Electric stainless steel flange ball valves have become a critical component in modern industrial systems, particularly in applications involving the control and regulation of fluid flow. Their ability to offer precise control, durability, and efficiency makes them a preferred choice across various industries, including oil and gas, water treatment, chemical processing, and power generation. This article delves into the key features, advantages, and applications of electric stainless steel flange ball valves, and why they are essential for today’s industrial needs.

What is an Electric Stainless Steel Flange Ball Valve?

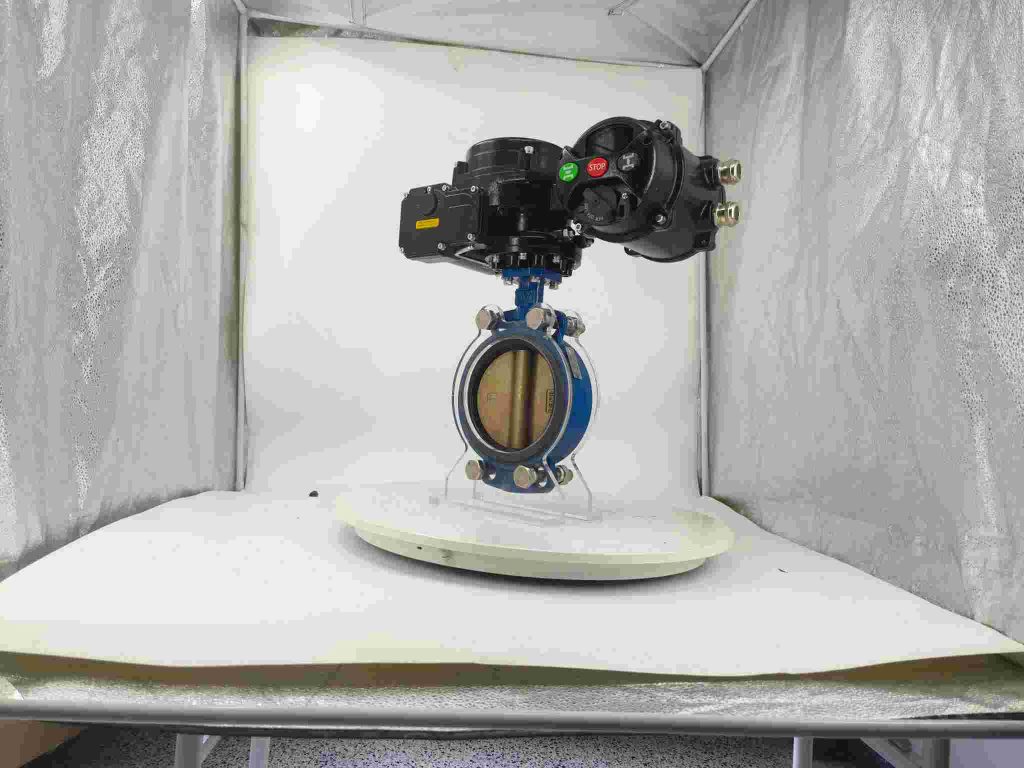

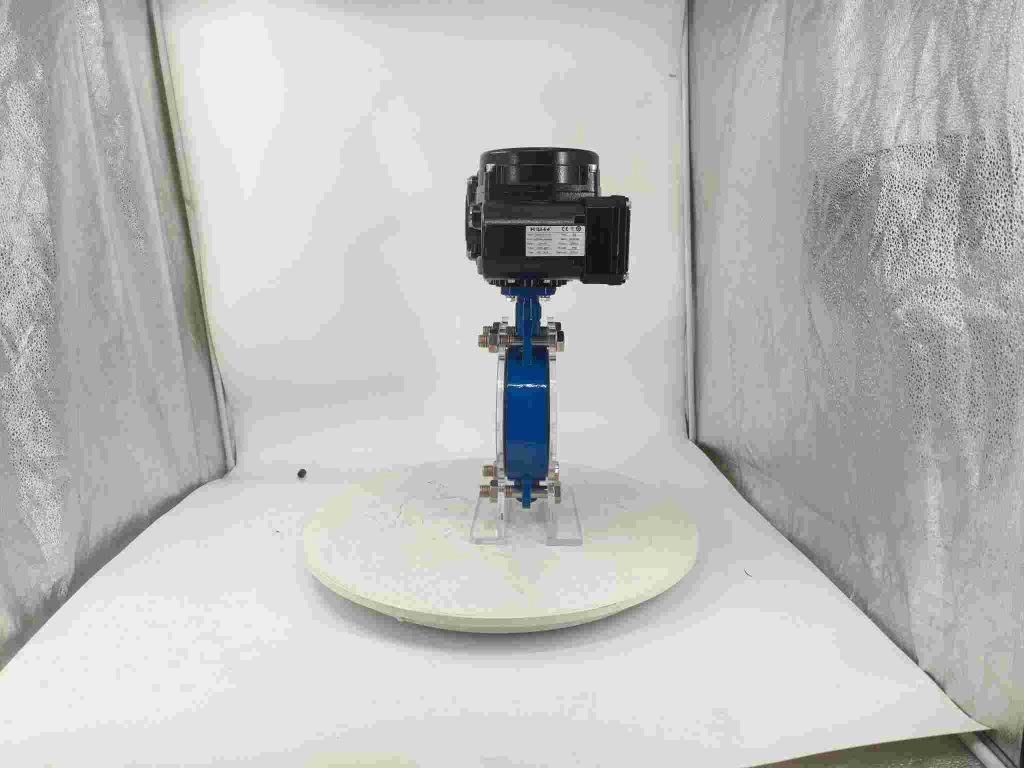

An electric stainless steel flange ball valve is a type of ball valve where the actuator is powered electrically to control the opening and closing of the valve. The valve itself is made from stainless steel, which provides exceptional resistance to corrosion, heat, and other environmental factors. The “flange” part refers to the valve’s method of connection to pipes—by bolting the valve to flanged pipe ends. This design ensures a tight, leak-proof seal and makes installation and maintenance relatively straightforward. The key component of this valve is the ball inside, which has a hole or port through its center. When the valve is open, the hole aligns with the pipe, allowing fluid to flow through. When the valve is closed, the ball rotates to block the flow. The electric actuator controls this rotation, providing automated and remote control of the valve.