China Metal Stamping Die Manufacturers: Crafting Precision and Innovation

China has emerged as a global powerhouse in manufacturing, with a reputation for producing high-quality products across various industries. In the realm of metal stamping, the country’s manufacturers have carved a niche for themselves, becoming leaders in crafting precision and innovation through metal stamping dies.

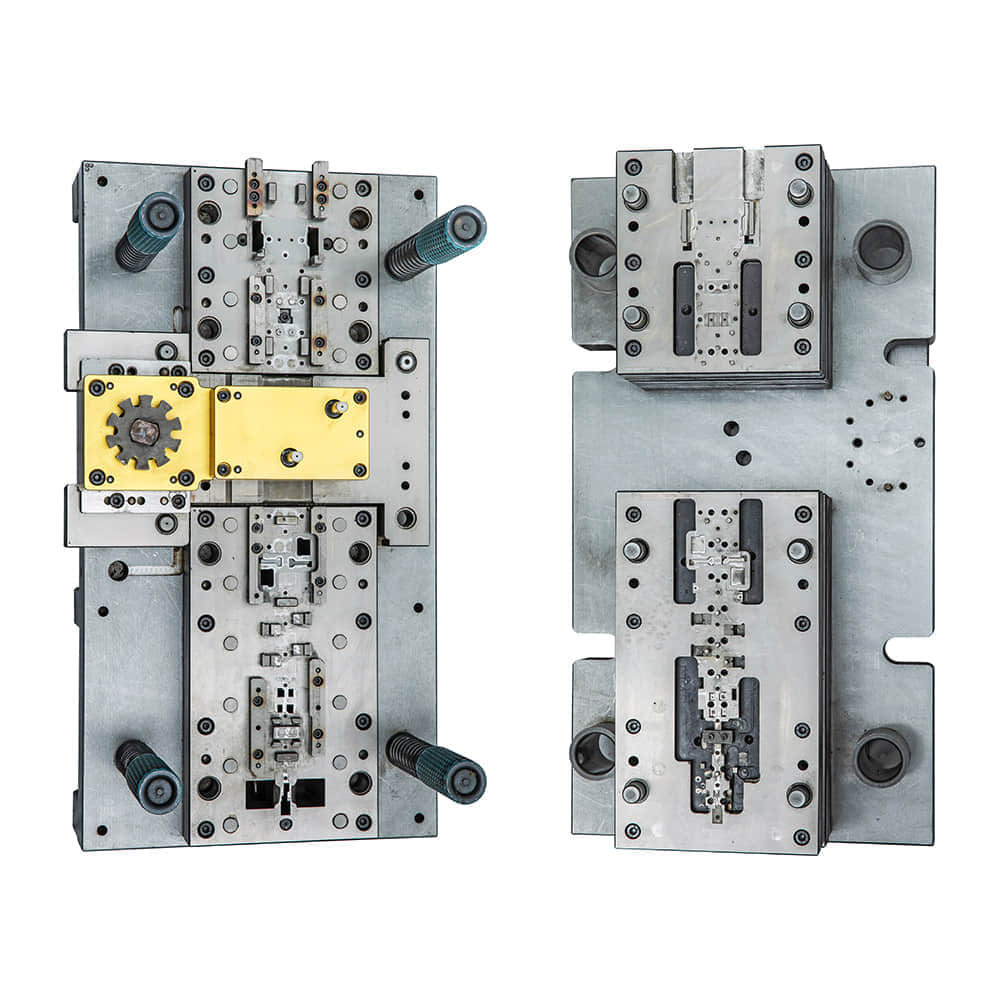

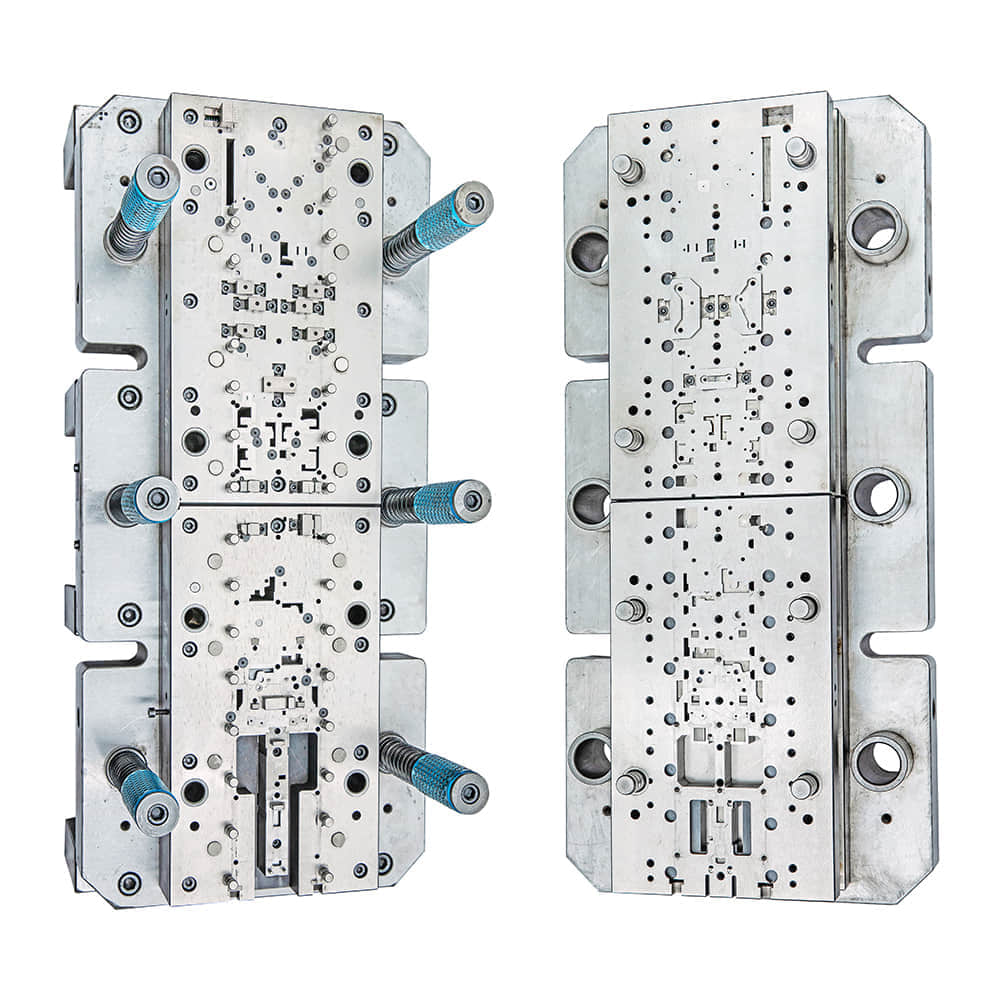

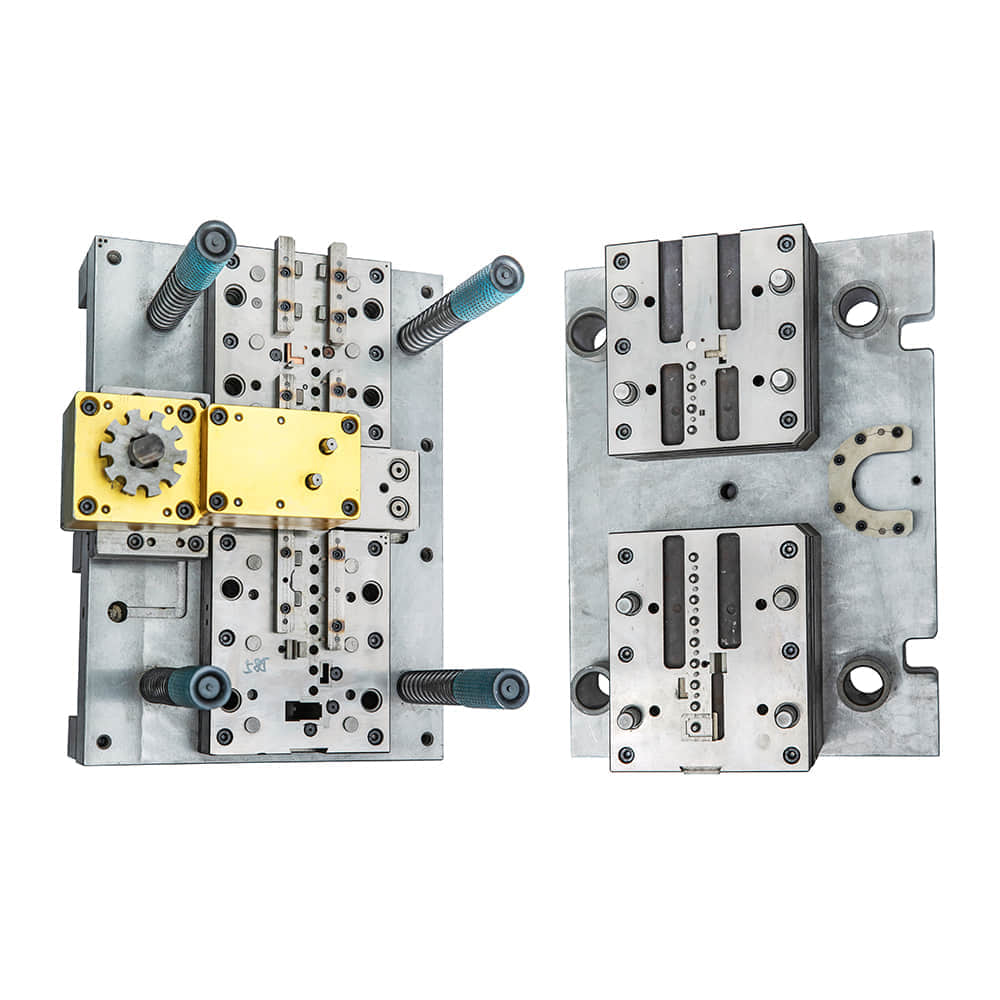

The Foundation of Excellence Metal stamping, a manufacturing process that involves shaping, cutting, or forming metal sheets, relies heavily on the quality and precision of the stamping dies. These dies are essentially specialized tools that transform raw metal materials into intricate components used in industries ranging from automotive to electronics. China’s metal stamping die manufacturers are built on a foundation of excellence. They invest heavily in research and development, employing cutting-edge technologies to design and produce dies that meet the most stringent quality standards. With a focus on precision engineering, these manufacturers have gained a competitive edge, attracting customers worldwide. Advanced Manufacturing Techniques China’s metal stamping die manufacturers leverage advanced manufacturing techniques to create dies that are not only precise but also highly