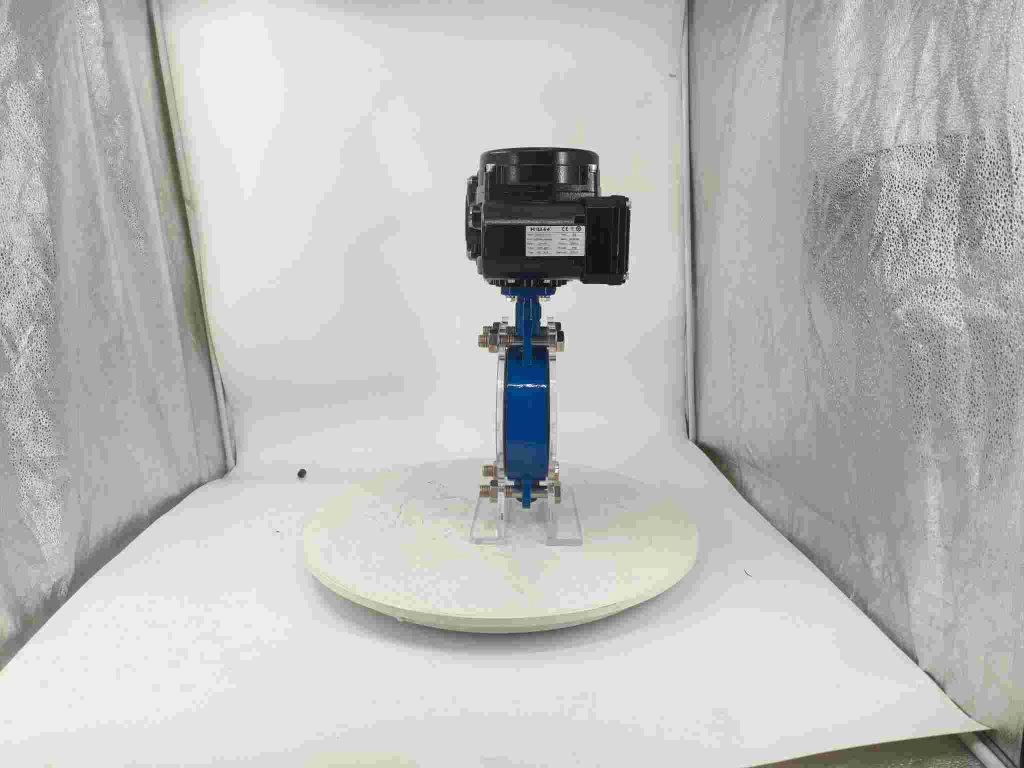

In modern industrial settings, ensuring the safety and integrity of control systems is crucial to preventing catastrophic failures, especially in high-risk environments like chemical plants, oil rigs, and power stations. One of the core components in achieving this level of safety is the SIL 3 Communication Relay. This specialized relay plays a pivotal role in meeting stringent safety standards and ensuring reliable communication in safety-critical applications.

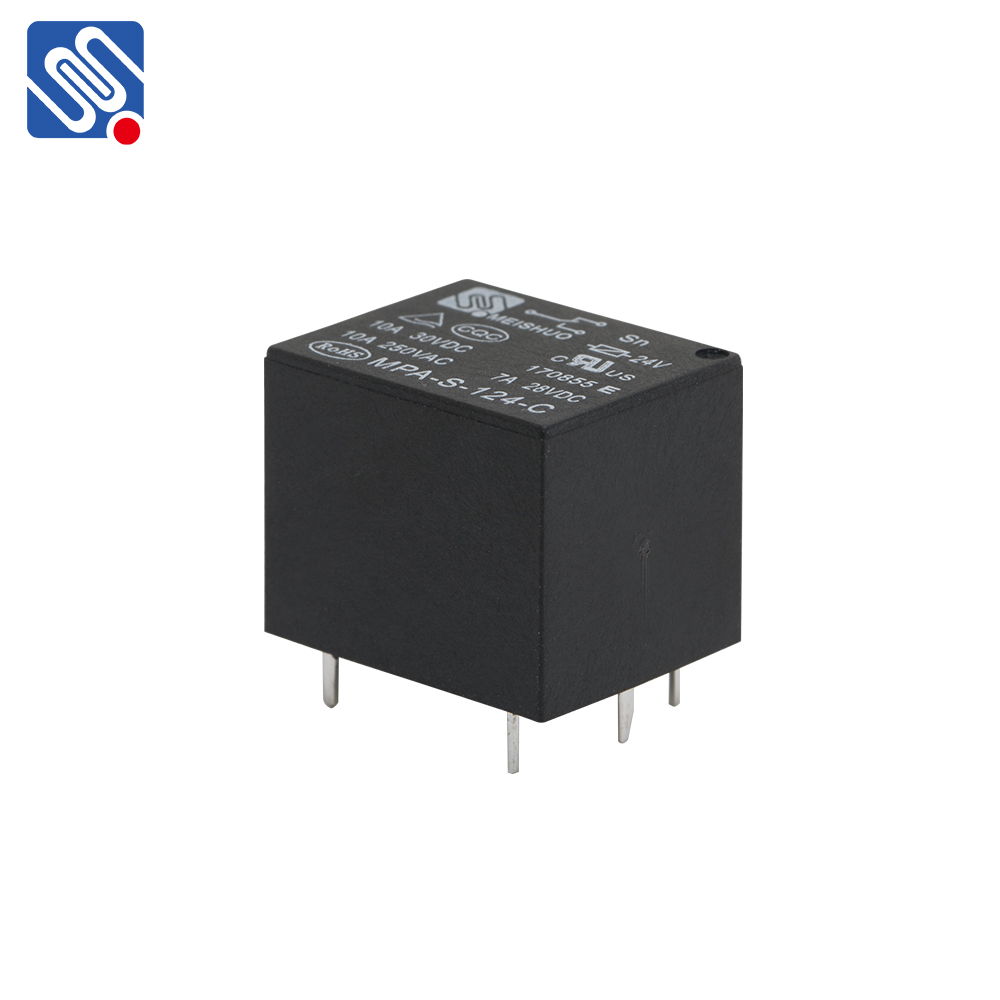

What is SIL 3? SIL, or Safety Integrity Level, is a concept defined by the international standard IEC 61508, which specifies the safety requirements for systems that control and monitor industrial processes. SIL is a measure of the reliability and effectiveness of a safety system in mitigating risk. There are four levels of SIL, with SIL 4 being the highest. SIL 3 is regarded as highly reliable, with a probability of dangerous failure less than 10⁻⁷ per hour. A SIL 3 Communication Relay is a type of safety relay that is designed to operate with this level of integrity, ensuring that the system it supports functions safely even in the event of a fault. These relays are typically used in critical applications where failure could lead to hazardous situations, such as emergency shutdown systems, fire alarms, or gas leak detection systems.