Thermoplastic injection molding has revolutionized the manufacturing industry by enabling the production of intricate and precise plastic components at scale. This technique involves injecting molten thermoplastic material into a mold cavity, allowing it to cool and solidify, resulting in the creation of a wide range of products. Over the years, significant advancements in both materials and techniques have contributed to enhancing the efficiency, precision, and sustainability of thermoplastic injection molds.

1. Evolution of Thermoplastic Materials

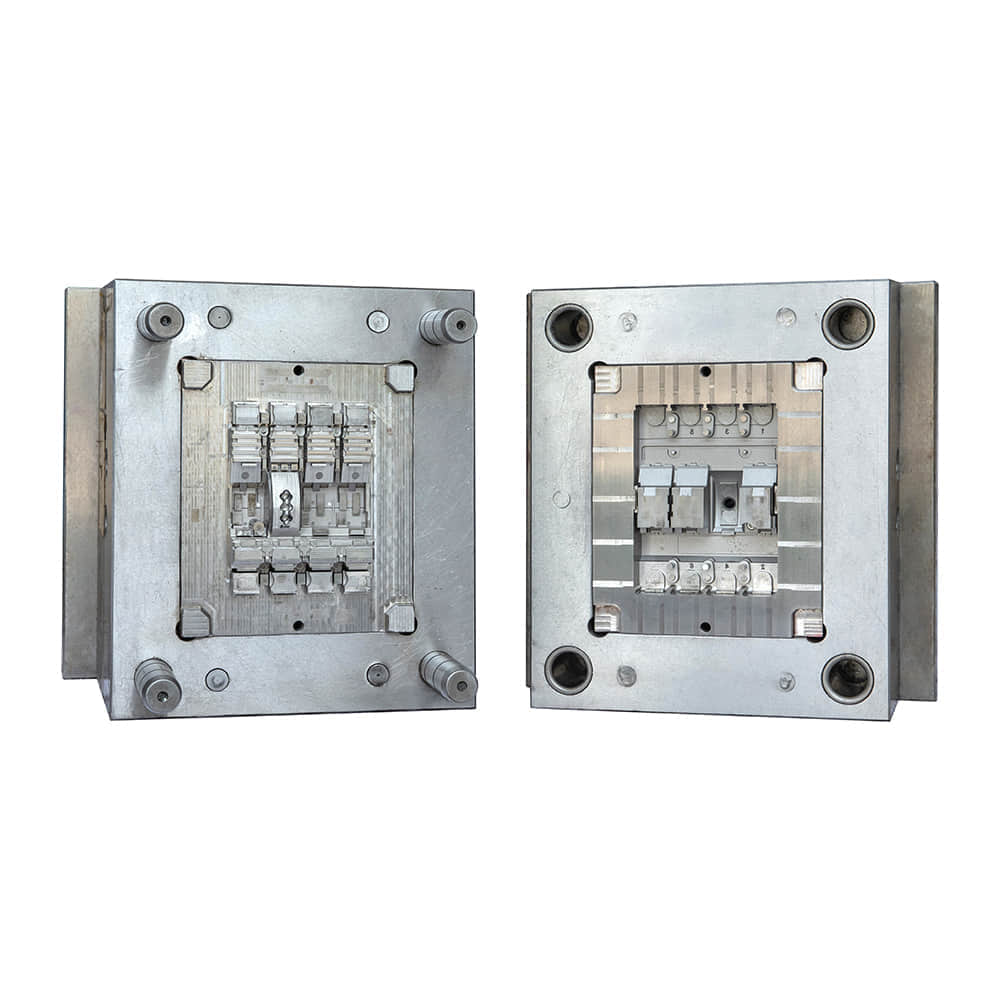

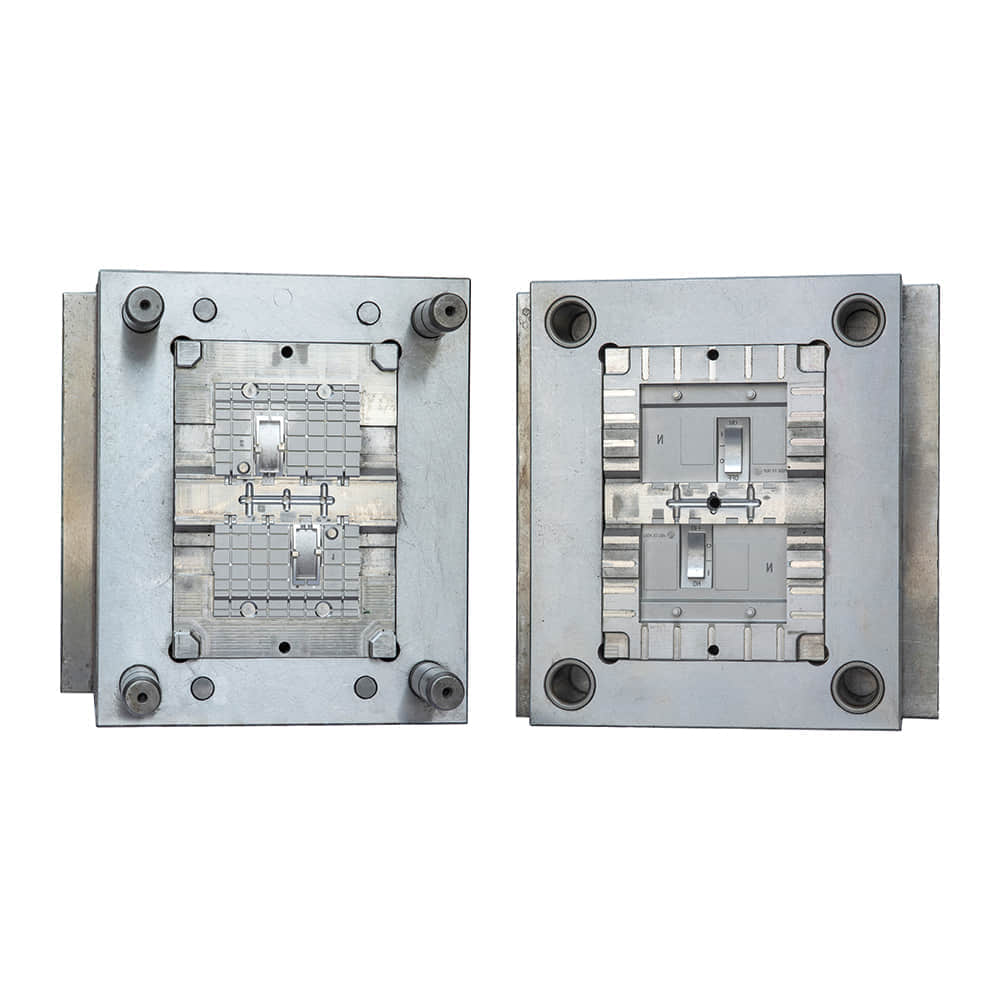

One of the driving forces behind the success of thermoplastic injection molding is the continuous development of new and improved thermoplastic materials. These materials exhibit a remarkable combination of characteristics, including durability, flexibility, and resistance to heat and chemicals. Manufacturers can now choose from a diverse array of thermoplastics, each tailored to specific application requirements. From the commonly used polyethylene and polypropylene to engineering-grade plastics like polycarbonate and PEEK, the versatility of thermoplastics allows for the creation of products ranging from simple household items to complex medical devices. 2. Precision Engineering and Tooling Advancements in precision engineering and tooling have significantly refined the injection molding process. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies enable the creation of intricate mold designs with micron-level accuracy. High-precision machining techniques, such as Electrical Discharge Machining (EDM) and laser machining, ensure that molds are manufactured to exact specifications. This level of precision results in consistent product quality and reduces the need for post-production modifications. 3. Automation and Industry 4.0 Integration Automation has played a pivotal role in optimizing the thermoplastic injection molding process. Modern injection molding machines are equipped with robotic systems that handle tasks such as material loading, part ejection, and quality inspection. This not only improves production efficiency but also reduces the risk of defects caused by human error. Furthermore, the integration of Industry 4.0 principles allows for real-time monitoring of various process parameters. This data-driven approach enables manufacturers to make informed decisions, predict maintenance needs, and minimize downtime. 