Injection molding is a crucial process in the manufacturing industry, providing efficient and cost-effective solutions for producing plastic parts. At the heart of this process lies the injection mold manufacturer, a key player responsible for designing and producing the molds that shape these parts. This article delves into the essential functions and significance of injection mold manufacturers in today’s economy.

Injection molding involves injecting molten material into a mold to create specific shapes. The process is widely used across various industries, including automotive, consumer goods, electronics, and medical devices. An injection mold manufacturer designs molds tailored to the precise requirements of each project, ensuring high-quality production and optimal performance.

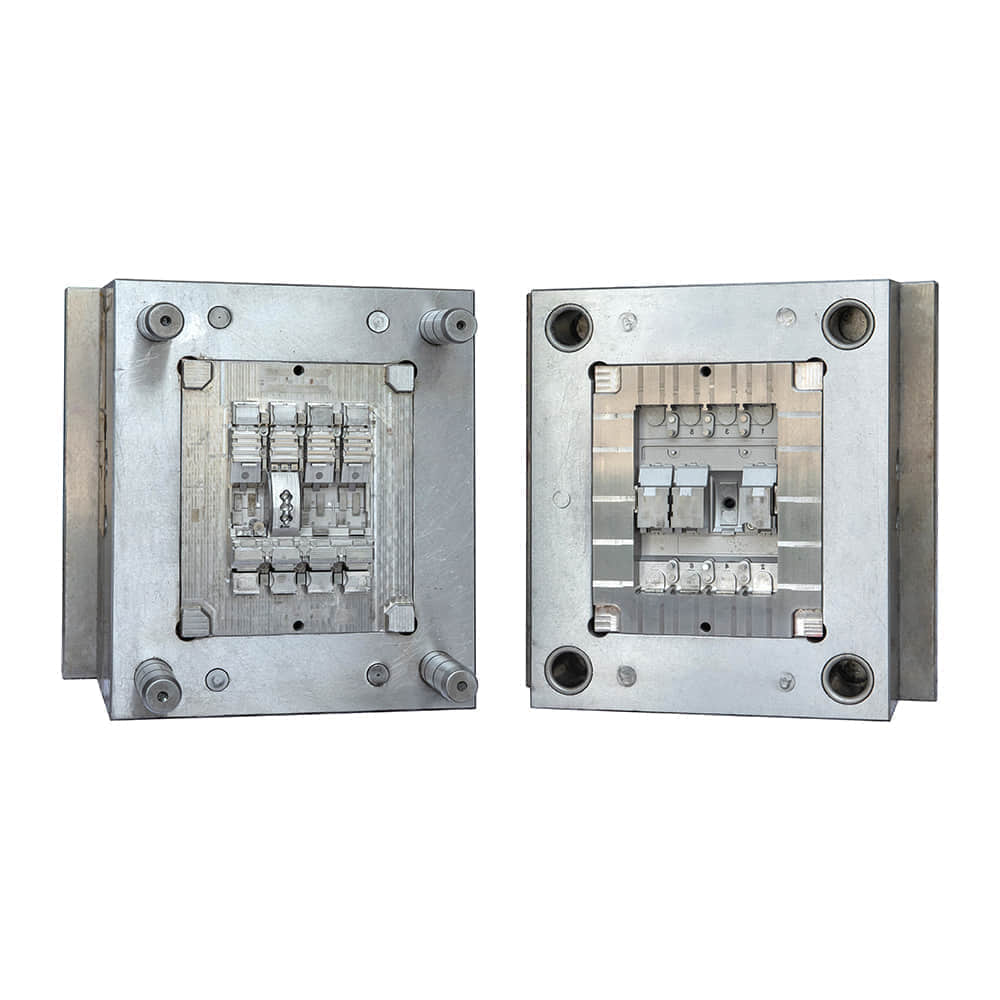

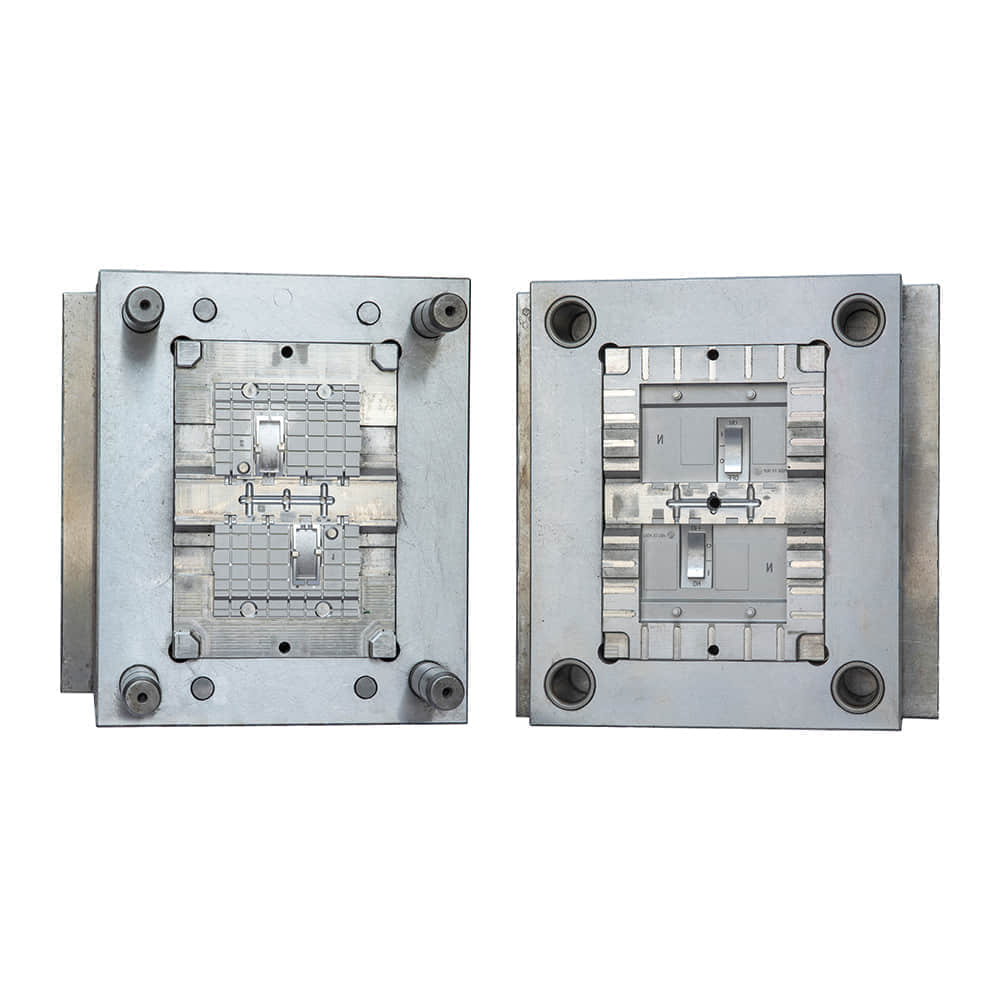

One of the primary responsibilities of an injection mold manufacturer is mold design. This requires a deep understanding of both the product’s specifications and the properties of the materials used. Manufacturers use advanced software tools like CAD (Computer-Aided Design) to create detailed mold designs that account for factors such as cooling efficiency, ejection mechanisms, and mold durability. The design phase is critical, as it lays the foundation for the mold’s performance and longevity. Once the design is finalized, the injection mold manufacturer proceeds to the production phase. This typically involves using high-precision machining equipment to create the mold components from materials like steel or aluminum. The choice of material can significantly affect the mold’s lifespan and the quality of the parts produced. Steel molds are more durable and suitable for high-volume production, while aluminum molds are often used for lower volume or prototype runs.