In industries where safety and operational efficiency are paramount, explosion-proof equipment plays a critical role in preventing accidents and protecting valuable assets. One such essential component is the explosion-proof electric butterfly valve, which ensures secure flow control in high-risk environments, including chemical plants, oil refineries, and gas distribution facilities. For businesses looking for top-notch performance and reliability, finding a reputable Explosion-Proof Electric Butterfly Valve OEM Manufacturer is key to ensuring the longevity and safety of operations.

Understanding Explosion-Proof Electric Butterfly Valves

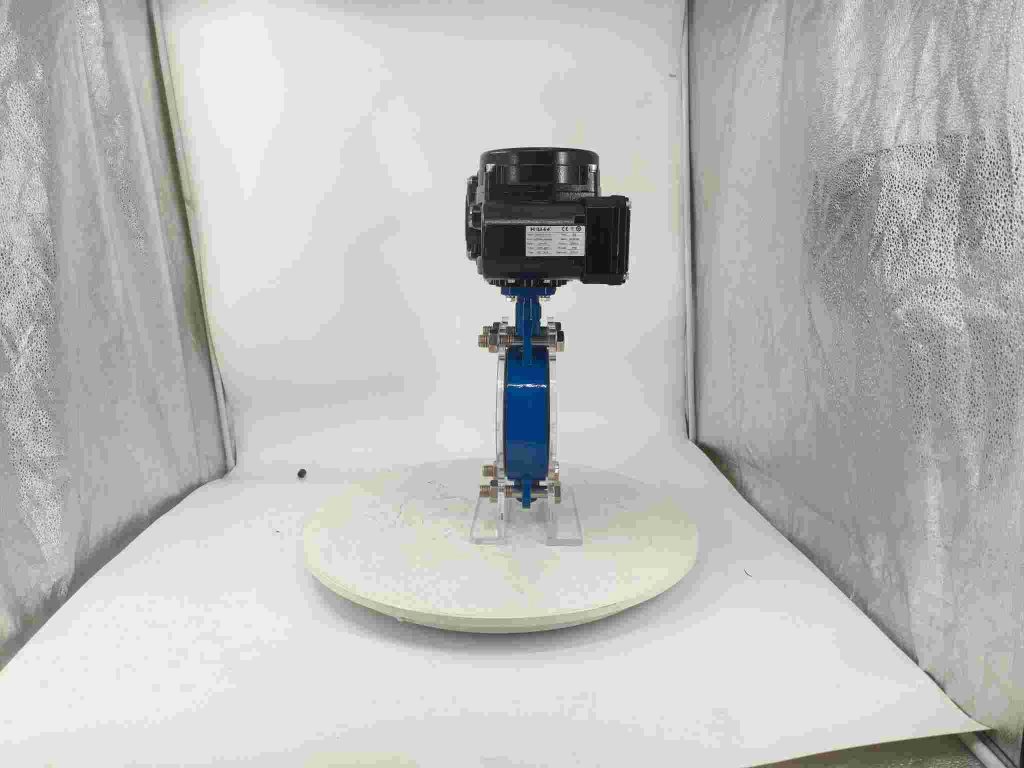

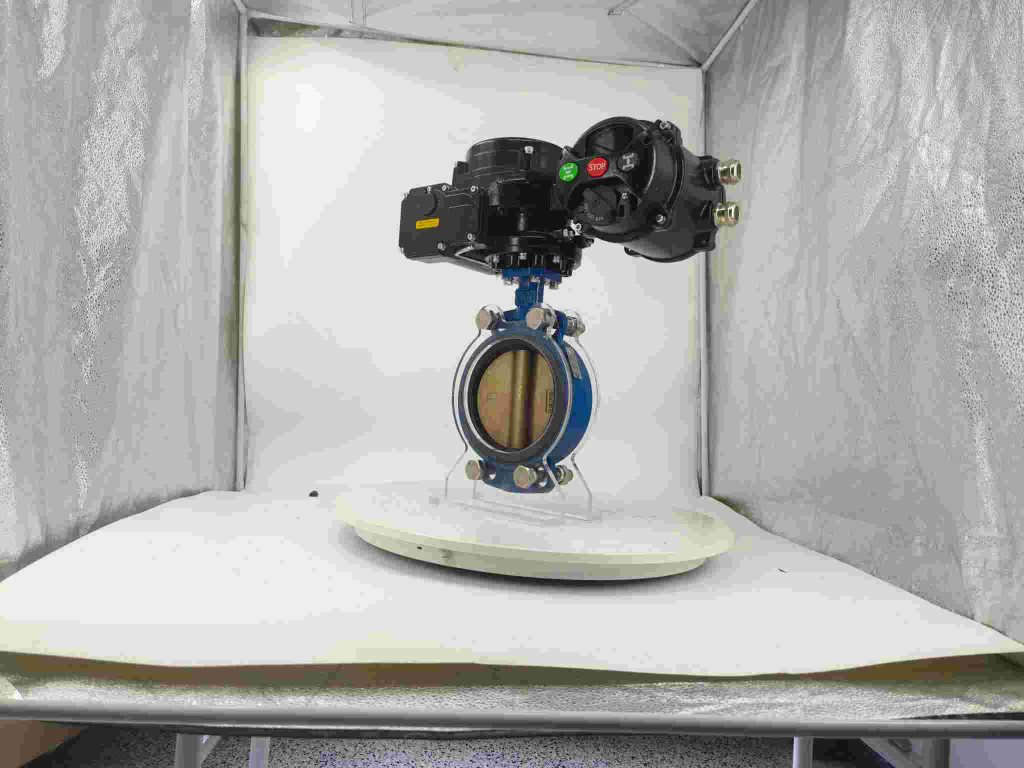

An electric butterfly valve is a type of quarter-turn valve used to regulate the flow of liquids or gases through a pipeline. The valve consists of a circular disc or “butterfly” that rotates to either open or close the passageway. When paired with an electric actuator, the valve can be automatically controlled, offering precise flow regulation in response to system commands. An explosion-proof electric butterfly valve goes one step further by being designed to prevent any potential ignition sources from causing explosions in hazardous environments. These valves are built to withstand extreme conditions and are typically used in areas where flammable gases, dust, or volatile liquids are present. The explosion-proof design ensures that any electrical faults or sparks within the valve assembly cannot ignite the surrounding atmosphere, making it an essential safety feature in industries like petrochemicals, pharmaceuticals, and mining.