4. Sustainability and Circular Economy In recent years, there has been a growing emphasis on sustainability in the manufacturing sector. Thermoplastic injection molding aligns well with the principles of the circular economy due to the recyclability of thermoplastic materials. Manufacturers are exploring ways to use recycled thermoplastics in their injection molding processes, reducing the consumption of virgin materials and minimizing waste. Additionally, the energy-efficient nature of injection molding, coupled with advancements in energy-saving technologies, contributes to a greener manufacturing process. 5. Design Freedom and Complex Geometries The versatility of thermoplastic injection molding extends to the realm of design. Complex part geometries that were once deemed unfeasible can now be realized through advanced mold design techniques. Features like undercuts, thin walls, and intricate surface textures can be achieved with precision. This design freedom is particularly valuable in industries such as automotive, aerospace, and consumer electronics, where functional and aesthetic considerations are equally important. 6. Future Prospects As technology continues to evolve, the future of thermoplastic injection molding holds even more promise. Advancements in materials science may lead to the development of novel thermoplastics with enhanced properties, further expanding the range of applications. The integration of artificial intelligence and machine learning could optimize process parameters in real-time, pushing the boundaries of efficiency and quality. Furthermore, additive manufacturing techniques might complement traditional injection molding, enabling rapid prototyping and customization. In conclusion, the field of thermoplastic injection molding has undergone remarkable advancements, revolutionizing the way products are manufactured. From the evolution of materials to the integration of automation and sustainable practices, the industry has continuously pushed boundaries. With an eye on precision, sustainability, and innovation, thermoplastic injection molding is poised to shape the future of manufacturing in profound ways.