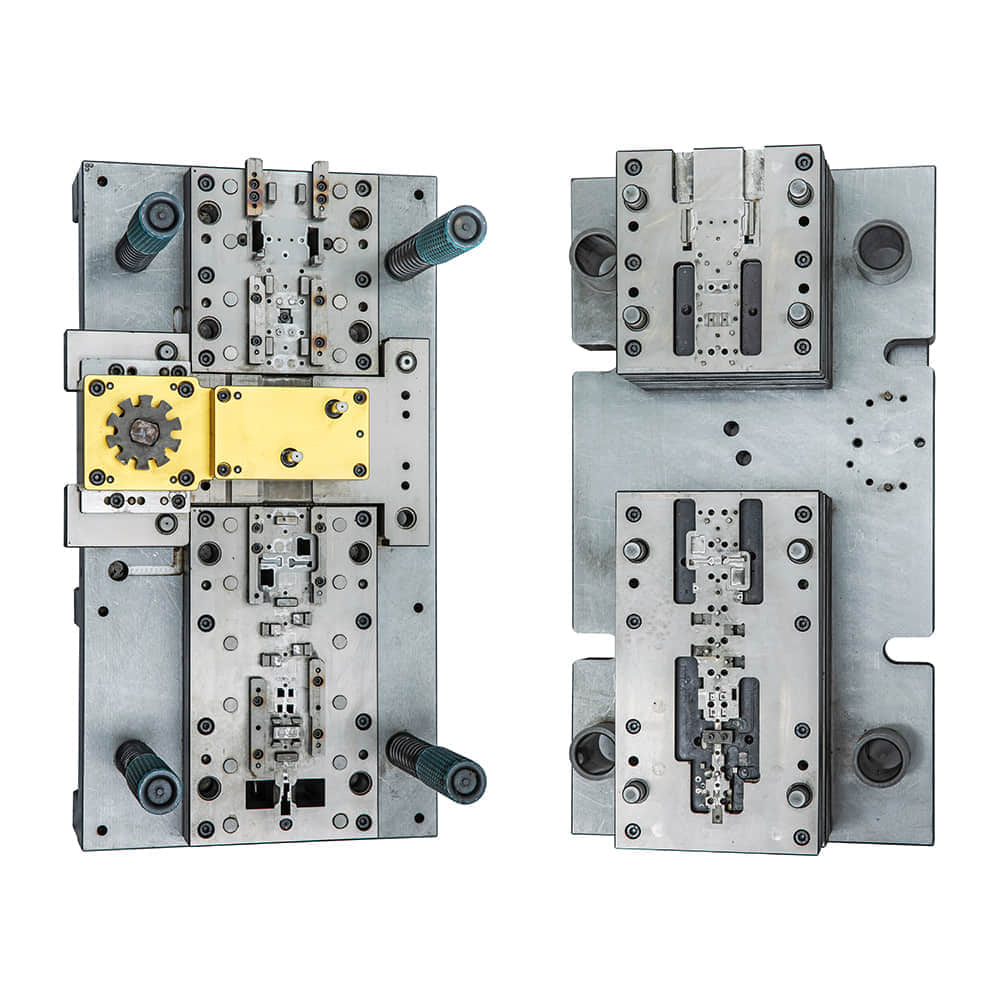

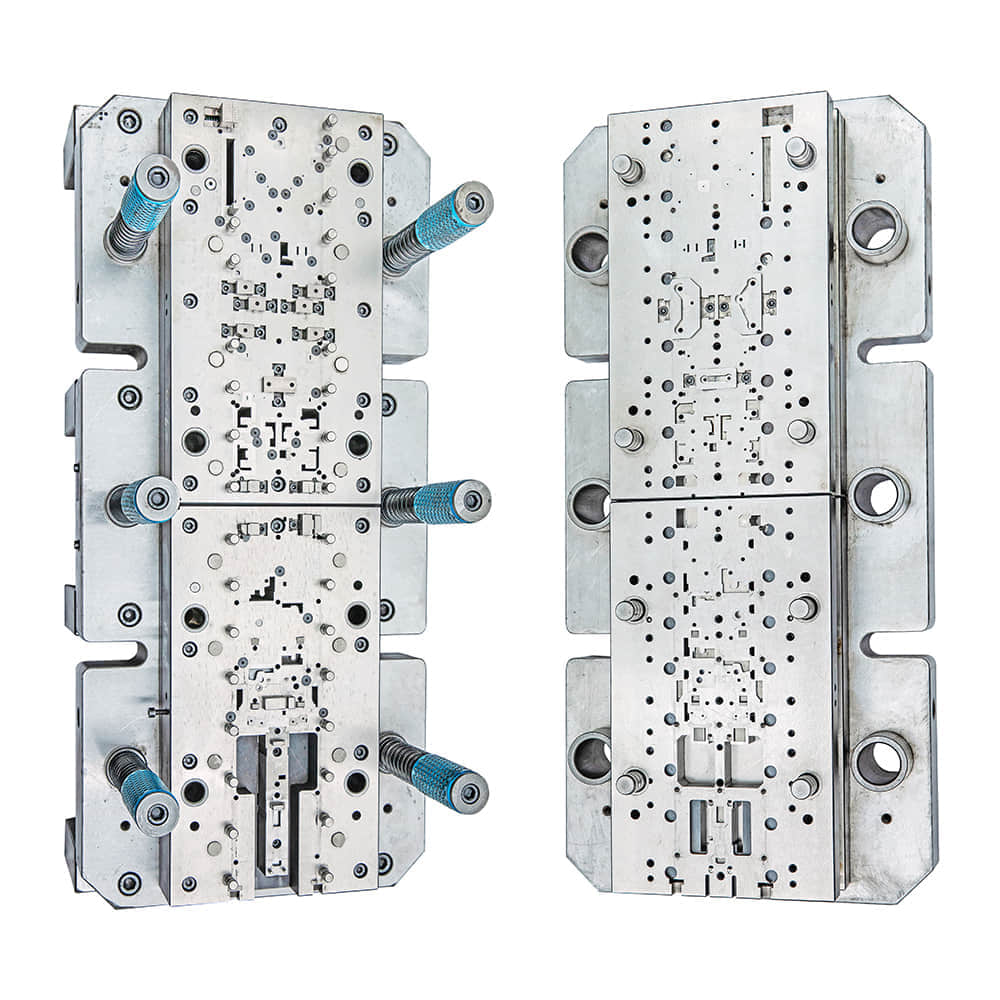

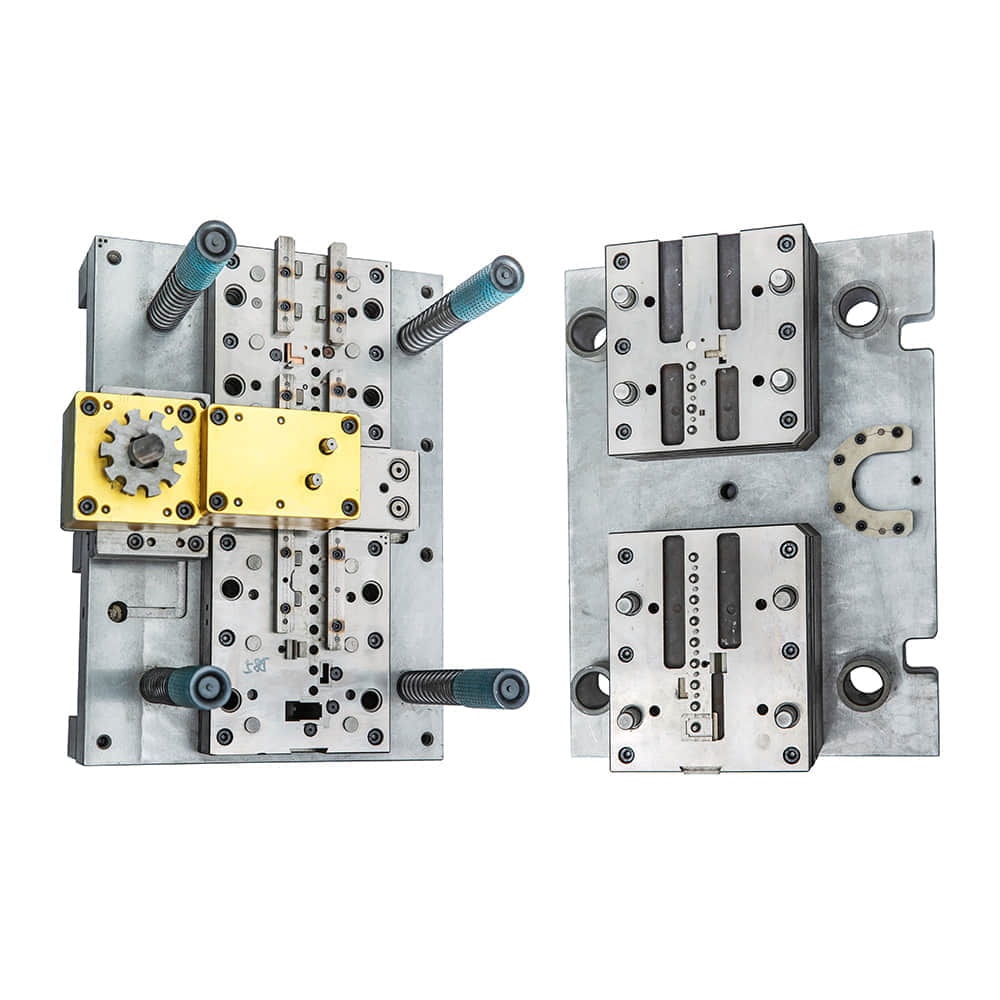

Blanking dies are an indispensable tool in the world of manufacturing and metalworking. These intricate pieces of equipment play a crucial role in shaping various materials into specific forms, contributing to the creation of countless products that we encounter daily. From automotive components to consumer electronics, the functionality of blanking dies remains unparalleled. In this article, we delve into the world of blanking dies, exploring their design, applications, and significance in modern manufacturing.

The Art of Blanketing Dies Design

At the heart of every successful blanking process lies a meticulously designed blanking die. A blanking die is essentially a specialized cutting tool used to shear or punch out intricate shapes from a sheet of material, often metal. The design of the die is a blend of engineering precision and creativity. Engineers must consider factors like material type, thickness, shape complexity, and production volume to craft a die that not only performs flawlessly but also maximizes efficiency. Blanking dies come in various types, such as simple blanking dies, compound dies, and progressive dies. Simple blanking dies are used for basic shapes, while compound and progressive dies are employed for more complex and intricate patterns. These designs require careful planning to ensure that the material is cut accurately and efficiently, minimizing