Relay circuits are essential components in the realm of electrical engineering and automation. They allow for the control of high-power devices using low-power signals, making them invaluable in various applications ranging from household appliances to complex industrial systems. This article delves into the fundamentals of relay circuits, their various applications, and the advantages they confer in electrical designs.

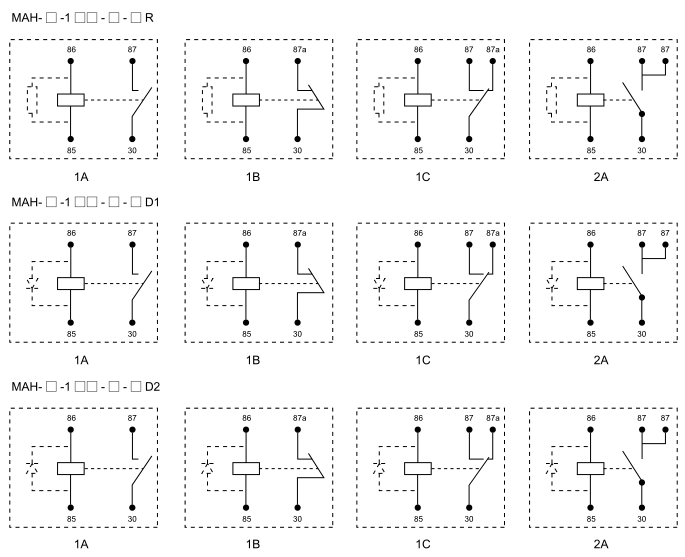

What is a Relay? A relay is an electromechanical switch that uses an electromagnetic coil to mechanically operate a switch. The unit typically consists of an electromagnet, a set of contacts, and a spring. When a small voltage is applied to the coil, an electromagnetic field is generated, which causes the armature to move, either opening or closing the contacts. Relays can be classified into various types, including electromagnetic relays, solid-state relays, and time-delay relays, each serving different functions based on their design and application. How Relay Circuits Work The operation of a relay circuit can be summarized in a few simple steps: