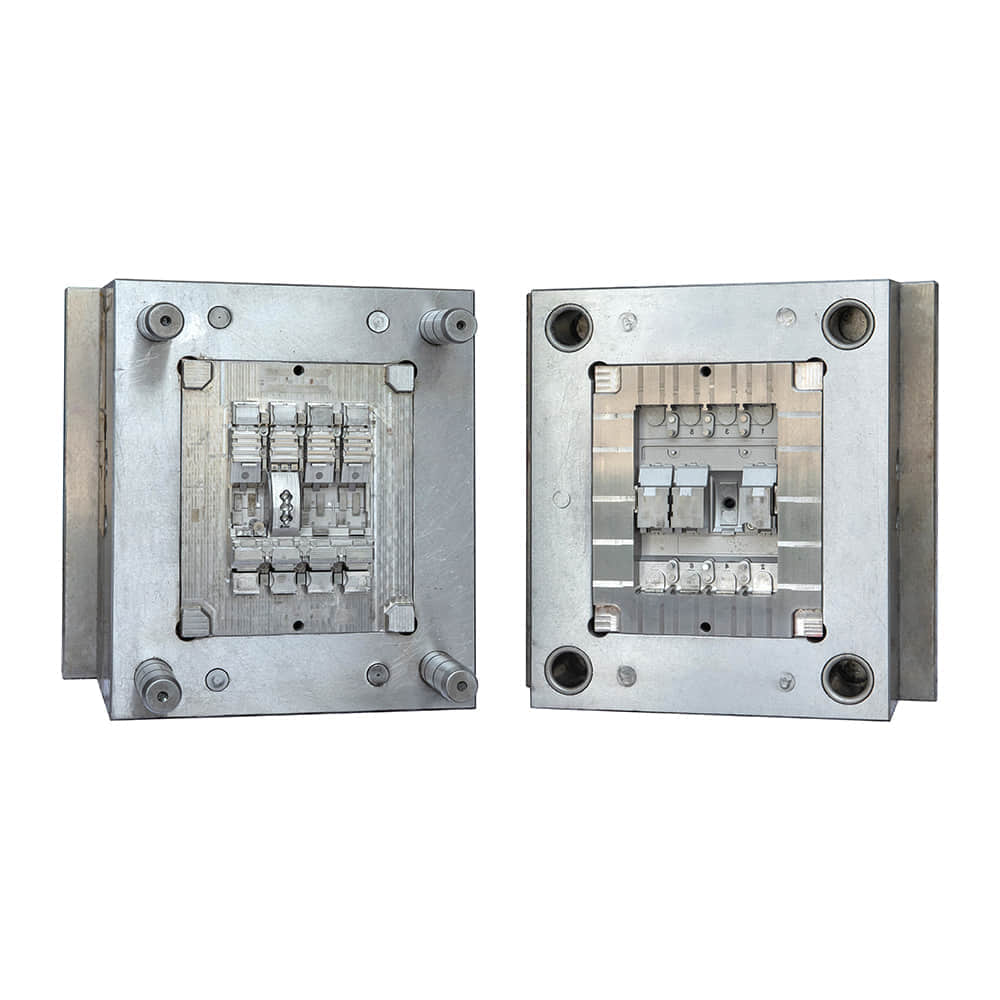

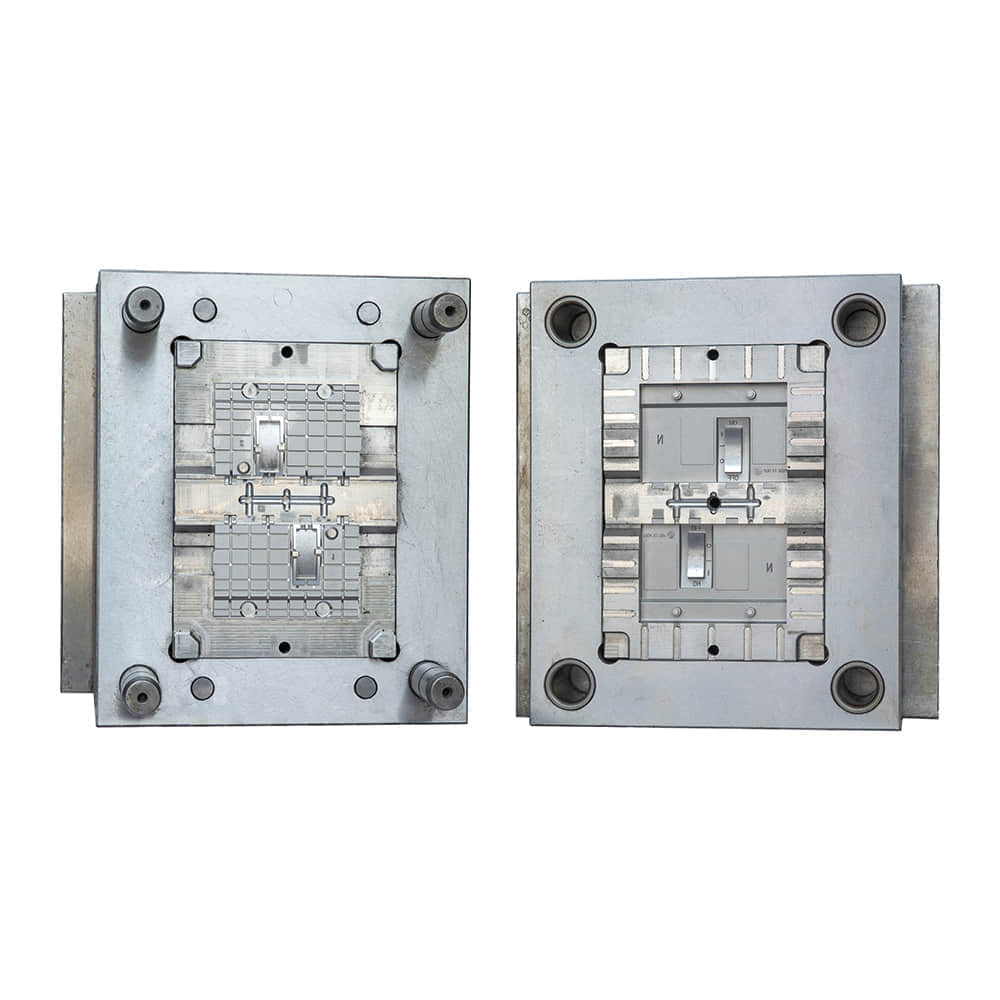

The Basics of Thermoplastic Injection Molds Thermoplastic injection molding is a manufacturing process that involves injecting molten thermoplastic material into a mold cavity, allowing it to cool and solidify into the desired shape. This process is highly automated and can produce a wide range of products, from intricate gears to large automotive parts. The molds themselves are precision-engineered tools, often made from steel or aluminum, with intricate cavities that define the final product’s geometry. Advantages and Applications The utilization of thermoplastic injection molds offers numerous advantages that have contributed to its widespread adoption. Firstly, it enables the production of complex and intricate designs with exceptional accuracy and repeatability. This makes it an ideal choice for industries such as electronics, where miniaturization is a constant demand. Secondly, the process is highly efficient, with rapid cycle times allowing for high-volume production. This efficiency not only reduces manufacturing costs but also promotes sustainability by minimizing material waste. Additionally, the ability to use a wide range of thermoplastic materials enhances the versatility of the process, making it suitable for applications across industries, including automotive, consumer goods, medical devices, and more. Technological Advancements Recent years have witnessed significant technological advancements in the field of thermoplastic injection molds. One such development is the integration of sensor technology and real-time monitoring systems. These innovations allow manufacturers to closely monitor factors like temperature, pressure, and flow rates during the injection process. Such insights enable process optimization, early detection of potential defects, and overall quality enhancement. Furthermore, the emergence of computer simulations and advanced modeling techniques has revolutionized mold design and testing. Engineers can now simulate the entire injection molding process virtually, predicting how different materials and design elements will interact. This not only expedites the design phase but also contributes to the development of more robust and efficient molds. In line with the industry’s move towards sustainability, there has also been a push for more eco-friendly materials and practices. Biodegradable and recycled thermoplastics are being integrated into injection molding processes, addressing environmental concerns without compromising product quality. Challenges and Future Prospects While thermoplastic injection molds offer numerous advantages, challenges persist. Designing intricate molds can be time-consuming and costly, requiring skilled professionals and advanced machinery. Moreover, as designs become more complex, ensuring uniform cooling throughout the mold becomes crucial to prevent defects. Looking ahead, the future of thermoplastic injection molds appears promising. Advances in materials science, automation, and process monitoring are likely to address current challenges. The integration of artificial intelligence and machine learning could further optimize the injection molding process by predicting and preventing defects in real time. Conclusion Thermoplastic injection molds have undeniably transformed the landscape of modern manufacturing. Their ability to create intricate designs with high precision, efficiency, and material versatility makes them invaluable across various industries. With ongoing technological advancements, these molds are poised to become even more sophisticated and efficient, contributing to the creation of innovative and sustainable products in the years to come.