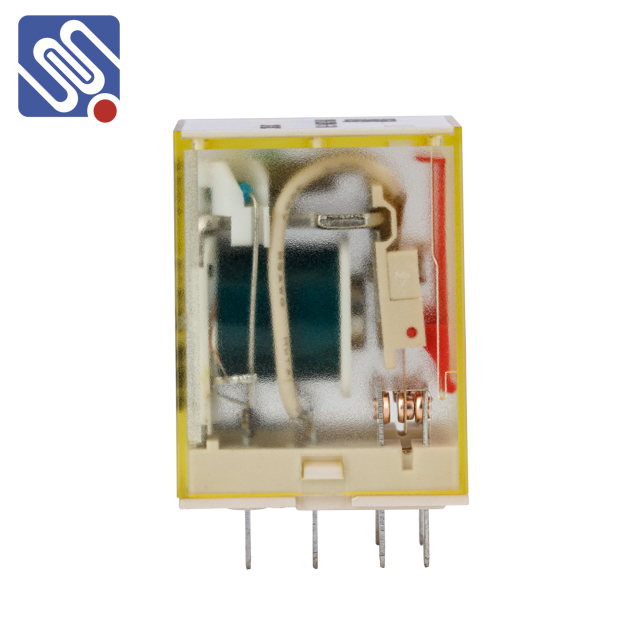

A PLC Control Relay plays a crucial role in the field of industrial automation, enabling efficient, reliable, and precise control of electrical systems. It is commonly used in conjunction with Programmable Logic Controllers (PLC) to automate various processes by switching electrical circuits on and off. This article will explore the working principles, applications, and advantages of the PLC Control Relay in modern industrial environments.

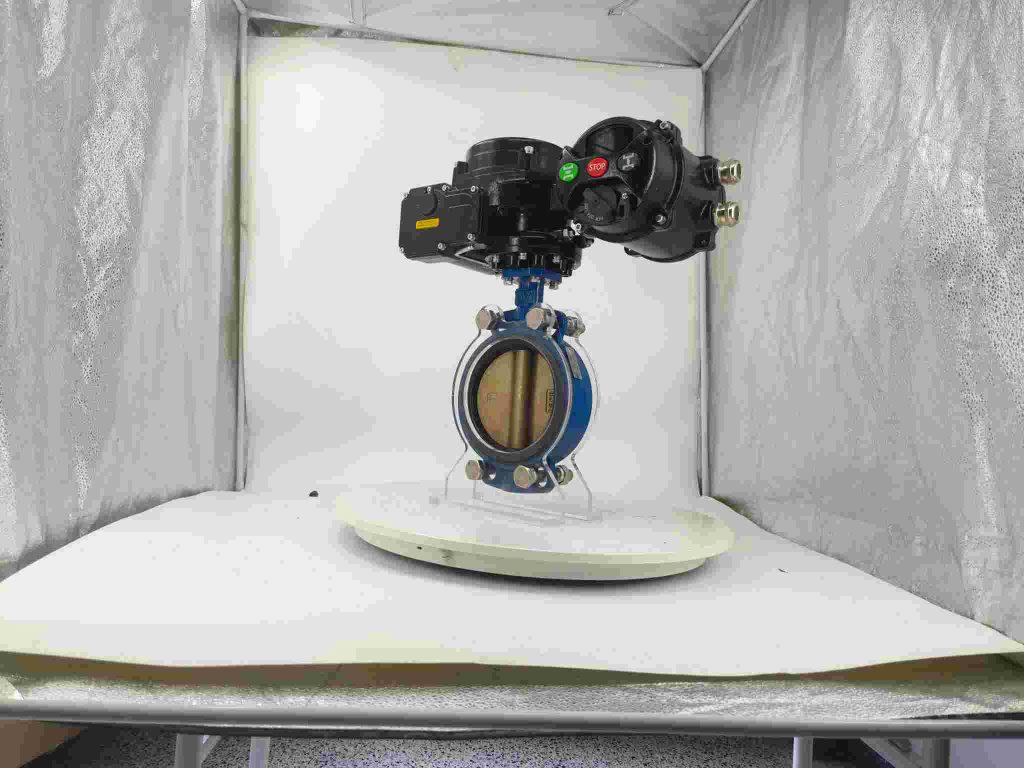

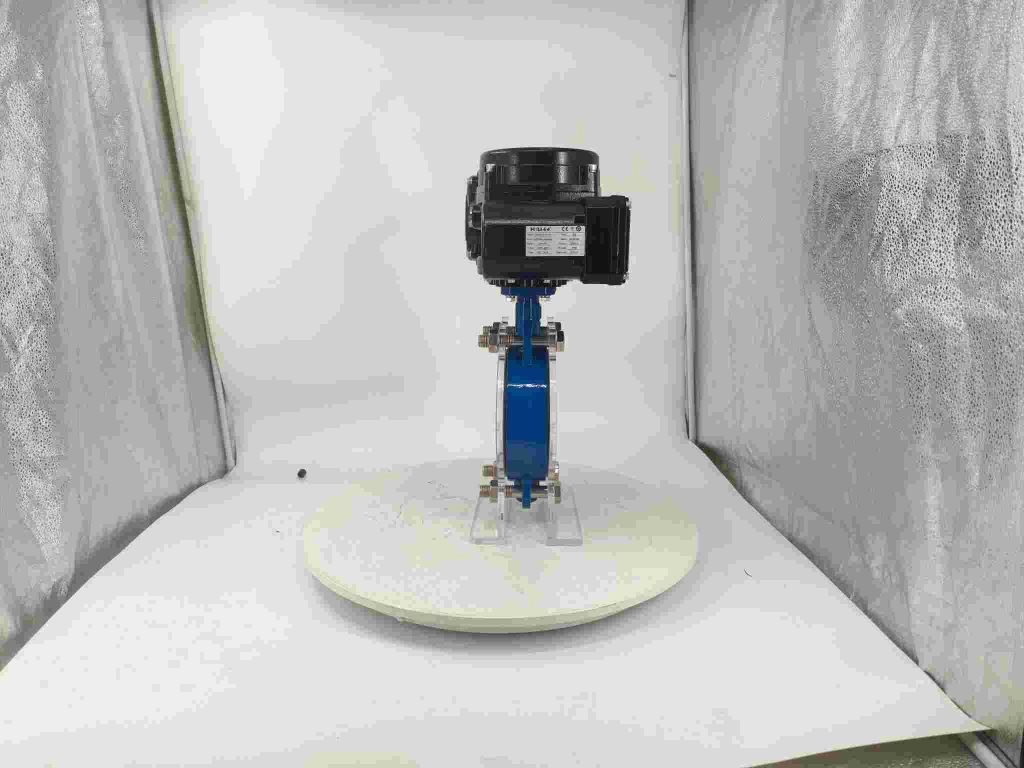

What is a PLC Control Relay? A PLC Control Relay is a device that works in tandem with a PLC system to control electrical circuits. The relay acts as a switch that is controlled by the PLC, which sends signals to the relay to either open or close the circuit. When the PLC’s output module sends a signal, the relay changes its state, thus controlling power to external devices such as motors, lights, or other machinery. A PLC is essentially a computer designed for industrial environments that automates the control of manufacturing processes. It reads inputs from sensors, processes the logic based on a pre-programmed sequence, and sends outputs to actuators like motors, valves, or relays. The PLC Control Relay serves as the intermediary between the PLC’s output and the devices requiring control.