In recent years, electric vehicles (EVs) have become increasingly popular due to their environmental benefits and advancements in battery technology. As the automotive industry shifts towards more sustainable transportation, the need for efficient, reliable, and safe power distribution systems has grown significantly. One critical component of these systems is the Power Distribution Unit (PDU) relay, which plays a vital role in ensuring that the high voltage and current used in EVs are managed and distributed safely. This article explores the importance of PDU relays in electric vehicles and their functionality within EV power distribution systems.

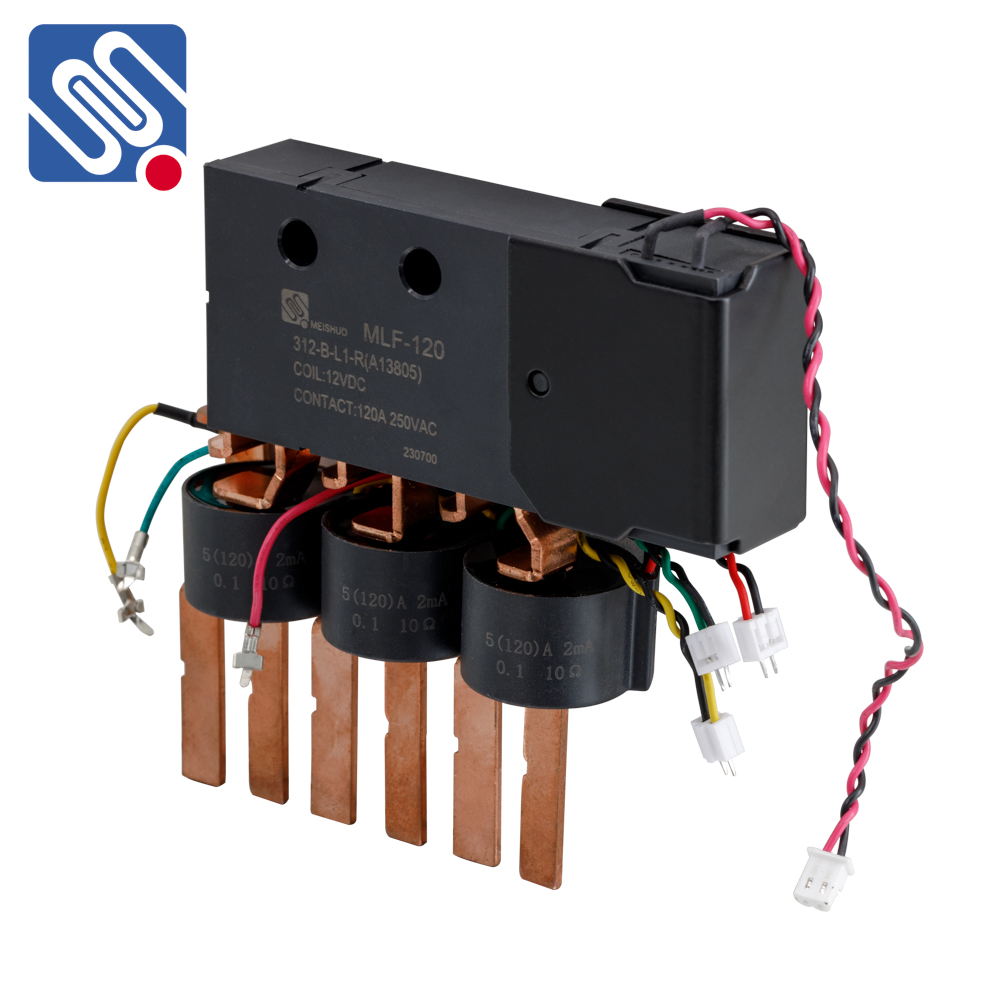

What is a PDU Relay? A Power Distribution Unit (PDU) is a key part of an electric vehicle’s high-voltage system. It is responsible for distributing power from the battery to various vehicle subsystems, such as the motor, air conditioning, and charging modules. The PDU relay is an essential part of this unit. It serves as a switch that controls the flow of high-voltage electricity in the system, providing protection, connectivity, and safety for both the vehicle and its occupants. The PDU relay acts as an interface between the battery and the vehicle’s electric components. It ensures that power is distributed only when necessary and that the system is protected in case of faults such as short circuits, overvoltage, or overload situations. Additionally, it is used to control the charging and discharging cycles of the battery, ensuring that energy is transferred efficiently and within safe parameters.