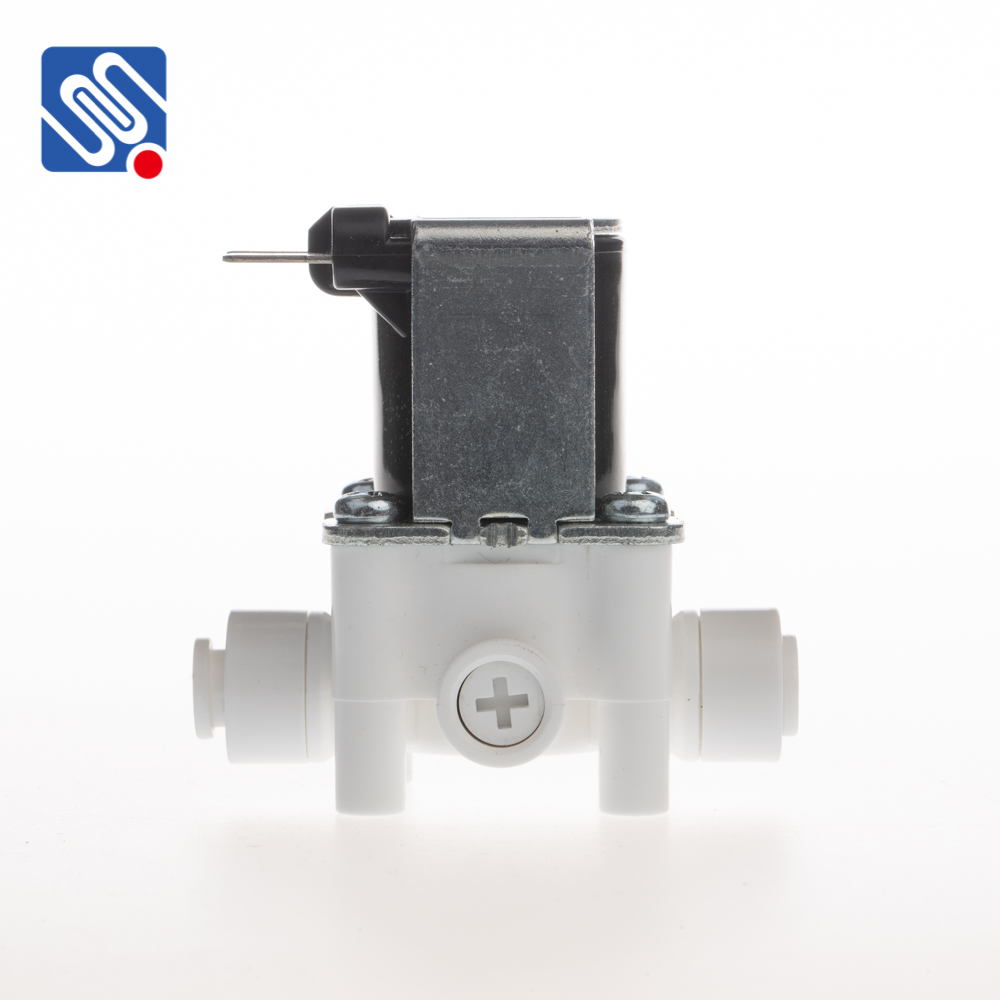

In the world of agriculture, efficient water management is critical for maximizing crop yield and conserving valuable resources. One of the essential components that facilitate effective irrigation systems is the valve. Among various types of valves used for irrigation, the WCB electric butterfly valve stands out due to its advanced design, efficiency, and reliability. This article explores the significance of the WCB electric butterfly valve in agricultural irrigation, its features, benefits, and applications.

What is a WCB Electric Butterfly Valve?

The WCB, or “Wrought Carbon Steel,” electric butterfly valve is a type of quarter-turn valve that utilizes a circular disc to control the flow of water. When the valve is opened, the disc rotates 90 degrees, allowing water to pass through. Conversely, when it is closed, the disc blocks the flow. The “electric” aspect refers to the actuator that opens and closes the valve electronically, offering precise control over the irrigation process. Advantages of WCB Electric Butterfly Valves Durability and Strength: Made from wrought carbon steel, WCB electric butterfly valves are robust and can withstand high pressure and temperature variations. This durability makes them ideal for agricultural environments where valves are exposed to various weather conditions.