In the world of modern manufacturing, precision, efficiency, and innovation are paramount. Among the key players driving this progress is the Metal Stamping Die OEM Manufacturer. With a rich history rooted in craftsmanship and an unwavering commitment to excellence, these manufacturers play a pivotal role in shaping industries across the globe.

Crafting Precision Through Expertise

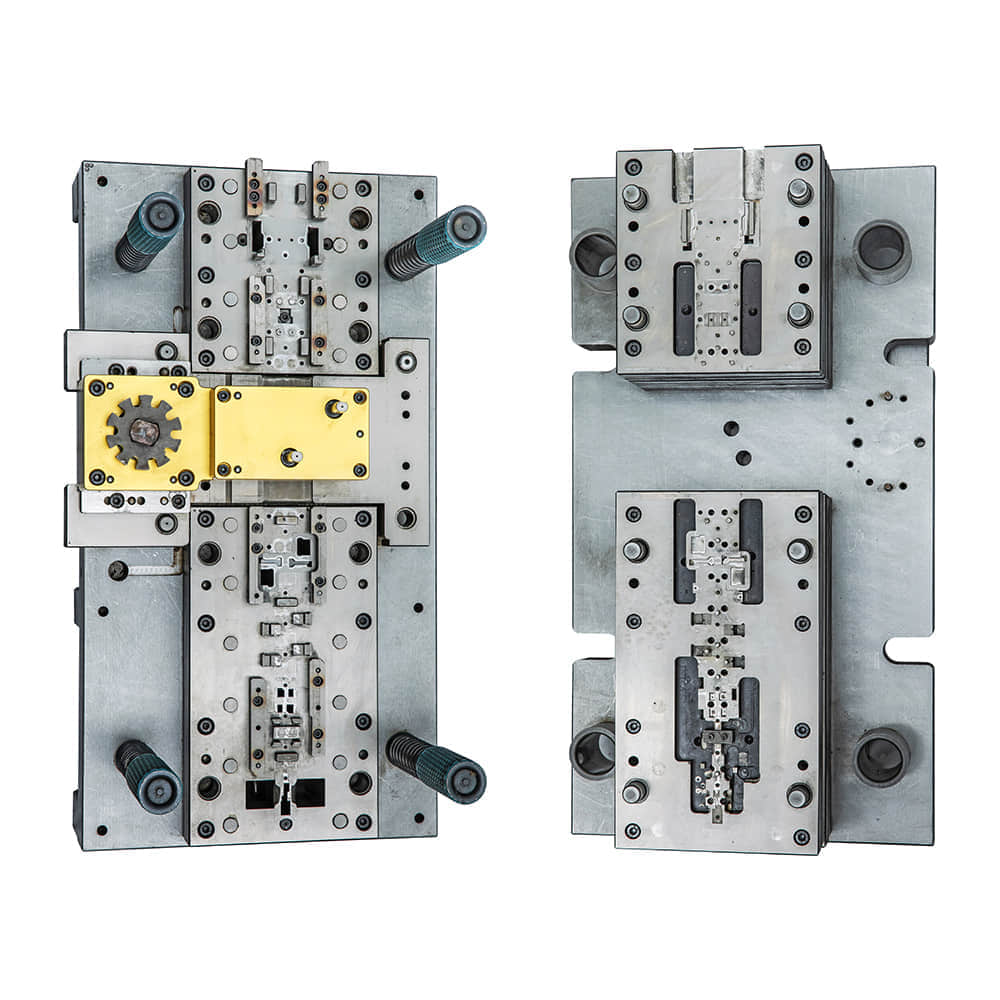

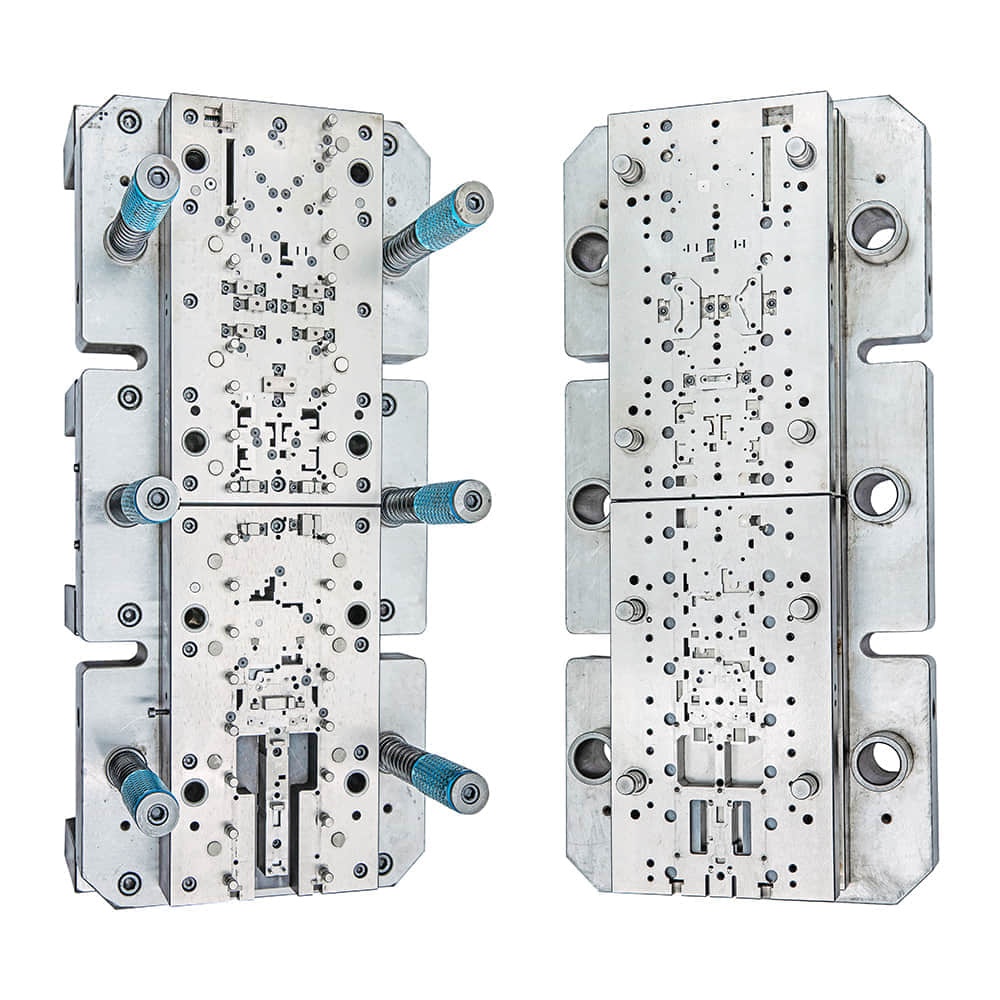

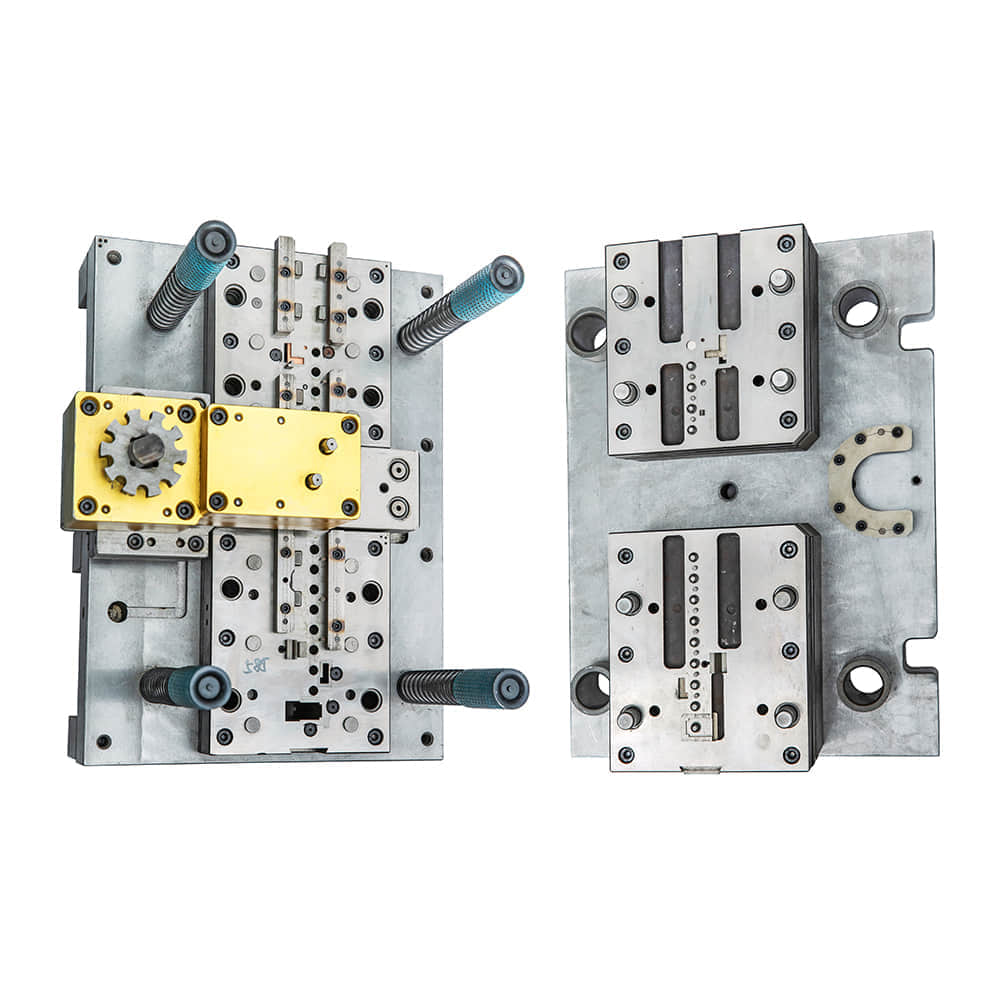

Metal stamping die OEM manufacturers are known for their expertise in creating intricate and specialized tools essential for producing high-quality metal parts. These dies, meticulously designed and engineered, are used in various industries such as automotive, electronics, aerospace, and more. The precision achieved in the manufacturing process is a testament to the manufacturer’s commitment to delivering flawless end products. The process begins with a thorough analysis of the client’s requirements. Engineers collaborate closely with clients to understand their needs, material specifications, and desired outcomes. This collaborative approach ensures that the resulting metal stamping dies are tailored to exact specifications. Innovation: Paving the Path to Progress Innovation is the beating heart of Metal Stamping Die OEM Manufacturers. The relentless pursuit of better solutions drives these manufacturers to stay at the forefront of technological advancements. From integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) software to adopting state-of-the-art manufacturing techniques, these companies continuously push the boundaries of what is possible. One notable innovation in recent years is the application of additive manufacturing, commonly known as 3D printing. Metal Stamping Die OEM Manufacturers have harnessed this technology to rapidly prototype and even manufacture certain types of stamping dies. This not only reduces lead times but also opens doors to creating complex geometries that were once considered challenging or impossible. Quality Control: Ensuring Excellence The reputation of Metal Stamping Die OEM Manufacturers hinges on the quality of their products. Rigorous quality control measures are embedded at every stage of the manufacturing process. Advanced testing methods, including computer simulations and physical prototypes, are employed to validate the design before production. During production, materials are carefully selected based on their properties and suitability for the intended application. The manufacturing process itself is closely monitored and optimized to minimize deviations from the design specifications. This meticulous attention to detail ensures that each stamped metal part meets the highest standards of quality and performance. Global Impact and Collaborative Growth Metal Stamping Die OEM Manufacturers have a global footprint, serving industries around the world. Their contributions are not limited to manufacturing alone; they often collaborate with clients to refine designs, explore cost-saving measures, and optimize production processes. This collaborative approach fosters a dynamic exchange of ideas and expertise, resulting in mutual growth and innovation. Conclusion In the realm of modern manufacturing, Metal Stamping Die OEM Manufacturers stand as beacons of precision, innovation, and quality. Their expertise in crafting intricate metal stamping dies, coupled with a relentless pursuit of innovation, has enabled industries to achieve new heights of efficiency and excellence. As technology continues to advance, we can only anticipate that these manufacturers will lead the way, shaping the future of manufacturing one precise stamp at a time.