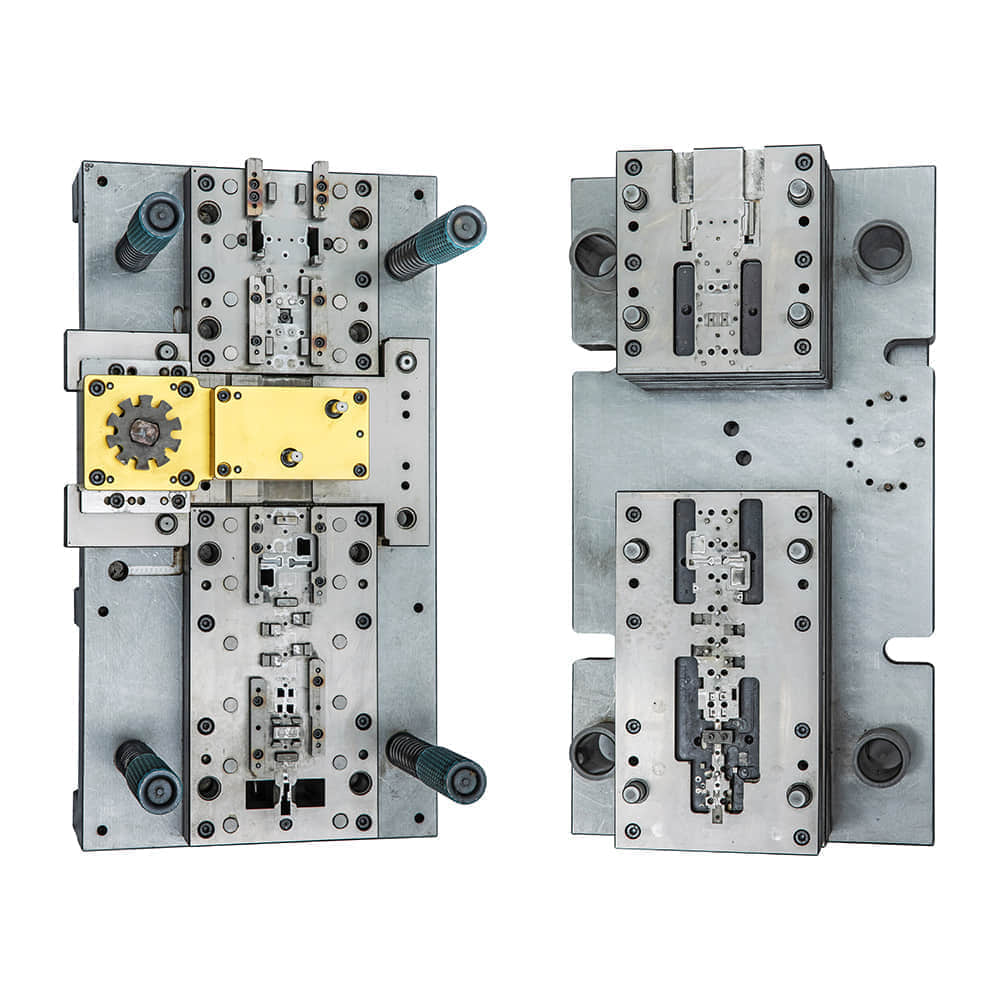

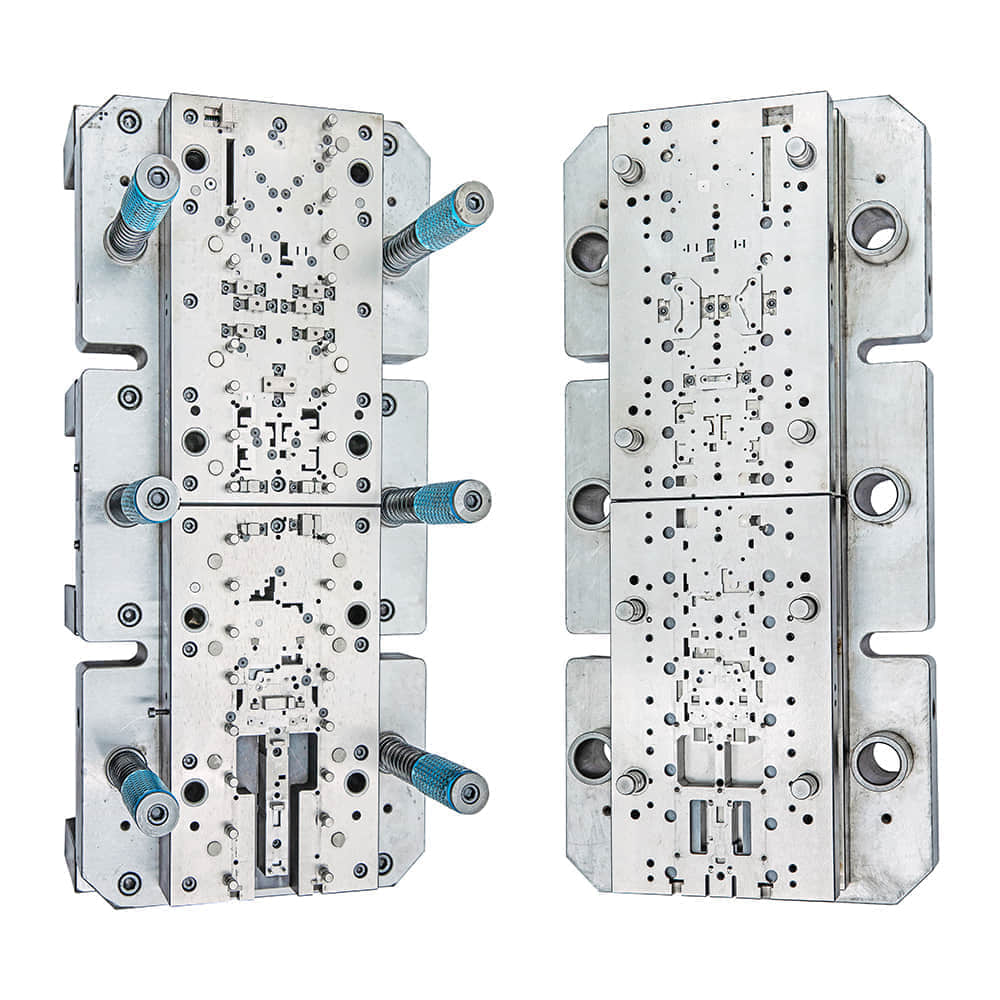

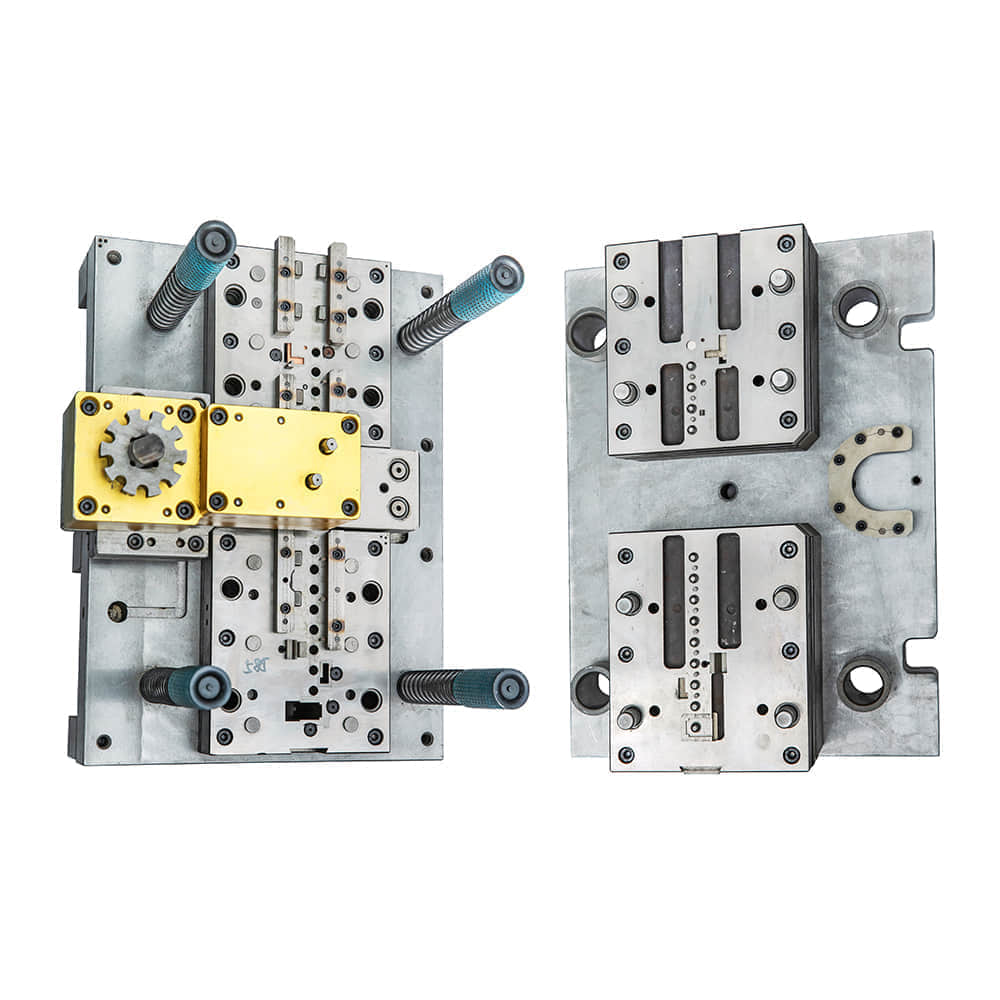

Metal stamping die manufacturers play a crucial role in the manufacturing industry, supplying essential tools that are fundamental in the production of various metal parts and components. Metal stamping is a process that involves using a die to shape and cut metal sheets into desired shapes and sizes. This method is widely used across various industries, including automotive, aerospace, electronics, and appliances, due to its efficiency and cost-effectiveness. This article explores the importance of metal stamping dies, the manufacturing process, and the qualities to look for when selecting a metal stamping die manufacturer.

Understanding Metal Stamping Dies

Metal stamping dies are specialized tools made from high-strength materials designed to shape metal sheets under high pressure. The process typically involves a series of steps, including blanking, punching, bending, and forming. Each die is specifically designed for a particular application, enabling manufacturers to create intricate designs with precision and high repeatability. This versatility makes metal stamping a preferred choice for mass production, where consistent quality is paramount. The Manufacturing Process The manufacturing process of metal stamping dies begins with the design phase, where engineers use Computer-Aided Design (CAD) software to create detailed blueprints of the die. This digital modeling allows for precise measurements and adjustments before any material is cut. Once the design is finalized, the manufacturing process begins, which generally consists of the following steps: