Introduction

In the realm of modern manufacturing, thermoplastic injection molds have emerged as a cornerstone technology. The utilization of thermoplastics in various industries has led to the refinement and innovation of injection molding processes. This article delves into the intricacies of thermoplastic injection molds, highlighting their significance, advancements, and impact on diverse sectors.

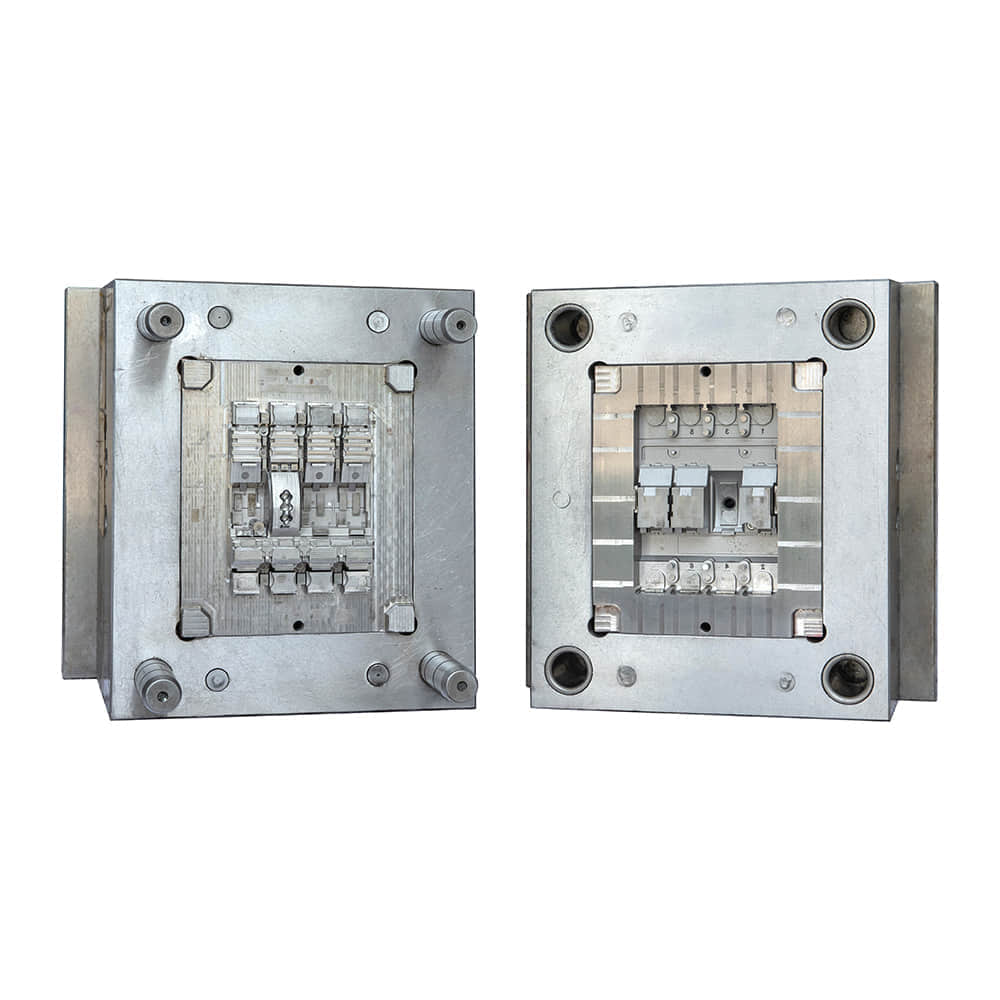

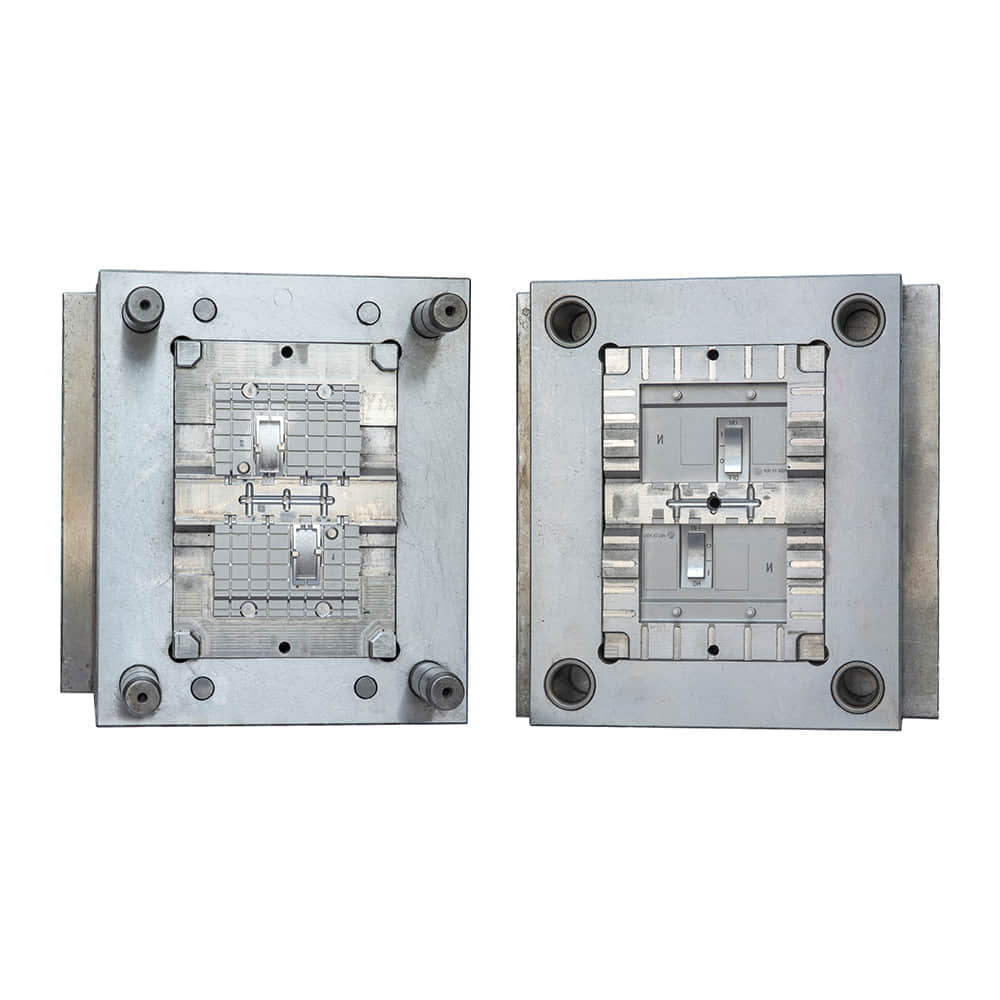

The Significance of Thermoplastic Injection Molds Thermoplastic injection molds play a pivotal role in transforming raw thermoplastic materials into intricate and functional products. This process involves the heating of thermoplastic pellets until they liquefy, injecting the molten material into a mold cavity, and subsequently allowing it to solidify and take the desired shape. The versatility of this method enables the creation of an extensive array of products, ranging from simple consumer goods to complex medical devices and automotive components. Advancements in Material Science One of the primary drivers of innovation in thermoplastic injection molds is the continuous evolution of materials. Engineers and researchers have been working diligently to develop thermoplastics with enhanced properties, such as increased strength, heat resistance, and biodegradability. These advancements have broadened the scope of applications, allowing industries to produce items that were previously deemed unfeasible using traditional materials. Precision and Complexity Modern thermoplastic injection molds have witnessed remarkable improvements in terms of precision and complexity. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have revolutionized mold design and production. With the assistance of these tools, manufacturers can create molds with intricate geometries and precise details. This level of intricacy is particularly valuable in industries like electronics, where miniaturization is a constant demand. Efficiency and Sustainability Advancements in thermoplastic injection molds have not only focused on product