The Electric Flanged Butterfly Valve is a highly efficient and widely used valve system in industrial applications, particularly for controlling the flow of liquids, gases, and powders through pipelines. It combines the advantages of the butterfly valve’s simple design with the convenience of electric actuation, making it an ideal choice for automated systems that require precise flow control. This article delves into the construction, operation, advantages, and applications of the Electric Flanged Butterfly Valve, highlighting why it is a preferred choice in many industries.

Construction of Electric Flanged Butterfly Valve

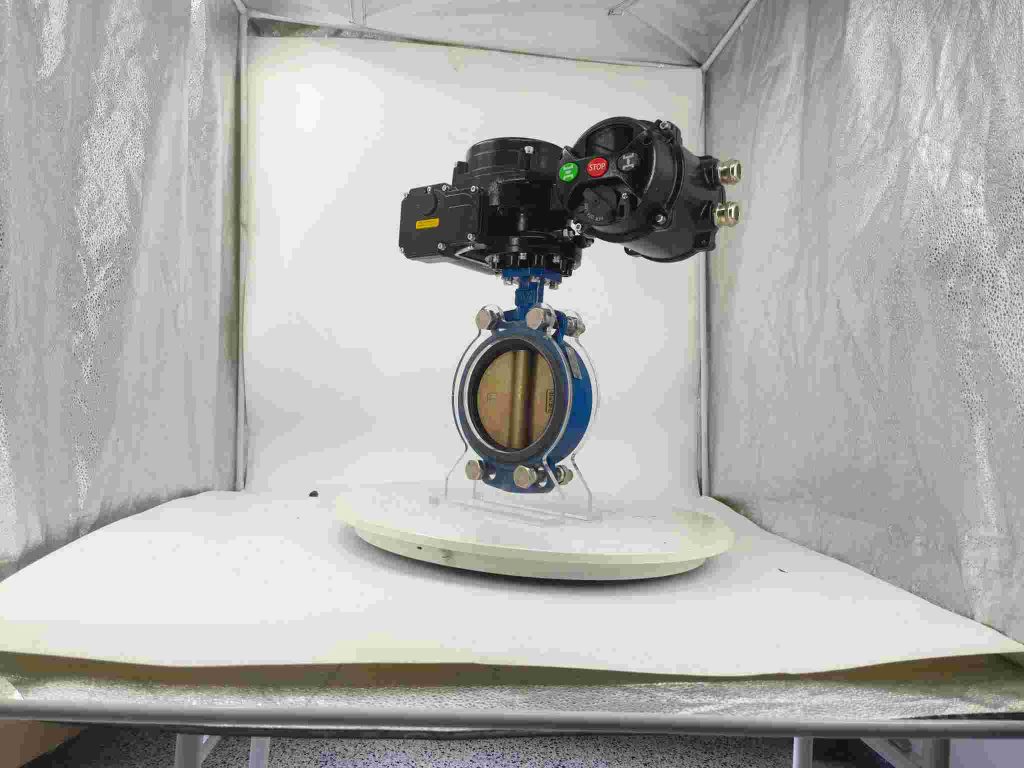

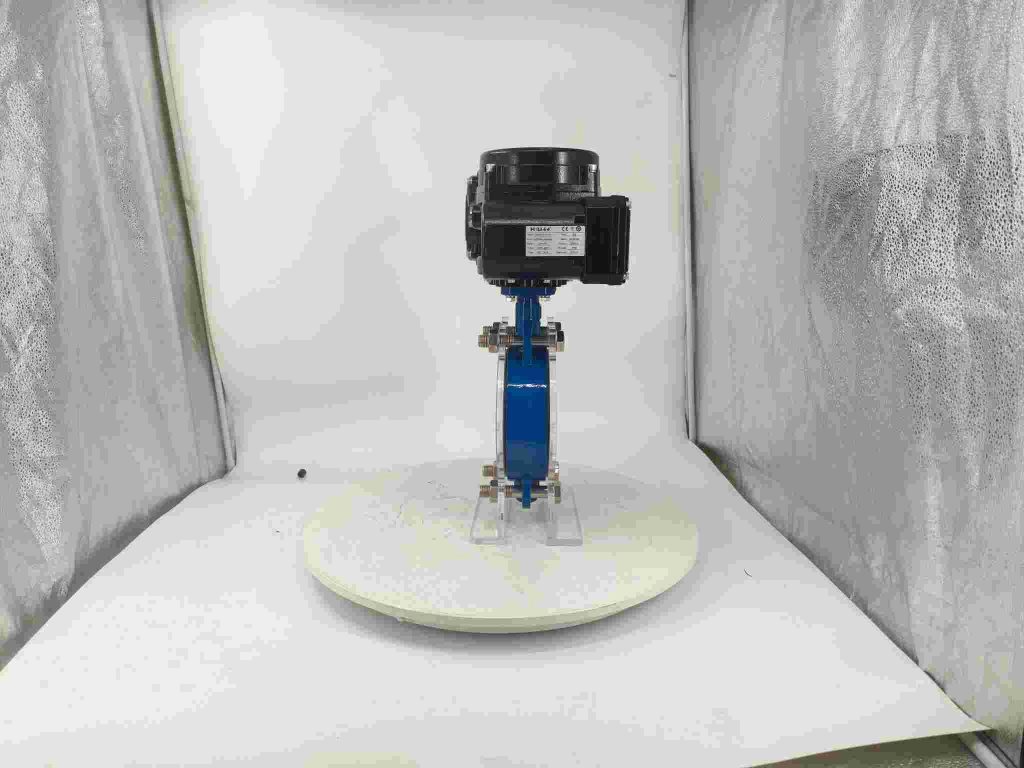

At its core, the Electric Flanged Butterfly Valve consists of several key components: the valve body, the butterfly disc, the seat, and the electric actuator. The valve body is typically made from durable materials like cast iron or stainless steel, ensuring that it can withstand high pressure and resist corrosion from aggressive media. The butterfly disc is the main component responsible for regulating the flow, and it is mounted on a rotating shaft that allows it to pivot open and closed.

The seat of the valve is designed to provide a tight seal around the butterfly disc, preventing leakage when the valve is closed. This seat is typically made from rubber, PTFE, or other materials, depending on the type of fluid the valve will control. The electric actuator is attached to the valve body, and it is responsible for driving the rotation of the butterfly disc. These actuators can be controlled remotely, allowing for automated operation of the valve through an electrical signal.