waste and ensuring consistent results. Applications Across Industries The applications of blanking dies are extensive, spanning across industries that range from automotive to electronics and beyond. In the automotive sector, blanking dies are responsible for crafting intricate parts like gears, clutches, and engine components. These dies play a crucial role in shaping metal sheets into components that meet stringent standards for safety, precision, and durability. In the electronics industry, blanking dies are equally vital. They are utilized in the production of smartphone components, computer parts, and even delicate connectors. The precision offered by blanking dies ensures that these tiny components are manufactured with consistent quality, facilitating the assembly and performance of complex electronic devices. Significance in Modern Manufacturing The significance of blanking dies in modern manufacturing cannot be overstated. These dies enable mass production of intricate parts with minimal errors. The accuracy and repeatability they offer streamline the production process, leading to cost savings and improved product quality. Moreover, the versatility of blanking dies contributes to the diversity of products that can be manufactured. From large automobile components to tiny medical device parts, blanking dies can be customized to accommodate a wide range of shapes and sizes. This adaptability is a cornerstone of modern manufacturing, allowing industries to respond to market demands swiftly. Advancements in Blanketing Dies Technology As technology continues to evolve, so do blanking dies. Advanced computer simulations and modeling techniques allow engineers to test and refine die designs virtually before physical production begins. This reduces the trial-and-error phase, leading to faster development cycles and greater precision. Additionally, automation has transformed the blanking process. Automated presses equipped with sophisticated control systems can execute complex blanking operations with minimal human intervention. This not only enhances the safety of the manufacturing environment but also improves efficiency and reduces labor costs. The Future of Blanking Dies Looking ahead, the future of blanking dies appears promising. As industries demand more intricate and specialized components, blanking dies will need to keep pace. This will likely lead to further advancements in die design, materials, and manufacturing processes. Moreover, the integration of artificial intelligence and data analytics could revolutionize blanking die optimization, enabling predictive maintenance and real-time performance monitoring. In conclusion, blanking dies are the unsung heroes of modern manufacturing. Their intricate design, diverse applications, and contribution to efficiency make them an essential tool across various industries. As technology continues to advance, blanking dies will evolve as well, shaping the products of tomorrow with unmatched precision and innovation.