quality but also on process efficiency and sustainability. The development of energy-efficient injection molding machines and optimized cooling systems has led to reduced cycle times and lower energy consumption. Additionally, the push for eco-friendly practices has driven the adoption of bioplastics and the exploration of recycling methods, making the entire process more environmentally sustainable. Industries Transformed The impact of thermoplastic injection molds extends across various industries. In the automotive sector, lightweight and durable thermoplastic components are replacing traditional metal parts, contributing to fuel efficiency and lower production costs. The medical field benefits from sterile and customizable thermoplastic medical devices that adhere to stringent regulations. Consumer goods manufacturers appreciate the cost-effectiveness and rapid production capabilities of injection molding, enabling them to meet market demands swiftly. Challenges and Future Prospects While advancements have been remarkable, challenges persist. Achieving uniform material distribution, reducing defects, and ensuring consistent quality remain focal points. Researchers are also exploring innovative molding techniques, such as micro-injection molding and multi-material overmolding, to expand the possibilities even further. Looking ahead, the future of thermoplastic injection molds appears promising. As technology continues to evolve, it is likely that we will witness further enhancements in material properties, mold designs, and manufacturing processes. The integration of artificial intelligence and machine learning could lead to predictive maintenance of molds, reducing downtime and optimizing production. Conclusion Thermoplastic injection molds have undeniably redefined the landscape of modern manufacturing. Their influence spans numerous industries and is felt in the products that surround us daily. With a commitment to innovation, sustainability, and quality, the advancements in thermoplastic injection molds pave the way for a future where the only limit to creation is imagination.