Relays are integral components in modern electrical and electronic systems, serving as electrically operated switches that allow one circuit to control another. The core of their functionality lies in the Relay Electrical Diagram, a schematic representation that outlines how relays are wired and interconnected in a system. This article delves into the significance of relay electrical diagrams, their components, and their practical applications.

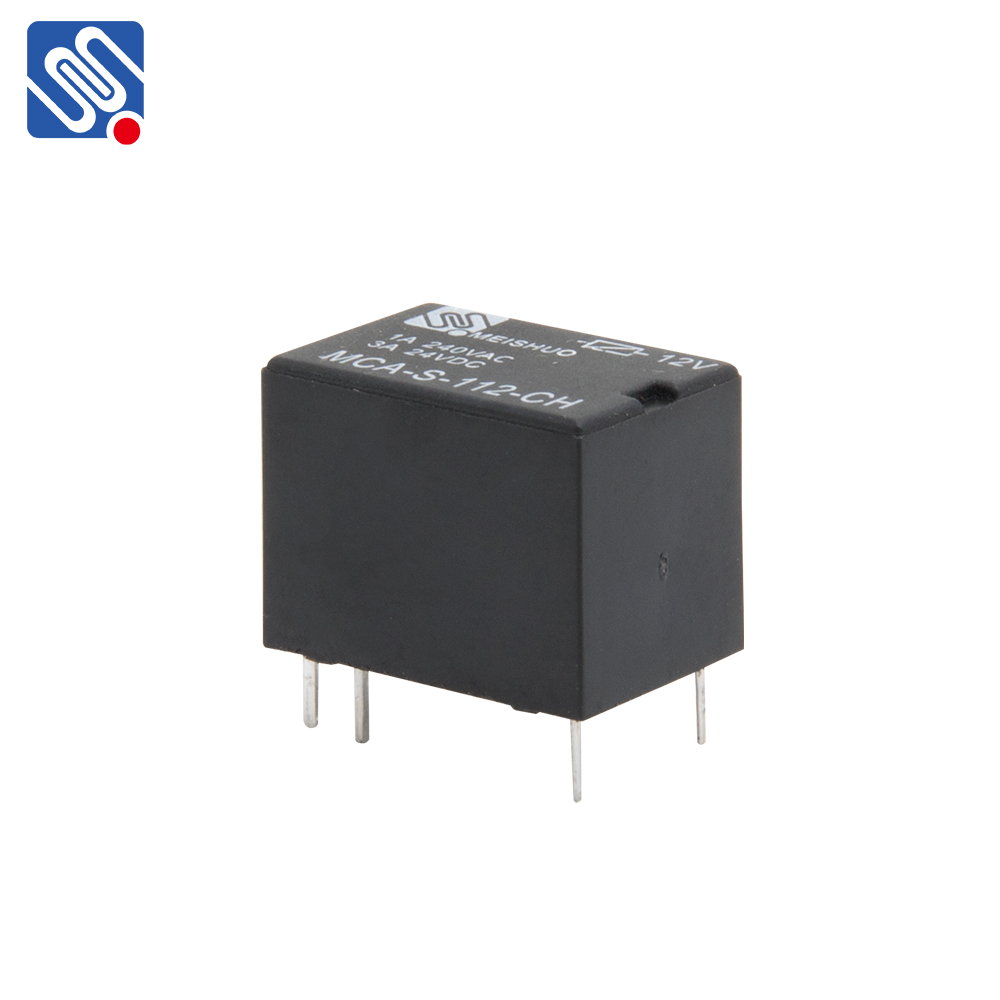

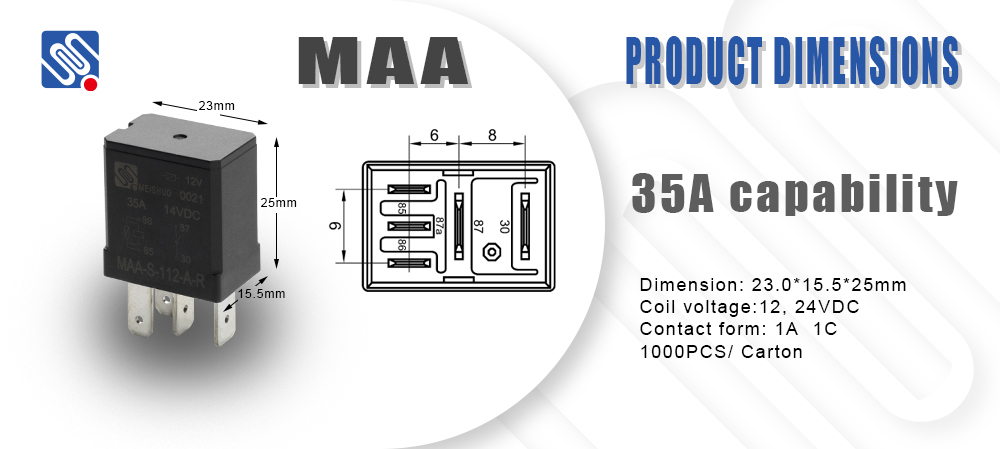

What is a Relay? A relay is a device that uses an electromagnet to mechanically operate a switch. When an electric current passes through the coil of the relay, it generates a magnetic field that attracts a lever, which in turn opens or closes the contacts of the switch. This allows the relay to control a high-power circuit with a low-power signal, making it a vital component in various applications, from automotive systems to industrial machinery. Components of a Relay Electrical Diagram A relay electrical diagram provides a visual representation of how a relay is integrated into a circuit. Key components illustrated in such diagrams include: