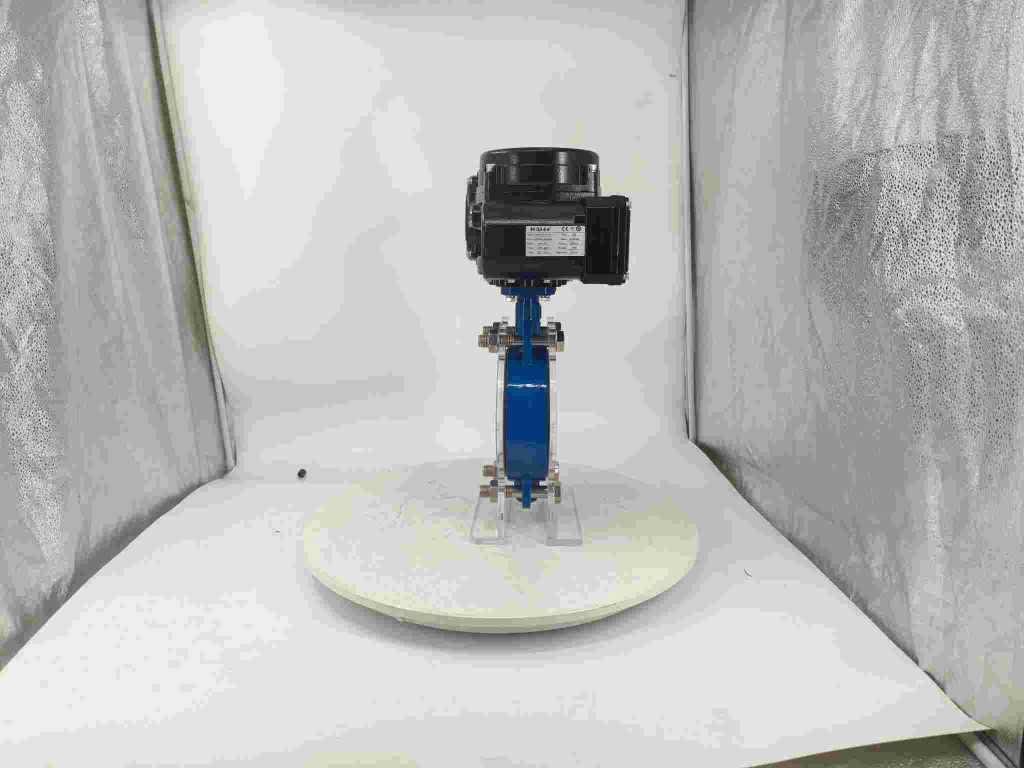

Explosion-proof electric stainless steel flange ball valves are specialized industrial components designed to meet the stringent demands of industries operating in hazardous and explosive environments. These valves combine a highly durable ball valve structure with an explosion-proof electric actuator, ensuring precise flow control while providing safety in volatile areas. Industries such as chemical processing, oil and gas, and petrochemical manufacturing depend on these advanced valve systems to control the flow of liquids and gases without compromising worker safety or equipment reliability.

What Makes Explosion-proof Electric Stainless Steel Flange Ball Valves Special?

The primary feature that sets these valves apart is their explosion-proof design. Hazardous environments—particularly those involving volatile gases or liquids—require valves that prevent sparks or heat from igniting flammable substances. The explosion-proof electric actuator ensures that no part of the valve, whether it be the actuator or wiring, could cause an ignition. These valves are typically built to meet international safety standards such as ATEX or IECEx, which outline the required features for equipment used in explosive atmospheres. The ball valve itself, made of high-quality stainless steel, offers outstanding resistance to corrosion, extreme temperatures, and high pressures. Stainless steel’s resistance to rust, pitting, and chemical attacks makes it a perfect material for environments where frequent exposure to harsh chemicals or saltwater may occur. Moreover, stainless steel is relatively easy to maintain and clean, ensuring longevity in high-demand applications.