efficient. Computer Numerical Control (CNC) machining, for instance, is widely employed to ensure every cut and shape is executed with unparalleled accuracy. This precision guarantees that the end products are consistent and reliable, a crucial factor in industries like automotive and aerospace. Moreover, many Chinese manufacturers have embraced automation and robotics to streamline their production processes. This not only enhances efficiency but also reduces the margin of error, resulting in faster turnaround times and cost savings for clients. Innovation at the Core Innovation is the lifeblood of any industry, and China’s metal stamping die manufacturers understand this well. They continuously push the boundaries of what is possible, developing new techniques and materials to stay ahead of the competition. One area where innovation shines is in the use of high-strength and lightweight materials. As industries seek to reduce the weight of their products for improved fuel efficiency and performance, metal stamping dies are being designed to work with materials such as aluminum and advanced alloys. China’s manufacturers are at the forefront of these innovations, providing solutions that cater to evolving industry needs. Global Reach and Customer-Centric Approach China’s metal stamping die manufacturers have a global reach, with products exported to countries around the world. This international presence speaks to the quality and reliability of their products. They work closely with customers, understanding their unique requirements and challenges, and tailor their solutions accordingly. Customer satisfaction is a top priority for these manufacturers. They offer comprehensive support, from design consultation to after-sales service, ensuring that clients receive the best possible value. This customer-centric approach has earned them a solid reputation in the global market. Sustainability and Environmental Responsibility In recent years, environmental sustainability has become a critical concern in manufacturing. China’s metal stamping die manufacturers have responded by adopting eco-friendly practices. They invest in technologies that minimize waste, reduce energy consumption, and promote recycling. By doing so, they not only contribute to a cleaner planet but also align with the sustainability goals of many of their customers. Conclusion China’s metal stamping die manufacturers have risen to prominence by upholding the highest standards of quality, precision, and innovation. Their commitment to excellence, coupled with a customer-centric approach and a focus on sustainability, has made them trusted partners in industries worldwide. As they continue to evolve and push the boundaries of what is possible, they remain at the forefront of metal stamping technology, shaping the future of manufacturing.